- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Fast shipping

Price Protection

After-sale guarantee

24-hour Customer Service

About Us

Zhejiang Fudebao Technology Co., Ltd. --24 years of precision casting quality, global industrial parts customization experts

Company history: from Hangzhou to Zhuji, 24 years of deep cultivation in the casting field

In 2001, Fudebao Technology (Hongcheng Precision Machinery) started its journey in Hangzhou, China, and started the exploration of metal casting processing with "precision casting every piece" as its initial intention;

In 2015, in order to meet the needs of large-scale production, the company moved to Zhuji, Zhejiang Province, China, with 3000㎡ self-owned factory buildings and full-link production system, officially entering a new stage of "scale + specialization" development;

For 24 years now, we have always focused on aluminum alloy, copper alloy, stainless steel and other metal casting and precision machining, serving the global automotive, industrial equipment, machinery manufacturing, aviation ships and other fields, from middleman cooperation to direct supply of American HAAS automation machine tools, ESS energy storage batteries and other international brands, with strength to become "China aluminum foundry benchmark enterprise."

Core advantages: from equipment to service, full link competitiveness

Advanced equipment supports precision manufacturing

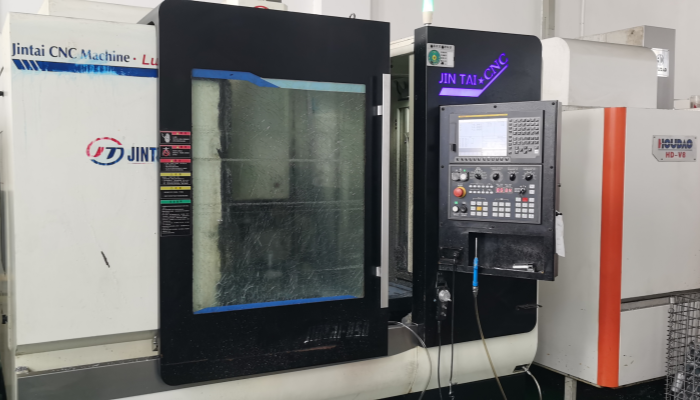

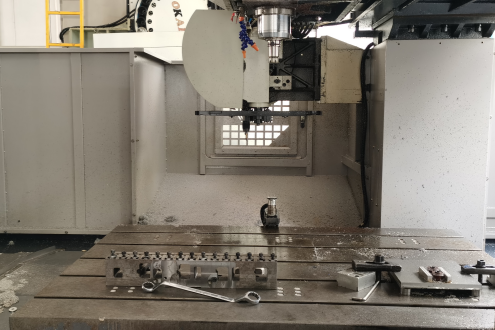

The factory is equipped with core equipment such as high-speed machining center, CNC lathe, low pressure casting machine, die casting machine, etc., covering the whole process of "melting-casting-finishing-surface treatment", supporting one-stop delivery from blank to finished product, with accuracy up to ±0.05mm, meeting the high requirements of automobile precision parts, medical equipment shells and other scenarios.

Multi-process, adapt to complex needs

24 years of technology precipitation, we are proficient in:

· Aluminum casting: aluminum alloy sand casting, low pressure cast aluminum, aluminum mold casting (wall thickness 3-20mm, tensile strength ≥280MPa);

· Copper casting: copper alloy precision casting (conductivity ≥98%IACS, seawater corrosion resistance>50 years);

· Stainless steel processing: food grade/industrial grade stainless steel parts (surface treatment Ra≤0.8μm, in line with FDA/ROHS standards);

· Gravity casting: high toughness castings (elongation>5%, suitable for engineering machinery support).

Global customers, verify quality strength

Cooperation customers cover well-known enterprises at home and abroad:

· Indirect services: automobile OEMs, industrial robot manufacturers, large-scale engineering equipment manufacturers;

· Direct supply: American HAAS (core parts of automatic machine tools), ESS (energy storage battery box), domestic head car enterprises (chassis structural parts), etc., with "zero return rate" and "98% accurate delivery rate" to win long-term trust.

Main products and services: customized metal parts, empowering global industries

We focus on high-precision, high-reliability, and extreme environment resistant metal parts, and provide solutions for multiple industries:

• Automotive: engine mounts, chassis structural parts, steering knuckles (low-pressure casting, weight reduction of 15% and still maintain strength);

• Industrial equipment: robot joint housing, servo motor base, hydraulic valve block (stainless steel/aluminum alloy, wear resistant);

• Energy field: energy storage battery box, photovoltaic inverter heat sink (copper/aluminum alloy, efficient thermal conduction);

• Construction engineering: valve housing, pipe connector (sand casting, high pressure/anti-aging);

• Customized service: support drawing customization (STEP/IGES format), small batch trial production (5-500 pieces), surface treatment (anodizing/electrolytic polishing/passivation).

Our Equipment

Expansio applicationis missionum

Expansio applicationis missionum

Expansio applicationis missionum

R&D patents: innovation-driven, mastering core technologies

As a science and technology enterprise in Zhejiang Province, we have obtained a number of independent research and development patents based on the concept of "technology-enabled manufacturing":

• Structural optimization: syringe bracket for dispensing machine (lightweight design, weight reduction of 20%), robotic arm joint (high rigidity connection);

• Functional enhancements: X-axis motor base (optimized heat dissipation slot, 30% higher temperature resistance), wall washer end cover (waterproof and dustproof IP67);

• Material innovation: main control frame (aluminum alloy + rare earth element modification, fatigue life extension by 50%).

The patented technology is directly applied to the product, helping customers reduce the comprehensive cost by 10%-15% and improve the stability of product performance.

Fifth, the brand culture: based on the letter, to the quality of the far-reaching

Corporate vision: to become the preferred partner for global industrial metal parts customization;

Core values: focus (24 years of deep cultivation), innovation (8% of annual R&D investment), win-win (grow together with customers);

Service commitment: From drawing review to delivery and after-sales, the whole process is followed up transparently (cloud sharing of production progress), and free DFM analysis (weight reduction/cost reduction suggestions) is provided, so that cooperation is more worry-free.

Contact us now: upload your drawings (PDF/STEP format), get a free process feasibility report + exclusive quotation, and let Fortune Treasure Technology "precision casting value" for your industrial components!