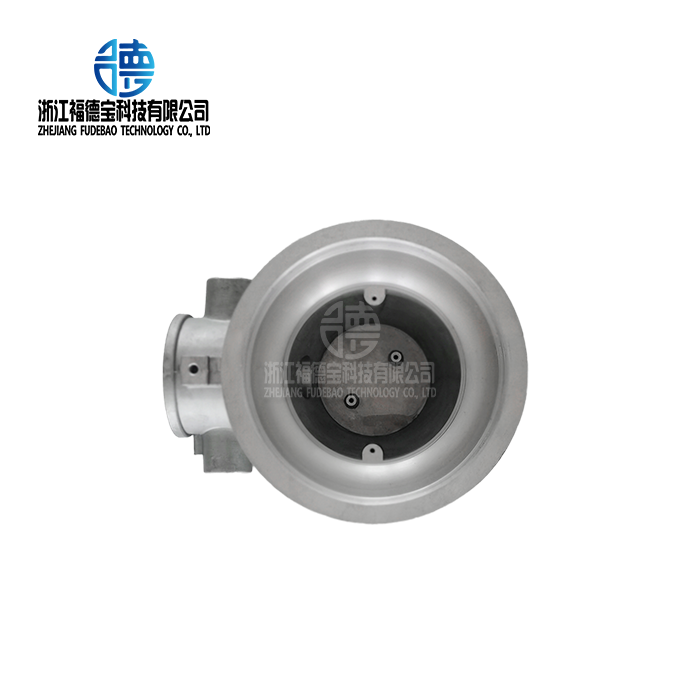

oil pump cover plate

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:aluminum die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

High-Quality Oil Pump Cover Plates: Precision-Engineered for Industrial Excellence

Zhejiang Fudebao Technology Co., Ltd. is your trusted manufacturer and supplier of premium oil pump cover plates. With 24 years of expertise in precision casting, we deliver superior quality products that meet the demanding standards of automotive, industrial machinery, and hydraulic equipment sectors. Our advanced manufacturing processes and rigorous quality control ensure each product offers exceptional durability, precise fitment, and optimal performance for your critical applications.

Product Description

Our oil pump cover plates are engineered to provide reliable sealing and protection for oil pump assemblies in various industrial applications. Crafted from high-grade materials and manufactured to tight tolerances, these cover plates ensure efficient operation and extended service life of your hydraulic systems.

Parameters

| Feature | Specification |

|---|---|

| Material | Aluminum alloy, cast iron, or stainless steel |

| Surface Finish | Ra ≤ 0.8μm |

| Dimensional Tolerance | ±0.05mm |

| Pressure Rating | Up to 350 bar |

| Temperature Range | -40°C to 150°C |

| Corrosion Resistance | Salt spray test >1000 hours |

| Certification | ISO 9001, IATF 16949 |

Product Details Pictures

Applications

- Automotive engines and transmissions

- Industrial hydraulic systems

- Agricultural machinery

- Construction equipment

- Marine propulsion systems

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, is a leading precision casting specialist based in Zhuji, China. Our state-of-the-art 3000㎡ facility houses advanced equipment for comprehensive metal processing, from casting to finishing. We serve global clients across automotive, industrial equipment, and energy sectors, known for our precision, innovation, and commitment to quality. With a focus on continuous improvement and customer satisfaction, we've become a benchmark in China's aluminum foundry industry.

Why Choose Us?

- Precision Manufacturing: Our high-speed machining centers and CNC lathes ensure accuracy up to ±0.05mm.

- Material Expertise: Proficiency in aluminum alloy, copper alloy, and stainless steel casting and machining.

- Quality Assurance: ISO 9001 and IATF 16949 certified processes for consistent, high-quality production.

- Customization Capabilities: Tailored solutions to meet specific industry requirements.

- Cost-Effective: Direct manufacturing and optimized processes for competitive pricing.

- Reliable Delivery: 98% on-time delivery rate and transparent production tracking.

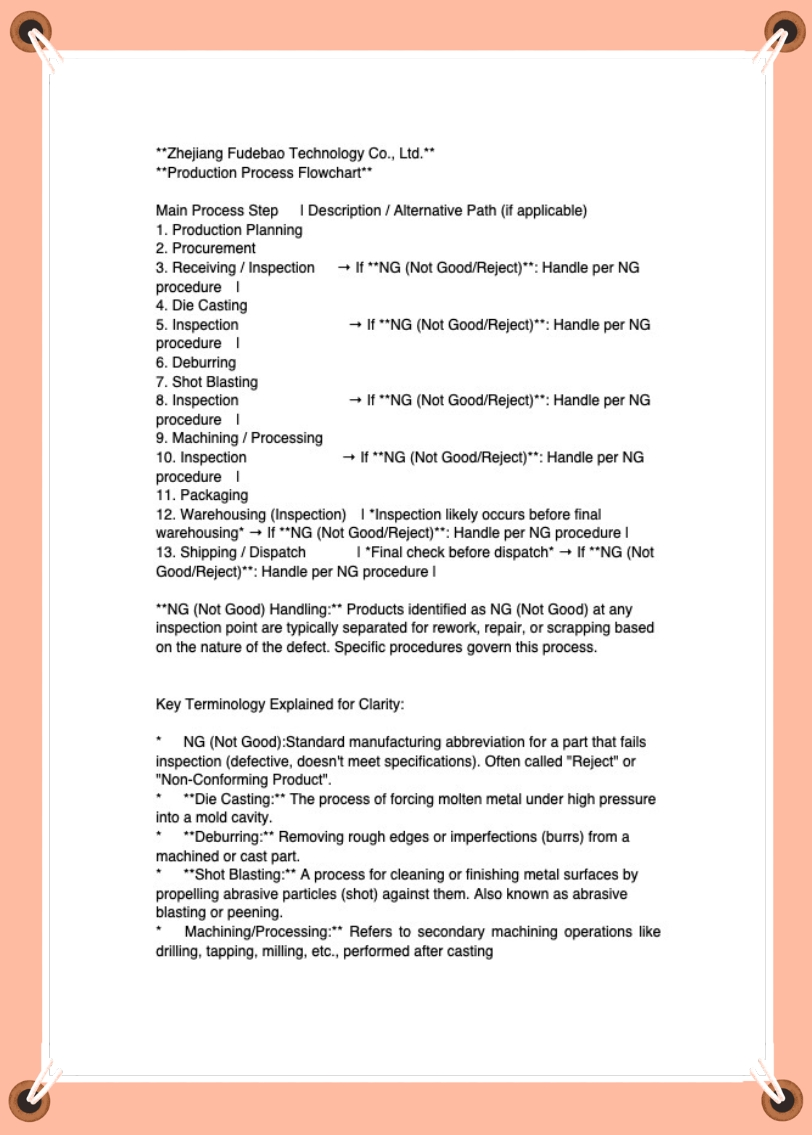

Production Process

- Material Selection

- 3D Modeling and Simulation

- Mold Design and Fabrication

- Casting (Low Pressure or Gravity Die Casting)

- Heat Treatment

- CNC Machining

- Surface Treatment

- Quality Inspection

- Packaging and Shipping

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949:2016 Automotive Quality Management System

- ISO 14001:2015 Environmental Management System

Packaging and Shipping

- Custom protective packaging to prevent damage during transit

- Bulk orders securely palletized for efficient handling

- Worldwide shipping with tracking and insurance options

- Flexible logistics solutions to meet your delivery requirements

FAQ

Q1: What is the minimum order quantity (MOQ) for the products?

A1: Our standard MOQ is 100 units, but we offer flexibility for sample orders and can discuss custom arrangements for larger volumes.

Q2: Can you provide custom designs for the products?

A2: Absolutely! We offer full customization services based on your technical drawings or specifications. Our engineering team can also assist with design optimization.

Q3: What is the lead time for a typical order?

A3: Standard lead times range from 3-4 weeks, depending on quantity and complexity. We also offer expedited production for urgent needs.

Q4: Do you offer material certifications for your products?

A4: Yes, we provide full material traceability and can furnish material certifications (e.g., ASTM, DIN) upon request to meet your quality assurance requirements.

Contact Us

Ready to elevate your hydraulic system performance with our precision-engineered oil pump cover plates? Contact our expert team today for a personalized quote and discover how Zhejiang Fudebao Technology can meet your specific needs.

Email: hank.shen@fdbcasting.com

Let's collaborate to enhance your product quality and operational efficiency with our superior products!

YOU MAY LIKE

_1756344684491.webp)

_1756346043433.webp)

_1756346144394.webp)

_1756346421748.webp)

_1756346570305.webp)