CNC Machining vs 3D Printing for Rapid Prototyping

2026-02-04

When looking at CNC machining and 3D printing for rapid prototyping, they are both very useful for modern production in their own ways. Through subtractive manufacturing processes, CNC machining achieves high levels of accuracy and surface quality. This makes it perfect for making useful prototypes that need tight tolerances and materials that are good enough for production. 3D printing, on the other hand, is great for making designs that can be changed quickly and easily. Which one to use depends on the needs of the job, such as the material's properties, the accuracy of the measurements, the amount of work that needs to be done, and the time constraints. Knowing these differences helps engineers and people who work in buying choose the best prototyping method for their needs.

Understanding Rapid Prototyping Technologies

Modern fast prototyping includes two very different ways of making things that play different roles in the process of developing a product. Each technology works in a different way and has its own benefits for different testing situations.

CNC Machining Fundamentals

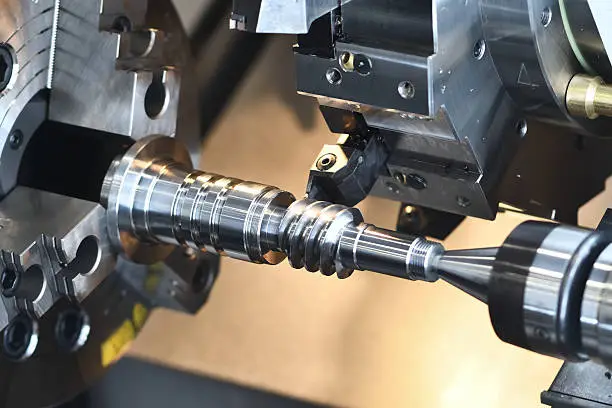

In subtractive manufacturing, computer-controlled cutting tools take away material from solid workpieces to make precise parts. This is what CNC machining does. Multi-axis machining centers with different cutting tools are used in this technology to make complicated shapes with great accuracy in the dimensions.

The process starts with setting up the CAD file and programming the toolpath. Next, the workpiece is put together, and automatic machining operations are run. Modern CNC systems can work with a wide range of production-grade materials, such as aluminum alloys, stainless steel, titanium, and industrial plastics, and can achieve tolerances as tight as ±0.001 inches.

CNC machining is great for making samples that work and look a lot like production parts in terms of the material properties and surface finish. This feature is especially useful for checking the strength of mechanical assemblies, making sure they meet load-bearing standards, and testing durability in real-life situations.

3D Printing Technologies Overview

Additive manufacturing techniques, such as 3D printing, build things from digital models one layer at a time. Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) are the most popular methods. Each one works with different types of materials and has different surface quality features.

FDM technology uses heated nozzles to push thermoplastic strands out, which makes it easy to use and inexpensive for testing ideas. SLA uses ultraviolet lasers to harden liquid photopolymer resins, making surfaces that are smooth enough for samples with lots of details. Laser energy is used in SLS to fuse powdered materials together, which lets complex internal shapes be made without the need for support structures.

These additive processes give engineers a lot of freedom in their designs. They can make complex internal channels, organic shapes, and assemblies that would be impossible or too expensive to make with standard methods. Modern 3D printers can now use a wider range of materials, from simple plastics to metal powders and ceramic mixtures.

Comparing CNC Machining and 3D Printing for Rapid Prototyping

When deciding between CNC machining and 3D printing, many performance factors that directly affect the success of prototyping must be carefully considered. By understanding these differences, you can make an informed choice based on the needs of your job.

Speed and Turnaround Time Analysis

3D printing usually has faster setup times and can make many versions of a plan quickly without having to change the tools. Simple prototypes can be made in hours, and changes to the design only need to be made to the files, not the toolpath code. Because it works faster, additive manufacturing is great for testing ideas early on and making changes to designs over and over again.

CNC machining takes longer to set up because of the time needed to choose the tools, fix the item, and check the program. But once they are set up, cutting often finishes faster than 3D printing, especially for parts that are bigger or more complicated. In addition, the subtractive process doesn't need long steps for post-curing or support removal, which are popular in additive manufacturing.

When comparing speeds, production number is a very important factor. In 3D printing, the time it takes to make a part stays the same no matter how many there are, but in CNC machining, the setup time is spread out over many pieces, which saves time. Machining methods are often better for mass production of identical prototypes, especially when using multi-cavity fixtures or simultaneous multi-part sets.

Precision and Surface Quality Considerations

Most of the time, CNC machining gives better surface finish quality and more accurate measurements than most 3D printing technologies. Modern machining centers can usually get tolerances of less than 0.05 mm and make surfaces rough enough that they can be used in working assemblies without any extra work.

The mechanical cutting action that is part of machining makes sure that the material qualities are the same all the way through the part. This level of uniformity is very important for samples that need to be accurately tested for stress or performance in real-world situations. Depending on the tools used and the conditions of operation, surface finishes can range from simple machined patterns to surfaces that are so smooth they look like mirrors.

The accuracy and surface quality that can be achieved with different 3D printing methods are very different. For smaller parts, high-end SLA systems can get close to the precision of machining, while FDM methods usually need extra work to make the surfaces smooth. Depending on how the part is oriented and the layer thickness settings, the layer lines that are common in additive processes may get in the way of useful testing or judging how it looks.

Material Performance and Selection

It is possible to use all kinds of production materials with CNC machining, such as aerospace-grade aluminum alloys, medical-grade stainless steels, and high-temperature industrial plastics. Because this material can be used in many different ways, prototypes can properly show how the final production part will work in real-world situations.

The properties of the material stay the same as they were in bulk because machining doesn't change the properties of the base material through chemical or thermal processes. This consistency is very important for samples that need to be tested accurately for mechanical issues, thermal issues, or chemical compatibility.

The types of materials that can be used for 3D printing are still limited compared to what can be done with cutting. Newer metal 3D printing technologies have amazing features, but they usually need a lot of work afterward and may have uneven qualities because they are built layer by layer. Polymer options give you a lot of choices for conceptual prototyping, but they might not truly show how the final product will work.

Strategic Decision Criteria for B2B Clients

When B2B procurement professionals choose a prototyping technology, they need to use a thorough framework that takes into account both short-term project needs and long-term strategic goals. This evaluation method makes sure that resources are used in the best way possible and helps reach overall product development goals.

Project Complexity and Volume Assessment

CNC machining is usually best for high-precision tasks that need tight limits and materials that are good enough for production. During the prototype development cycle, machining can work with approved materials and keep dimensions accurate for parts that will be used in medical devices, aerospace structures, or car powertrains.

Complex geometric shapes like internal lattices, organic curves, or multi-part structures may need to be able to be printed. When traditional machining would need multiple sets, a lot of fixturing, or putting together individually machined parts, additive manufacturing works great.

Volume needs have a big effect on the economics of technology choices. The small amount of setup needed for 3D printing makes it a good choice for making prototypes or small batches of design changes. Larger prototype quantities or functional test runs may be able to explain the setup costs of CNC machining by providing better economics per part and consistent quality delivery.

Budget and Timeline Optimization

Instead of just looking at prices for each part, cost analysis needs to look at the whole project's costs. Tooling costs are eliminated by 3D printing, but useful surfaces may need expensive post-processing. CNC machining has higher setup costs but produces final parts that don't need much more work.

Due to time constraints, it is important to carefully review real delivery schedules, taking into account any post-processing needs. While 3D printing can make the first part quickly, removing the supports, finishing the surface, and checking for quality may add time to the total delivery time. CNC machining makes scheduling more reliable because finished parts come straight from the manufacturing processes.

Decision structures are also affected by how to reduce risk. CNC machining gives you reliable material qualities and stable dimensions for important validation tests. 3D printing lets you make quick changes to designs, but it may bring material performance uncertainties that make it harder to understand test results.

Hybrid Strategy Implementation

A lot of great prototyping programs use both technologies together to make the most of their strengths during the development process. 3D printing can be used for quick iterations during early idea validation, while CNC machining is used for accurate material representation and precise dimensioning on final validation prototypes.

This mixed method helps tech teams make the most of their development timelines while keeping costs low. For non-critical parts of complex systems, 3D-printed parts might be used, while machined parts would be used for load-bearing or precision-critical parts.

Geographical factors also support hybrid strategies. For example, local 3D printing resources can help with rapid iteration, while expert machining skills can take care of the final validation needs. This spread-out method cuts down on shipping delays while keeping quality standards high for important test parts.

Trusted Partners in CNC Machining and 3D Printing Services

Choosing qualified prototyping partners is a big decision that has a direct effect on the success of the project, the ability to stick to the schedule, and the general effectiveness of product development. As part of the evaluation process, technical skills, quality methods, and service dependability must be carefully looked at.

Service Provider Evaluation Criteria

Quality approvals are important signs of how well a product is made and how well the process is controlled. Systematic quality management is shown by ISO 9001 certification, while industry-specific certifications, like AS9100 for aircraft or ISO 13485 for medical devices, show that the company has the right kind of knowledge. These certifications make sure that methods are always the same and that everything can be tracked throughout the prototyping process.

The evaluation of technical knowledge should look at both the equipment's capabilities and the engineering support services that are available. Advanced CNC machining centers need to be able to work on multiple axes, have accurate measuring systems, and have a wide range of tools available. For 3D printing businesses to meet the needs of a wide range of projects, they need a number of different technology platforms, material handling systems, and post-processing options.

Portfolio relevance and customer reviews are great ways to find out how much experience a service provider has with applications like yours. Looking at finished projects in related fields can help you figure out how well your skills match up with your prototyping needs. Customer comments on communication, meeting deadlines, and problem-solving skills is an important part of the selection process.

Quote Comparison and Procurement Processes

To effectively compare quotes, you need standard specifications that let you accurately compare costs and capabilities across multiple vendors. Detailed drawings, lists of materials, tolerance standards, and delivery dates make sure that all quotes are based on the same information, which makes comparisons easier.

Online quoting tools make the buying process easier by giving quick feedback on prices and capabilities. Most of the time, these systems have automated design for manufacturability input that finds problems before they happen in production. Digital file upload and instant quotes help people make decisions more quickly while keeping thorough records for tracking projects.

Communication methods and project management skills have a big effect on how well prototyping works. Reliable partners keep you up to date on the project's progress, find problems before they happen, and offer technical help as it's being built. Clear lines of communication make it easy to quickly answer questions about the design or clarifying the specifications that come up during production.

Fudebao Technology's Comprehensive Capabilities

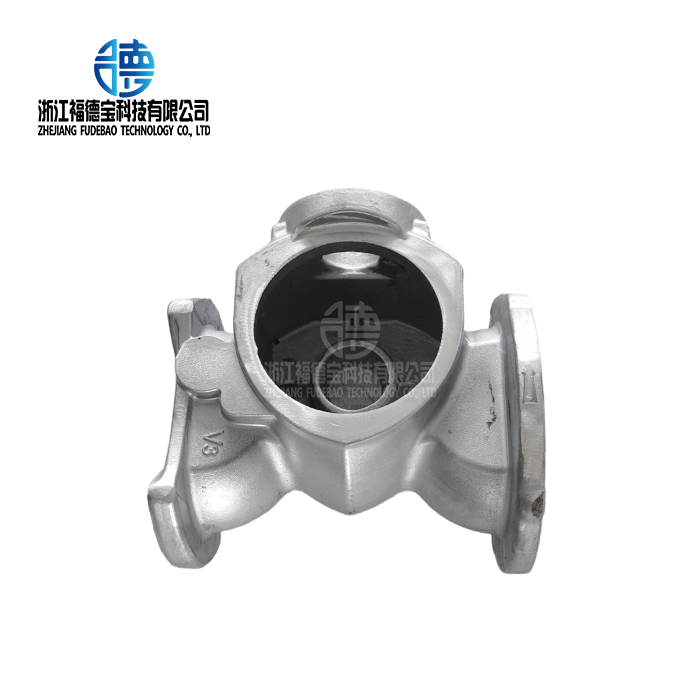

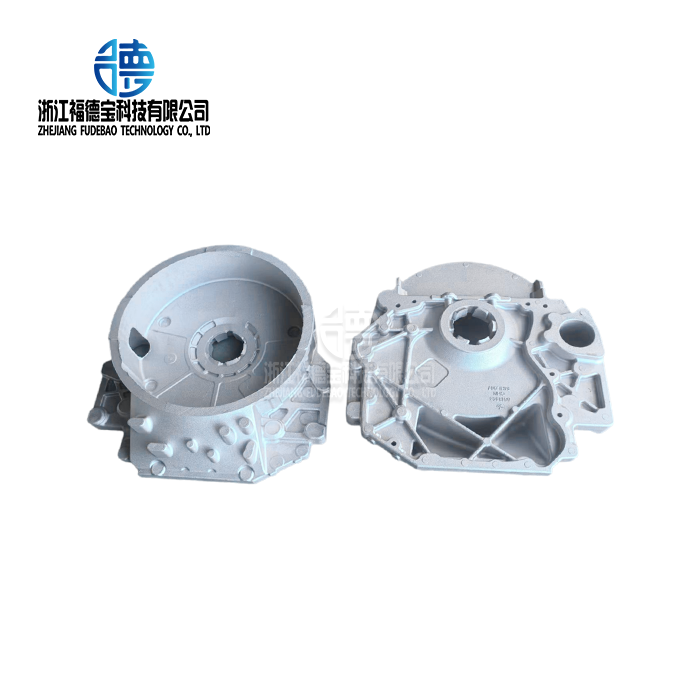

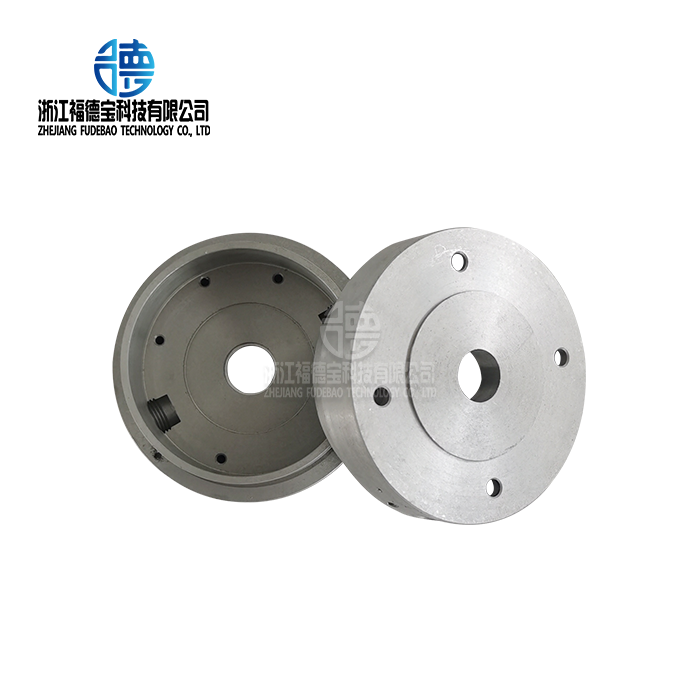

Zhejiang Fudebao Technology Co., Ltd. is a good example of a company that combines advanced machining skills with a wide range of production services that are specifically designed for prototyping needs. Focusing on casting aluminum alloys, copper alloys, and stainless steels, along with precise cutting, gives the company special benefits for making complex prototypes.

The main pieces of equipment at the facility are high-speed machining centers, CNC lathes, low-pressure casting machines, and die-casting systems. These tools help with the whole manufacturing process, from melting the raw materials to delivering the finished parts. This unified method gets rid of the problems that come up when working with multiple sources and makes sure that quality stays the same throughout the production process.

Precision powers of ±0.05mm accuracy meet the strict needs of precision parts for cars, medical equipment housings, and other important uses. "Melting-casting-finishing-surface treatment" is a complete process that allows for one-stop delivery, which makes purchasing easier and cuts down on the wait times and quality risks that come with coordinating with multiple suppliers.

Conclusion

There is no one best way to do rapid prototyping with CNC machining or 3D printing. Instead, the choice relies on the needs of the project, the materials available, and the company's overall goals. CNC machining offers the highest level of accuracy, flexibility in materials, and production-representative properties that are necessary for functional validation and performance testing. 3D printing is great for quickly changing designs, making complicated shapes, and testing ideas early on.

Successful testing strategies often use both technologies in a planned way throughout the development process, making the most of the best parts of each while minimizing the worst parts. The key is to know what the project needs, figure out how much it will cost in total, and choose skilled partners who can provide consistent quality and reliable service.

FAQ

Which technology offers better precision for functional prototypes?

CNC machining consistently delivers superior precision with tolerances routinely achieved within ±0.05mm and excellent surface finish quality. The subtractive manufacturing process maintains consistent material properties throughout the part structure, making it ideal for functional testing and performance validation. While high-end 3D printing technologies can approach machining precision for smaller components, CNC machining remains the preferred choice for applications requiring tight tolerances and production-grade surface quality.

How do lead times compare between CNC machining and 3D printing?

3D printing typically offers faster turnaround for initial prototypes and design iterations due to minimal setup requirements and the ability to produce multiple design variations simultaneously. However, CNC machining often delivers faster completion times for larger or more complex parts, especially when considering post-processing requirements. The choice depends on part complexity, quantity, and required surface finish quality.

What material options are available for each technology?

CNC machining provides access to the complete spectrum of production materials including aerospace-grade aluminum alloys, medical-grade stainless steels, titanium, and engineering plastics. This versatility enables prototypes that accurately represent final production performance. 3D printing material options continue expanding but remain more limited, particularly for metal applications that may require extensive post-processing and exhibit different properties compared to traditionally manufactured materials.

Which approach offers better cost-effectiveness for prototype development?

Cost-effectiveness depends on project volume, complexity, and timeline requirements. 3D printing eliminates tooling costs and offers advantages for single prototypes or small batches requiring rapid iteration. CNC machining involves higher setup costs but provides better per-part economics for larger quantities and delivers finished parts with minimal post-processing requirements. Total project cost analysis should include setup, production, post-processing, and quality verification expenses.

Partner with Fudebao Technology for Advanced CNC Machining Solutions

Partner with a reliable CNC machining company that knows your need for accuracy and time constraints to get the most out of your rapid prototyping. Fudebao Technology has decades of experience in both casting aluminum alloys and making precise machines. They can make prototypes that correctly represent how the production version will work and meet strict quality standards.

Our integrated manufacturing skills get rid of the need for complicated coordination and guarantee consistent quality from the casting process to the final surface treatment. Precision measurement systems and high-speed machining centers are examples of modern tools that can handle tolerances of up to ±0.05mm for important industrial, aerospace, and automotive uses.

Contact our engineering team at hank.shen@fdbcasting.com to discuss your specific prototyping requirements and discover how our comprehensive capabilities can accelerate your product development timeline while maintaining uncompromising quality standards.

References

Gibson, Ian, David Rosen, and Brent Stucker. "Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing." Springer Science & Business Media, 2015.

Kalpakjian, Serope, and Steven Schmid. "Manufacturing Engineering and Technology." Pearson Education, 2019.

Groover, Mikell P. "Fundamentals of Modern Manufacturing: Materials, Processes, and Systems." John Wiley & Sons, 2020.

Wohlers, Terry, and Tim Caffrey. "Wohlers Report 2021: 3D Printing and Additive Manufacturing State of the Industry." Wohlers Associates, 2021.

Singh, Rupinder, and J. Paulo Davim. "Additive Manufacturing: Applications and Innovations." CRC Press, 2018.

Boothroyd, Geoffrey, Peter Dewhurst, and Winston Knight. "Product Design for Manufacture and Assembly." CRC Press, 2010.

YOU MAY LIKE

_1756346144394.webp)

_1756346668222.webp)