cylinder barrel casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:aluminum die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications: automotive, aerospace, electronics, construction, mechanical equipment

Origin: China

Delivery cycle: about two weeks

Certification: ISO9001

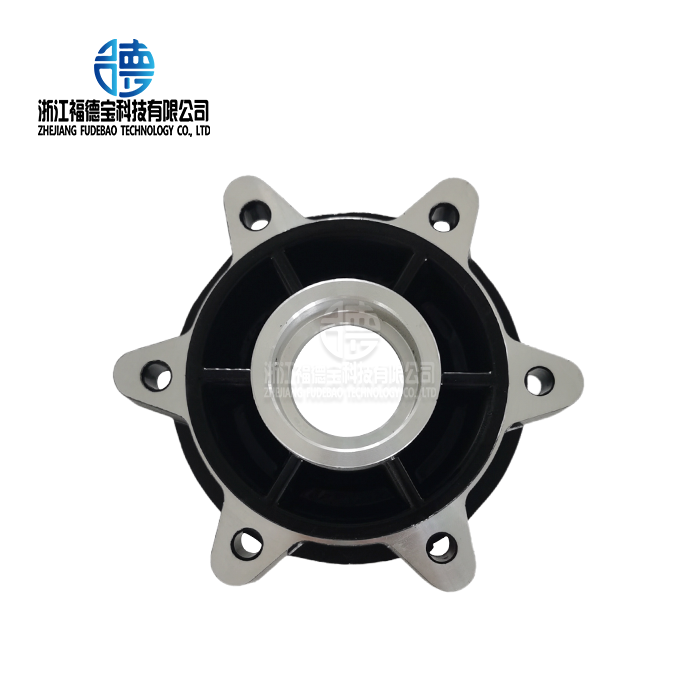

Cylinder Barrel Casting: Precision-Engineered Solutions for High-Performance Engines

Welcome to Zhejiang Fudebao Technology Co., Ltd., your trusted partner for high-quality cylinder barrel casting. With 24 a long time of mastery in exactness casting, we provide predominant items that meet the requesting needs of car, aviation, and mechanical hardware producers. Our progressed fabricating forms and exacting quality control guarantee that each product meets the most noteworthy benchmarks of execution and solidness.

Product Description

Engineers made our product to be very strong, resistant to heat, and accurate in terms of size. We make cylinders that can handle high temperatures and high pressures by using advanced aluminum alloys and cutting-edge casting methods. This make sure that the engine works well and lasts a long time.

Parameters

| Specification | Details |

|---|---|

| Material | High-grade aluminum alloy |

| Casting Method | Low-pressure die casting |

| Tensile Strength | ≥280MPa |

| Dimensional Accuracy | ±0.05mm |

| Surface Finish | Ra ≤0.8μm |

| Heat Treatment | T6 |

| Pressure Resistance | Up to 200 bar |

Product details pictures

Applications

- Automotive engines

- Aircraft engines

- Industrial compressors

- Heavy machinery

- Marine engines

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision casting since 2001. Our 3000㎡ facility in Zhuji, Zhejiang Province, houses cutting-edge equipment and a team of skilled engineers. We specialize in aluminum combination, copper combination, and stainless steel castings, serving worldwide clients with a commitment to advancement and quality. Our items control everything from high-performance cars to progressed mechanical robots, making us a favored accomplice for OEMs around the world.

Why Choose Us?

- Unmatched Expertise: 24 years of experience in precision casting

- Advanced Technology: State-of-the-art equipment for superior quality

- Customization: Tailored solutions to meet your specific requirements

- Quality Assurance: Rigorous testing and ISO 9001 certified processes

- Cost-Effective: Competitive pricing without compromising on quality

Production Process

- Material Selection and Preparation

- Mold Design and Manufacturing

- Low-Pressure Die Casting

- Heat Treatment

- Precision Machining

- Quality Inspection

- Surface Treatment

- Final Testing and Packaging

Certificates

- ISO 9001:2015

- IATF 16949

- AS9100

- CE Certification

Packaging and Shipping

- Custom packaging to ensure product protection

- Global logistics partners for efficient delivery

- Track-and-trace systems for real-time shipment updates

FAQ

Q: What is the minimum order quantity for cylinder barrel castings?

A: We offer flexible order quantities, starting from as low as 5 pieces for sample orders and up to large-scale production runs.

Q: Can you provide custom designs for the products?

A: Absolutely! We offer full customization services based on your specifications and drawings.

Q: What is the lead time for a typical order?

A: Lead times vary depending on the complexity and quantity of the order. Generally, we aim for 3-4 weeks for standard orders.

Q: Do you offer any warranty on your products?

A: Yes, we provide a 12-month warranty on our products against manufacturing defects.

Contact Us

Ready to elevate your engine performance with our premium product? Contact our expert team today for a personalized quote and discover how Zhejiang Fudebao Technology can power your success.

Email: hank.shen@fdbcasting.com

Experience the difference of precision-engineered cylinder barrel casting from Zhejiang Fudebao Technology – where quality meets innovation.

_1756344684491.webp)

_1756345858191.webp)

_1756346205762.webp)

_1756346259673.webp)