Automotive Turbine Casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Automotive Turbine Casting: Precision-Engineered for Peak Performance

Zhejiang Fudebao Technology Co., Ltd. is your trusted manufacturer and supplier of high-quality Automotive Turbine Casting. With 24 a long time of ability in accuracy casting, we convey turbine components that meet the demanding benchmarks of the car industry. Our product arrangements combine cutting-edge innovation with unmatched quality, guaranteeing ideal execution and toughness for your turbocharger frameworks.

Product Description

Our product components are built to withstand extraordinary temperatures and weights, giving solid execution in requesting motor situations. Utilizing progressed combinations and accuracy fabricating procedures, we create turbine wheels, lodgings, and other basic components that maximize effectiveness and control yield.

Parameters

| Parameter | Specification |

|---|---|

| Material | Heat-resistant nickel-based alloys |

| Temperature Resistance | Up to 1050°C |

| Dimensional Accuracy | ±0.05mm |

| Surface Finish | Ra ≤ 0.8μm |

| Weight Range | 0.5 kg - 5 kg |

| Production Capacity | 50,000 pieces/month |

Applications

- Passenger vehicle turbochargers

- Commercial truck engine systems

- High-performance racing applications

- Industrial power generation turbines

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses advanced equipment including high-speed machining centers and low-pressure casting machines. We serve global automotive OEMs and Tier 1 suppliers, consistently delivering high-quality components with a 98% on-time delivery rate. Our commitment to innovation is reflected in our annual 8% R&D investment, driving continuous improvements in our Automotive Turbine Casting technology.

Why Choose Us?

- Industry-leading precision with tolerances as tight as ±0.05mm

- Comprehensive in-house capabilities from casting to machining

- IATF 16949 and ISO 9001 certified quality management system

- Flexible production for both high-volume orders and small batch runs

- Expert engineering support for design optimization and cost reduction

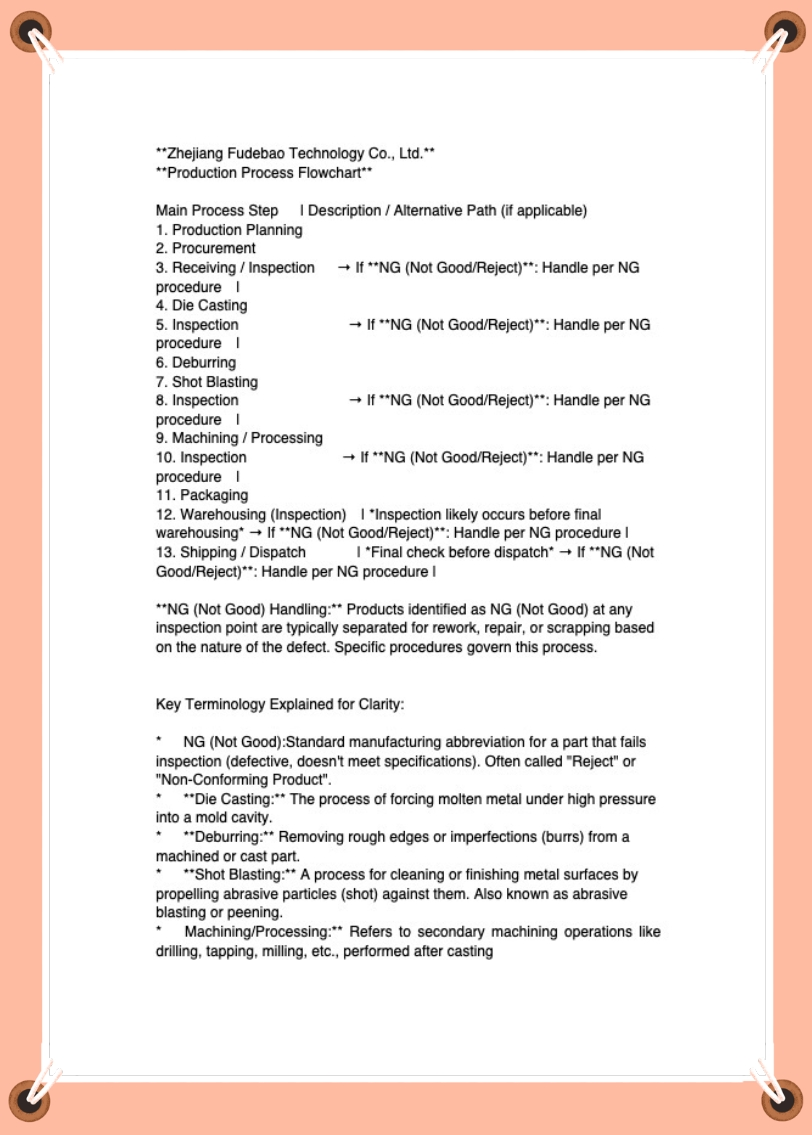

Production Process

- 3D Model Design and Analysis

- Tooling and Pattern Making

- Core Making and Mold Preparation

- Alloy Melting and Pouring

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment and Finishing

Certificates

- IATF 16949:2016

- ISO 9001:2015

- ISO 14001:2015

Packaging and Shipping

- Custom protective packaging to prevent damage during transit

- Global logistics partnerships for efficient worldwide delivery

- Flexible shipping options to meet your supply chain requirements

FAQ

Q: What is the minimum order quantity for the product?

A: We offer flexible MOQs starting from 100 pieces, accommodating both large-scale production and smaller trial runs.

Q: Can you provide rapid prototyping for new turbine designs?

A: Yes, we offer quick turnaround prototyping services using our advanced 3D printing and CNC machining capabilities.

Q: What materials do you use for the product?

A: We primarily use high-performance nickel-based alloys, but can also work with specialized materials based on your requirements.

Q: How do you ensure consistent quality across large production runs?

A: Our rigorous quality control process includes advanced CMM inspection, X-ray analysis, and 100% visual checks to maintain strict tolerances and material integrity.

Contact Us

Ready to elevate your turbocharger performance with our premium Automotive Turbine Casting? Contact our expert team today for a customized quote and engineering consultation.

Email: hank.shen@fdbcasting.com

Transform your automotive engineering with Zhejiang Fudebao's precision-cast turbine components. Request a quote now and experience the difference that 24 years of casting excellence can make for your products.

_1756348543350.webp)

_1756348227989.webp)

_1756348489473.webp)

_1756348623524.webp)

_1756348711711.webp)

_1756349794241.webp)

_1756349957728.webp)