bearer supporting bracket

texture:stainless steel

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:stainless steel

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Zhejiang Fudebao Technology Co., Ltd: Your Trusted Bearer Supporting Bracket Manufacturer

As a leading bearer supporting bracket manufacturer, Zhejiang Fudebao Technology Co., Ltd. offers premium quality, precision-engineered brackets for industrial applications. Our 24 a long time of mastery in metal casting and machining guarantees that our products meet the most noteworthy measures of toughness and execution. We pride ourselves on conveying cost-effective arrangements without compromising on quality.

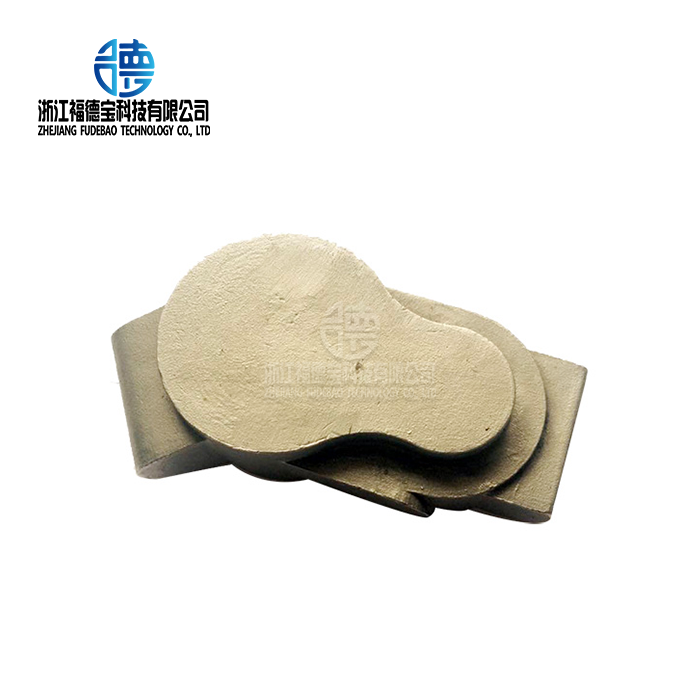

Product Description

Our products are planned to give strong back for different mechanical gear and apparatus. Made from high-grade aluminum amalgam, these brackets offer extraordinary strength-to-weight proportion, making them perfect for applications where both solidness and weight contemplations are pivotal. The precision-engineered plan guarantees ideal stack conveyance and life span.

Parameters

| Specification | Details |

|---|---|

| Material | Aluminum Alloy (6061-T6) |

| Finish | Anodized |

| Load Capacity | Up to 500 kg |

| Dimensions | Customizable (Standard: 200mm x 150mm x 100mm) |

| Weight | 1.2 kg - 2.5 kg (depending on size) |

| Mounting | Bolt-on (M10 bolts recommended) |

| Corrosion Resistance | High |

Product Details Pictures

Applications

Our bearer supporting brackets find extensive use in:

- Automotive assembly lines

- Heavy machinery support structures

- Construction equipment

- Aerospace component mounting

- Industrial robotics

- Energy infrastructure projects

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, has grown to become a benchmark in China's aluminum foundry industry. Our 3000㎡ facility in Zhuji, Zhejiang, houses state-of-the-art equipment for casting, machining, and surface treatment. We serve global clients across automotive, industrial equipment, and energy sectors, maintaining a reputation for precision, reliability, and innovation in metal part customization.

Why Choose Us?

- Expertise: 24 years of specialized experience in metal casting and precision machining.

- Quality Assurance: ISO 9001 certified with stringent quality control measures.

- Customization: Tailored solutions to meet specific industry requirements.

- Cost-Effectiveness: Direct manufacturing ensures competitive pricing without compromising quality.

- Innovation: Continuous R&D investment for product improvement and innovation.

Production Process

- Design and Engineering

- Mold Creation

- Aluminum Casting (Low Pressure or Die Casting)

- CNC Machining for Precision

- Surface Treatment (Anodizing)

- Quality Inspection

- Packaging and Shipping

Certificates

- ISO 9001:2015 Quality Management System

- CE Certification for European Market

- RoHS Compliance

- IATF 16949 (Automotive Industry Standard)

Packaging and Shipping

- Individually wrapped in protective foam

- Sturdy carton packaging for bulk orders

- Custom crating available for large shipments

- Global logistics partnerships for efficient delivery

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible ordering options, with a minimum order quantity of 50 pieces for standard sizes.

Q: Can you customize the products to our specifications?

A: Absolutely! We specialize in customization. Send us your requirements, and our engineering team will work with you to create the perfect solution.

Q: What is the lead time for bulk orders?

A: Typical lead times for bulk orders range from 3-4 weeks, depending on quantity and specifications.

Q: Do you offer samples before placing a large order?

A: Yes, we provide samples for quality assurance. Sample costs are often credited towards your first order.

Contact Us

Ready to elevate your industrial support systems with our high-quality bearer supporting brackets? Contact our expert team today for a personalized quote and technical consultation.

Email: hank.shen@fdbcasting.com

Trust Zhejiang Fudebao Technology Co., Ltd. for all your product needs. Let's build a stronger, more efficient future together!

YOU MAY LIKE

_1756352340434.webp)

_1756352400994.webp)