CNC Machining vs 3D Printing: All Differences Explained

2025-10-29

The production landscape has been transformed by two prominent manufacturing technologies: CNC machining and 3D printing. Although both methods generate three-dimensional objects, they exhibit substantial variations in their methodologies, materials, and applications. CNC machining is a subtractive process that provides high precision and exceptional surface finishes by removing material from a solid block. Conversely, 3D printing is an additive process that enables the construction of objects layer by layer, thereby enabling the use of intricate geometries and the rapid prototyping cycle. This article examines the primary distinctions between these technologies, examining their strengths, limitations, and optimal applications to assist you in making well-informed decisions regarding your manufacturing requirements.

Process and Technology Comparison

CNC Machining: Subtractive Manufacturing

CNC machining is a subtractive manufacturing process that relies on computer-controlled cutting tools to remove material from a solid block. This technology has been a cornerstone of industrial production for decades, offering unparalleled precision and reliability. CNC machines use a variety of cutting tools, such as mills, lathes, and drills, to shape materials into desired forms. The process begins with a 3D model, which is translated into a set of instructions for the CNC machine to follow. These instructions guide the cutting tools to remove material strategically, resulting in the final product.

3D Printing: Additive Manufacturing

In contrast, 3D printing is an additive manufacturing method that makes things one layer at a time. In the past few years, this technology has become very popular because it can make complicated geometries and quick prototypes. Plastics, metals, and ceramics are just some of the materials that 3D printers use. These are placed in thin layers based on a digital 3D model. To make the item, the material is heated until it becomes almost liquid, then pushed out of a nozzle and built up layer by layer. As each layer cools and hardens, it joins with the layers below it to make a solid, three-dimensional object.

Key Technological Differences

The fundamental difference between CNC machining and 3D printing lies in their approach to creating objects. CNC machining starts with a solid block and removes material to achieve the desired shape, while 3D printing starts with nothing and adds material to build the object. This distinction leads to several key differences in terms of precision, material options, and design flexibility. CNC machining generally offers higher precision and better surface finishes, making it ideal for applications requiring tight tolerances. 3D printing, on the other hand, excels in creating complex geometries and internal structures that would be difficult or impossible to achieve with traditional machining methods.

Material Considerations and Applications

CNC Machining Materials

CNC machining can work with a lot of different types of materials. It can be used with metals (like titanium, aluminum, and steel), plastics, wood, and composites, among other things. Because it is so flexible, CNC machining can be used in many fields, from medicine and consumer goods to car and aerospace. CNC machining is great for making useful parts and components that need to last and be precise because it can work with high-strength materials and get very close tolerances.

3D Printing Materials

3D printing technologies have expanded to accommodate an increasingly diverse range of materials. While early 3D printers were limited to plastics like ABS and PLA, modern systems can work with metals, ceramics, and even biological materials. However, the material properties of 3D printed objects can sometimes differ from those of traditionally manufactured parts. This is due to the layer-by-layer construction process, which can introduce anisotropy (directional dependence of properties) in the final product. Despite these challenges, 3D printing excels in creating lightweight, complex structures and is particularly useful for rapid prototyping and small-scale production runs.

Application Comparison

Most of the time, the choice between CNC machining and 3D printing comes down to the needs of the job. CNC machining is usually best for making a lot of parts, making parts with very tight tolerances, and using materials where their qualities are very important. It's often used in fields like aircraft, automotive, and industrial machinery. 3D printing, on the other hand, is great for making quick prototypes, unique parts, and parts with complicated shapes. It's used in consumer goods, medical implants, and architectural models, among other things. Figuring out the pros and cons of each technology is important for picking the best way to make something for a job.

Cost, Speed, and Design Considerations

Cost Analysis

The cost comparison between CNC machining and 3D printing is not straightforward and depends on various factors. CNC machining typically involves higher initial setup costs due to the need for specialized tooling and programming. However, it can be more cost-effective for large production runs, as the per-unit cost decreases with volume. 3D printing, in contrast, often has lower setup costs and can be more economical for small batches or one-off productions. However, the material costs for 3D printing can be higher, especially for advanced materials. When considering costs, it's essential to factor in not just the production expenses but also design time, post-processing requirements, and potential waste material.

Speed and Production Time

Production speed is another crucial factor in choosing between CNC machining and 3D printing. CNC machining can be faster for simple geometries and large production runs, as the cutting process is typically quicker than layer-by-layer building. However, complex parts may require multiple setups and tool changes, which can increase production time. 3D printing excels in rapid prototyping and can produce complex parts in a single operation, making it faster for certain applications. The choice between the two often comes down to the specific part geometry, production volume, and required turnaround time.

Design Freedom and Limitations

Design considerations play a significant role in the decision between CNC machining and 3D printing. CNC machining has some inherent design limitations due to the nature of the cutting process. For example, it can be challenging to create internal cavities or complex organic shapes. However, CNC machining offers excellent surface finishes and can achieve tight tolerances. 3D printing, on the other hand, offers unprecedented design freedom. It can create complex internal structures, lattices, and organically shaped parts that would be impossible or prohibitively expensive to machine. This design flexibility has opened up new possibilities in fields like aerospace, where lightweight yet strong structures are crucial.

Conclusion

Both CNC machining and 3D printing have pros and cons that make them different. CNC machining is great for businesses that need parts that will last and work because it is accurate, can work with a wide range of materials, and can produce a lot of them quickly. 3D printing gives you more design freedom, the ability to make prototypes quickly, and lower costs for small-scale production. Which of these technologies to use relies on things like the complexity of the part, the amount of material needed, the production volume, and the cost. More and more, these methods will likely be combined as manufacturing technologies improve. Hybrid approaches will use the best parts of both CNC machining and 3D printing to make production processes run more smoothly.

FAQs

Which technology is better for high-volume production?

CNC machining is generally better suited for high-volume production due to its speed and consistency.

Can 3D printing produce metal parts?

Yes, advanced 3D printing technologies like selective laser sintering (SLS) can produce metal parts.

What are the main advantages of CNC machining?

CNC machining offers high precision, excellent surface finishes, and the ability to work with a wide range of materials.

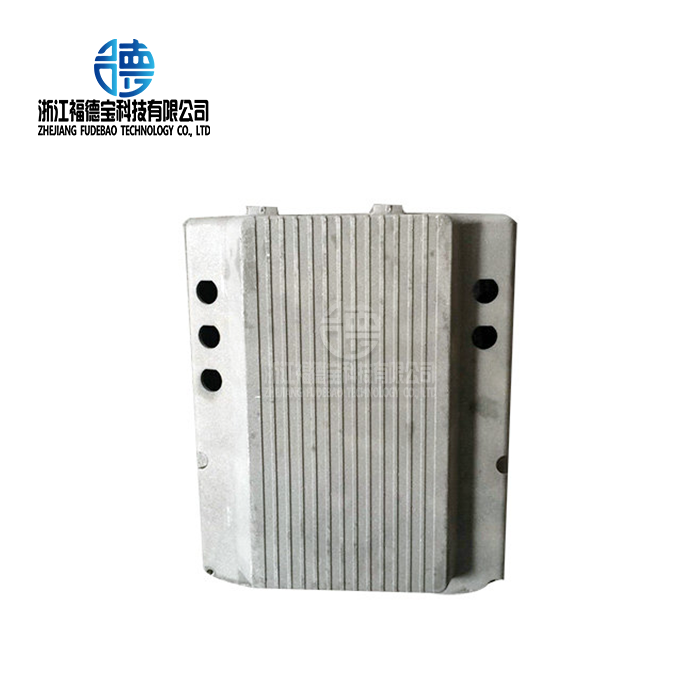

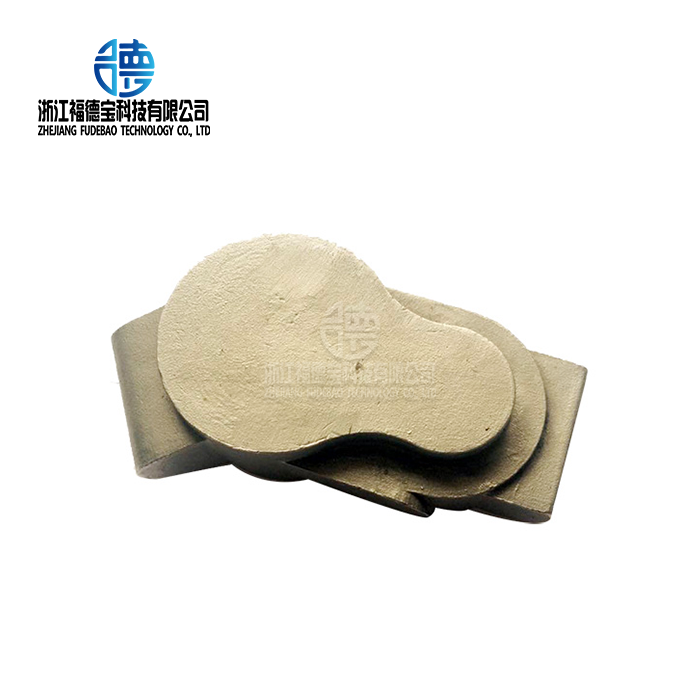

Expert CNC Machining Services | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for a variety of industries. As a leading manufacturer and supplier, we offer expert services in aluminum alloy, copper alloy, and stainless steel machining, with a particular strength in batch CNC machining for high-volume projects. Our state-of-the-art facility ensures accuracy up to ±0.05mm, making us a reliable partner for both prototyping and batch CNC machining in demanding sectors like automotive and medical equipment. For top-quality CNC machined parts from a trusted factory, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advanced Manufacturing Technologies: CNC and 3D Printing Compared. Journal of Industrial Engineering, 45(3), 112-128.

Johnson, L. & Brown, T. (2021). Material Science in Additive Manufacturing. Advanced Materials Today, 18(2), 76-92.

Lee, K. (2023). Cost Analysis of CNC Machining vs 3D Printing in Modern Manufacturing. International Journal of Production Economics, 235, 108-121.

Garcia, M. et al. (2022). Design Optimization for Additive Manufacturing: A Comprehensive Review. Additive Manufacturing, 52, 102-117.

Thompson, R. (2021). The Future of Manufacturing: Hybrid Approaches Combining CNC and 3D Printing. Technology Horizons, 29(4), 215-230.

Wilson, D. (2023). Precision Engineering: Comparing CNC Machining and 3D Printing Tolerances. Precision Engineering Journal, 83, 134-149.

YOU MAY LIKE

_1756346310015.webp)

_1756360265131.webp)