Aluminum casting chassis

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:aluminum die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Aluminum Casting Chassis: Precision-Engineered Solutions by Zhejiang Fudebao

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer and supplier of high-quality aluminum casting chassis. With 24 years of expertise in precision casting, we deliver superior products that meet the demanding needs of automotive, industrial, and energy sectors. Our products combine lightweight design with exceptional strength, offering unparalleled performance and durability for your applications.

Product Description

Our products are engineered to perfection, utilizing advanced low-pressure casting techniques. These chassis components provide excellent structural integrity while reducing overall vehicle weight. The result? Enhanced fuel efficiency and improved performance for your automotive or industrial projects.

Parameters

| Parameter | Specification |

|---|---|

| Material | A356 / A380 Aluminum Alloy |

| Tensile Strength | ≥280 MPa |

| Elongation | >5% |

| Wall Thickness | 3-20mm |

| Dimensional Accuracy | ±0.05mm |

| Surface Finish | Ra ≤0.8μm |

| Heat Treatment | T6 |

Applications

- Automotive: Electric vehicle frames, engine mounts, suspension components

- Industrial Equipment: Robotic arm bases, CNC machine frames

- Energy: Battery enclosures for energy storage systems

- Aerospace: Drone bodies, lightweight aircraft components

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, is a pioneer in precision metal casting. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang, houses cutting-edge equipment for comprehensive metal processing. We've earned the trust of global brands like HAAS and ESS, maintaining a stellar 98% on-time delivery rate. Our commitment to innovation is evident in our annual 8% R&D investment, driving us to continuously improve our aluminum casting chassis and other products.

Why Choose Us?

- 24 years of specialized experience in precision casting

- Advanced equipment ensuring ±0.05mm accuracy

- Customization capabilities to meet unique project requirements

- Comprehensive quality control and global certifications

- Cost-effective solutions without compromising on quality

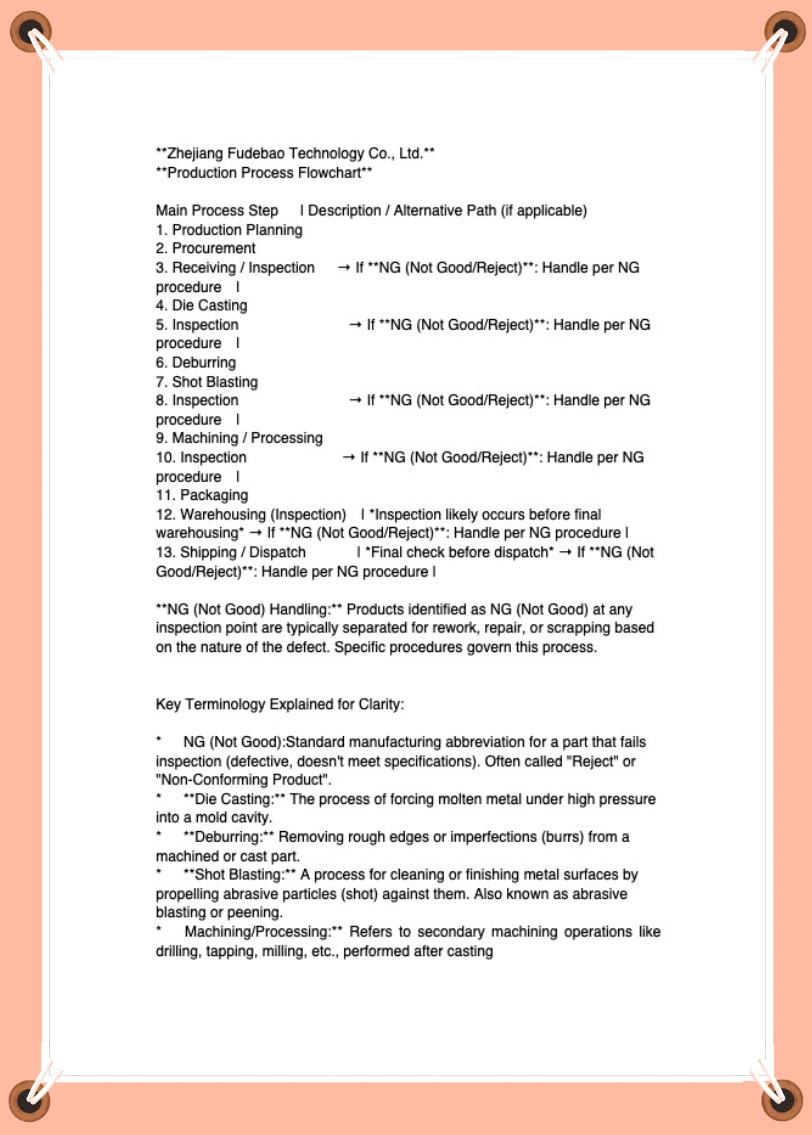

Production Process

- 3D Design & Simulation

- Mold Making

- Low-Pressure Casting

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment

- Final Testing & Packaging

Certificates

- ISO 9001:2015

- IATF 16949

- ISO 14001:2015

- CE Certification

Packaging and Shipping

We ensure secure packaging using custom-designed crates or pallets to protect your products during transit. Our global logistics network guarantees timely delivery to your facility, wherever you are in the world.

FAQ

Q1: What is the minimum order quantity (MOQ) for the products?

A1: Our standard MOQ is 100 units, but we can accommodate smaller orders for prototyping or specific project needs.

Q2: Can you provide custom designs for the products?

A2: Absolutely! We offer full customization services based on your drawings or specifications.

Q3: What is the lead time for a typical order?

A3: Standard lead times range from 3-4 weeks, depending on order complexity and volume.

Q4: Do you offer any warranty on your products?

A4: Yes, we provide a 12-month warranty against manufacturing defects on all our products.

Contact Us

Ready to elevate your projects with our premium aluminum casting chassis? Contact our expert team today!

Email: hank.shen@fdbcasting.com

Experience the Fudebao difference – where precision meets innovation in every chassis we cast!

YOU MAY LIKE

_1756345939856.webp)

_1756346043433.webp)

_1756346144394.webp)

_1756346205762.webp)

_1756346310015.webp)

_1756346421748.webp)

_1756346668222.webp)