New energy motor shell

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Zhejiang Fudebao Technology: Your Trusted New Energy Motor Shell Supplier

At Zhejiang Fudebao Technology Co., Ltd., we specialize in manufacturing high-quality new energy motor shells for the automotive and renewable energy sectors. With 24 years of precision casting expertise, we deliver innovative, cost-effective solutions that meet the demanding requirements of OEMs and distributors worldwide. Our products are designed to enhance performance, improve thermal management, and support the growing electric vehicle and clean energy industries.

Product Description

Our new energy motor shells are engineered for optimal performance in electric vehicles, wind turbines, and industrial machinery. Crafted from lightweight yet durable aluminum alloys, these shells offer superior heat dissipation and corrosion resistance. We use advanced low-pressure casting techniques to ensure precision and consistency in every product.

Parameters

| Feature | Specification |

|---|---|

| Material | Aluminum Alloy (A356, A380) |

| Weight | 2.5 - 5 kg (customizable) |

| Dimensions | Customizable to client specs |

| Thermal Conductivity | ≥ 150 W/(m·K) |

| Surface Finish | Ra ≤ 0.8μm |

| Tolerance | ±0.05mm |

| Corrosion Resistance | Salt Spray Test >1000 hours |

Applications

- Electric Vehicle Motors

- Wind Turbine Generators

- Industrial Automation Equipment

- Solar Energy Storage Systems

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision metal casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses advanced equipment for the entire production process. We serve global clients in automotive, industrial equipment, and renewable energy sectors. Our commitment to innovation is reflected in our annual 8% R&D investment and multiple patents for enhanced product performance.

Why Choose Us?

- Quality Assurance: ISO 9001 and IATF 16949 certified, ensuring top-tier quality.

- Cost-Effective Solutions: In-house production reduces costs without compromising quality.

- Technical Expertise: Customization capabilities to meet specific client needs.

- Rapid Prototyping: Quick turnaround on small batch orders (5-500 pieces).

- Sustainability Focus: Eco-friendly processes aligned with global ESG standards.

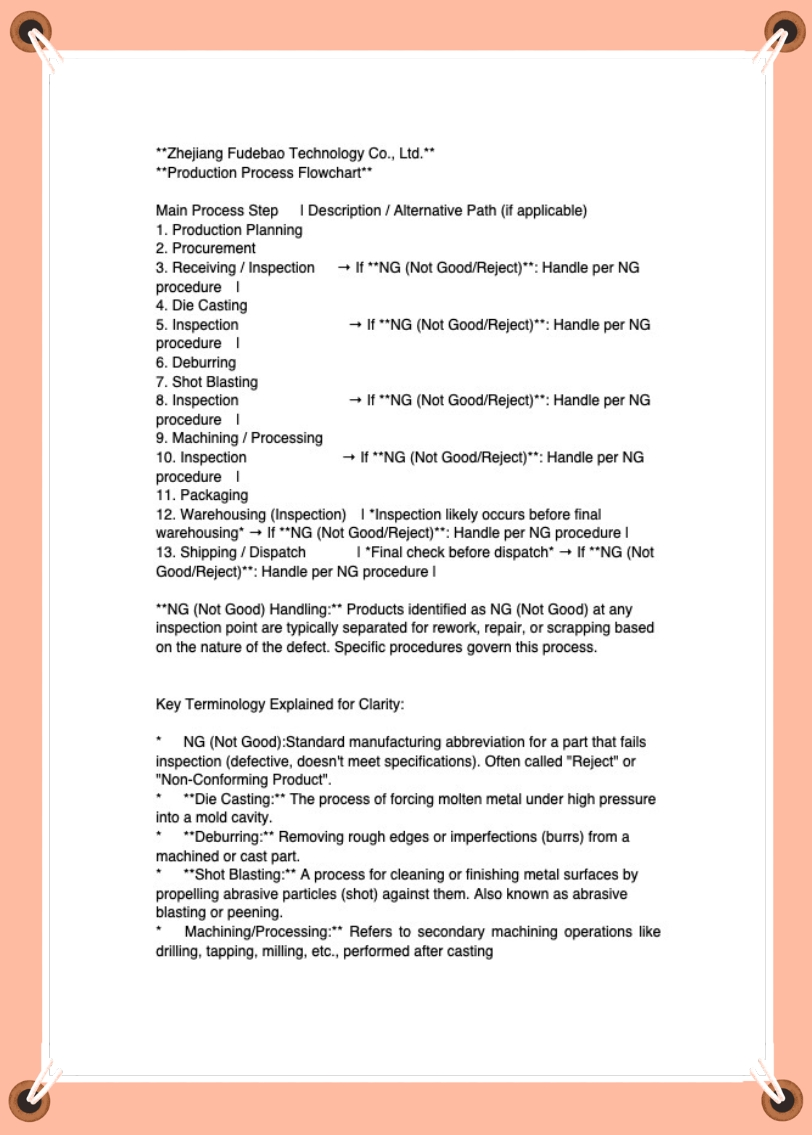

Production Process

- Design Consultation & DFM Analysis

- 3D Modeling & Simulation

- Tooling Development

- Low-Pressure Casting

- CNC Machining

- Quality Inspection

- Surface Treatment

- Final Assembly & Packaging

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949:2016 Automotive Quality Management

- ISO 14001:2015 Environmental Management System

- CE Certification for European Market

Packaging and Shipping

- Custom protective packaging to prevent damage during transit

- Global logistics partnerships for efficient worldwide delivery

- Flexible shipping options to meet urgent production needs

FAQ

Q1: What is the minimum order quantity (MOQ) for the new energy motor shell?

A1: Our standard MOQ is 100 units, but we offer flexibility for smaller orders and prototypes.

Q2: Can you provide samples before bulk production?

A2: Yes, we offer sample production services to ensure the product meets your specifications.

Q3: What is the lead time for bulk orders?

A3: Typical lead time is 4-6 weeks, depending on order volume and complexity.

Q4: Do you offer any warranty on your products?

A4: We provide a 12-month warranty against manufacturing defects under normal use conditions.

Contact Us

Ready to elevate your new energy projects with our high-performance motor shells? Contact our expert team today:

- Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology power your innovation with our precision-engineered new energy motor shells. Request a quote now and experience the difference of working with a leader in metal casting technology.

_1756347888208.webp)

_1756348543350.webp)

_1756348227989.webp)

_1756348780785.webp)

_1756349071334.webp)

_1756349146076.webp)

_1756349957728.webp)

_1756350092126.webp)