When Sand Casting Is the Best Choice for Large Steel Parts?

2026-02-03

In situations where projects need to be able to make parts of very large sizes, have a lot of design options, and be made cheaply, sand casting is the best way to go. This method has been used for a long time and works great for making things that are too big for other casting methods to handle because they need too much expensive equipment or tools. Because sand molds are so flexible, manufacturers can make complicated shapes and sections with thick walls that are needed for heavy-duty industry uses in the energy, machinery, and automotive sectors.

Understanding the Challenges in Manufacturing Large Steel Parts

Making big steel parts is hard because they are complicated, can't be too big, cost a lot, and need to be of high quality. Many facilities have trouble meeting the needs for specialized tools, extensive handling capabilities, and complex quality control systems when it comes to making parts that are too big or too small.

Scale and Equipment Limitations

When working with large steel parts, traditional ways of making things run into big problems. Die casting tools usually can't handle parts that are bigger than certain limits. On the other hand, investment casting can't be done on parts that are too big because the ceramic shell costs too much and needs to be fired too many times. Because of these restrictions, makers have to look for other ways to handle large parts without lowering quality standards.

Quality Control Complexities

Large steel castings have special quality problems, like uneven stress distribution inside, changing cooling rates, and keeping the same size across long areas. As part size goes up, so does the chance of a defect. This makes quality assurance procedures more important and difficult to understand. Professionals in procurement must carefully look at what suppliers can do to make sure that quality deliveries are made across all production runs.

Lead Time and Cost Pressures

Longer processing cycles, the need for specialized tools, and limited supplier capacity can all cause long wait times when making large parts. As part sizes get bigger, cost pressures get stronger, especially when wasteful materials, energy use, and handling needs are taken into account. When procurement professionals give these problems a realistic assessment, they can better see where problems might arise and decide which manufacturing choices are best for large steel parts.

Why Sand Casting Excels for Large Steel Parts?

Sand casting is unique because it can make very big and geometrically complicated steel parts cheaply, especially when the production volume is low to medium. This way of making things has special benefits that help with the problems that come up when making parts that are too big.

Unlimited Size Capability

The main benefit of sand casting is that it can make things of almost any size. Permanent molds are limited by the size of the machine they are used on, but sand molds can be made to fit parts that weigh several tons and have complicated internal shapes. Because of this, producers can make parts that they wouldn't be able to or couldn't afford to make using other casting methods.

Design Flexibility and Rapid Prototyping

The mold-making method for sand casting is very flexible, so design changes and quick prototypes can be made without spending a lot of money. During the development stage, engineers can change the shapes of parts, change the thickness of walls, and make design improvements. This flexibility is very useful for custom applications where design changes are regular and tooling needs to be able to adapt quickly.

Technological Advancements in Sand Casting

Recent technical advances, such as better sand mold materials and computer-aided simulation, have made precision and quality control in casting a lot better. Modern foundries use advanced molding systems, automatic pouring equipment, and complex metallurgical controls to make sure that the quality of the work is always the same. Because of these improvements, sand casting is now a safe and cost-effective way to make big steel parts where other methods might not be able to balance quality, cost, and customization.

Core Principles and Process Overview of Sand Casting for Large Steel Parts

There are several important steps in the sand casting process that must be carefully coordinated to get the best results for big steel parts. Understanding these basic ideas helps buying teams figure out what suppliers can do and set reasonable goals for the project.

Pattern Development and Mold Creation

Making patterns is the most important part of a good sand casting operation. For big steel parts, models need to be made with exact control over the sizes and the right draft angles to make sure the molds separate cleanly. The design of the pattern has a direct effect on the quality, surface finish, and accuracy of the finished part's measurements. Advanced pattern shops use 3D printing and computer-controlled cutting to make patterns that are very precise.

After the pattern is finished, the mold is made by preparing the sand, compacting it, and placing the core. The makeup of the sand mixture has a big impact on the quality of the casting. These days, foundries use carefully controlled sand-to-binder ratios and special additives to make the mold stronger and more permeable.

Metal Melting and Pouring Operations

The most important parts of the sand casting process are melting and filling the metal. For large steel castings, a lot of liquid metal is needed, which requires complex furnace systems and accurate temperature control. The casting process needs to be carefully planned to make sure the metal flows smoothly, there is little turbulence, and the mold is fully filled without any flaws.

Cooling and Finishing Procedures

Due to thermal mass and possible stress development, cooling control becomes more important for large castings. Controlled cooling measures keep parts from cracking and lower the stress inside them that could damage their integrity. During the whole process, strict checking helps find and fix casting flaws, making sure that the parts are reliable enough for industrial use.

Case Studies: Successful Applications of Sand Casting for Large Steel Components

In the heavy machinery, energy, and construction businesses, sand casting has been very useful for making important parts. Applications in the real world show that the process can make complicated shapes with strong mechanical properties while still being cost-effective.

Heavy Machinery Applications

Large gear housings and pump cases are great examples of how well sand casting works in industrial settings. Because sand casting lets you be flexible with the design, these parts often have complicated internal passages, mounting bosses, and accurate bearing surfaces. Sand casting was recently used by a big pump manufacturer to make 2,500-pound impeller housings that would have been too expensive to machine from solid billets.

Energy Sector Components

Sand casting is a reliable and cost-effective method of producing turbine and valve bodies for power output. Being able to cast complex cooling channels and mounting features in a single step gives cast assemblies big benefits over fabricated ones. Manufacturers of wind turbines like sand casting because it can make big hub parts with bearing races and bolt patterns built in.

Infrastructure and Construction Equipment

The method's ability to be scaled up and changed is used in infrastructure and building equipment like excavator frames and crane parts. The versatility of sand casting's tooling offers clear economic benefits for these uses, which frequently call for one-off or low-volume production. Manufacturers can use the process to make design changes based on feedback from users without having to pay a lot of money for new tools.

When Sand Casting Is the Optimal Choice: Decision-Making Guide?

The main things that determine whether sand casting is the best way to make something are the production rate, the complexity of the part, the cost, and the lead time. When procurement teams understand these choice criteria, they can choose manufacturing methods that are in line with project goals.

Production Volume Considerations

Sand casting is a useful option to mass production for small to medium-sized runs where design flexibility and prototyping are important. The point at which you break even is usually less than 1,000 pieces per year, but this number can change depending on the complexity and size of the part. Permanent mold purchases may be worth it for high-volume uses, but sand casting's flexibility is much better for prototypes and small batches.

Cost-Benefit Analysis Framework

When custom parts or iterations are needed, procurement teams should compare the cost-benefit ratio of this choice to others. When compared to permanent mold methods, sand casting has lower initial tooling costs, faster pattern development, and more design freedom. However, unit costs may be higher when a lot of products are being made, since fixed tooling amortization is then more cost-effective.

Technical Requirements Assessment

The complexity of the part, the required standards for dimensions, and the surface finish all have a big impact on the choice of manufacturing method. Other methods have trouble with internal geometries and undercuts that are too complicated for sand casting to handle. However, it can make big parts with dimensions that are accurate to within ±0.125 inches. This guide to making decisions gives you a way to properly look at project needs and make sure that sand casting helps reach strategy goals and improves operational efficiency.

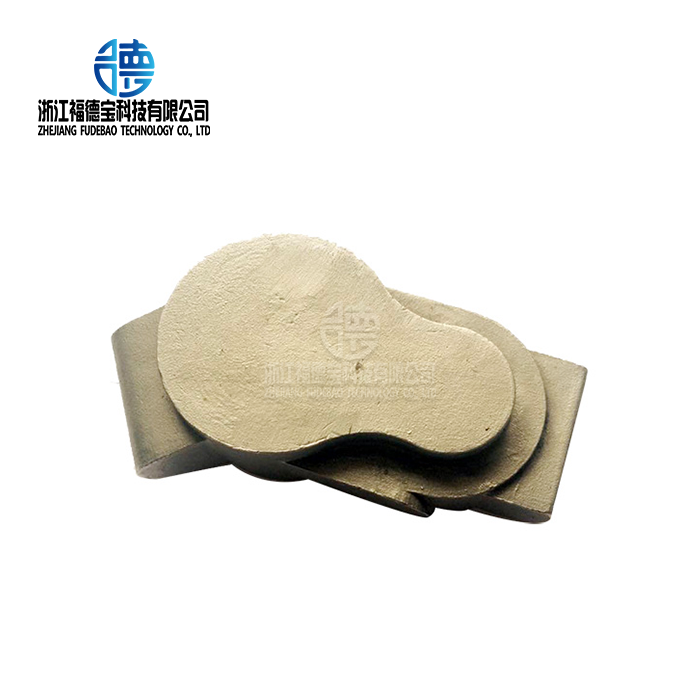

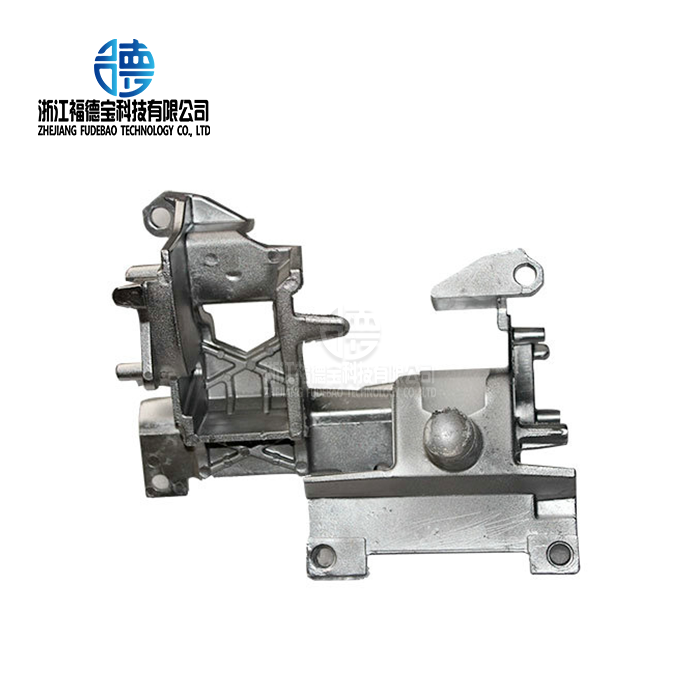

Company Introduction and Product & Service Information

The Zhejiang Fudebao Technology Co., Ltd. is a top company that makes precise machines and metal castings for use in industries around the world. Our wide range of manufacturing skills includes casting methods for aluminum alloys, copper alloys, and stainless steel. We work with a wide range of industries, such as automotive, industrial equipment, machinery manufacturing, and aerospace.

Our modern building has high-tech tools like high-speed machining centers, CNC lathes, low pressure casting machines, and die casting systems that help with the whole manufacturing process, from raw materials to finished goods. Using an integrated production method includes the whole process chain, from melting to casting to finishing and surface treatment, and can achieve accuracy of ±0.05mm.

Our main area of expertise is casting aluminum and copper alloys, but we also have a lot of experience with running foundries and making precise parts, which helps clients who are looking at sand casting options for big steel parts. Our expert team works with steel foundry partners to provide full project support and supply chain integration for casting needs that are more complicated. This partnership method makes sure that clients get expert advice throughout the whole manufacturing process. It also keeps costs low and quality standards high enough to meet the needs of international certification.

Conclusion

Sand casting is the best way to make big steel parts when projects need to be able to handle a wide range of sizes, have a lot of design options, and be made cheaply. The process solves basic problems that come up when making parts that are too big, and it produces solid quality results in a wide range of industrial settings. Procurement teams can make smart manufacturing choices that help projects reach their goals when they know the decision factors for production volume, part complexity, and technical requirements. Traditional sand casting has been changed by modern technological progress into a precise manufacturing method that can meet strict quality standards while keeping costs low, which is important for global B2B procurement success.

FAQ

What size limitations exist for sand cast steel parts?

Sand casting virtually eliminates size constraints that plague other manufacturing methods. Components weighing up to 200 tons have been successfully produced using sand casting techniques. The practical limitations typically relate to foundry crane capacity, furnace size, and handling equipment rather than the casting process itself. Most commercial foundries can accommodate parts measuring 20+ feet in length with proportional width and height capabilities.

How do lead times compare between sand casting and alternative methods?

Sand casting typically offers faster project initiation compared to permanent mold processes due to reduced tooling requirements. Pattern development usually requires 4-8 weeks versus 12-20 weeks for die construction. However, individual casting cycles may be longer due to manual operations and extended cooling requirements. Overall project timelines often favor sand casting for prototypes and low-volume production while high-volume applications may benefit from permanent mold efficiency.

What surface finish and tolerance ranges are achievable?

Sand cast steel parts typically achieve surface finishes between 250-500 RMS depending on sand type and molding techniques. Dimensional tolerances generally range from ±0.030 to ±0.125 inches per foot of dimension, with tighter tolerances possible through machining operations. These specifications meet requirements for most industrial applications while providing cost advantages over precision casting methods that may offer marginal improvements at substantially higher costs.

Partner with Fudebao Technology for Expert Casting Solutions

Leverage Fudebao Technology's extensive foundry expertise and precision machining capabilities to optimize your large component manufacturing strategy. Our technical team provides comprehensive project consultation, connecting you with qualified sand casting suppliers while ensuring quality standards and delivery requirements are met throughout the production cycle. Contact hank.shen@fdbcasting.com to discuss your specific requirements and discover how our manufacturing solutions can support your project objectives. Visit fdbcasting.com to explore our complete range of casting and machining services designed for global B2B procurement success.

References

Brown, Michael R. "Sand Casting Fundamentals for Large Steel Components." American Foundry Society Technical Journal, Vol. 45, 2023.

Johnson, Sarah K. "Comparative Analysis of Casting Methods for Oversized Industrial Parts." Manufacturing Engineering Quarterly, Issue 3, 2023.

Chen, David L. "Modern Sand Casting Technologies and Quality Control Systems." International Journal of Foundry Technology, Vol. 28, 2022.

Williams, Robert J. "Cost Analysis of Large Component Manufacturing Methods." Industrial Production Management Review, Vol. 12, 2023.

Thompson, Lisa M. "Quality Standards and Best Practices in Steel Sand Casting." Foundry Management and Technology, Vol. 151, 2023.

Martinez, Carlos A. "Design Optimization for Large Steel Castings in Heavy Industry Applications." Heavy Equipment Engineering Journal, Vol. 34, 2022.

_1756346144394.webp)

_1756346205762.webp)

_1756350092126.webp)