Aluminum castings Crane bracket

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:aluminum die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

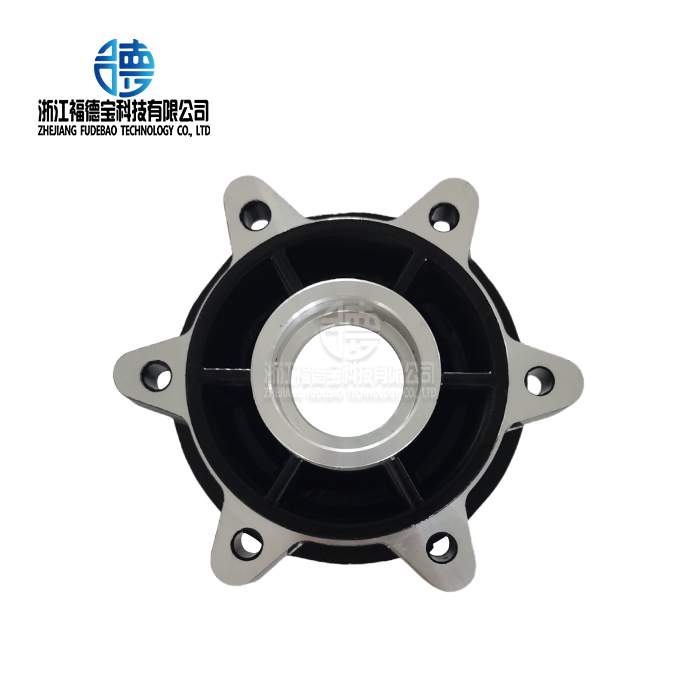

Aluminum Castings Crane Bracket: Durable, Precision-Engineered Solutions

At Zhejiang Fudebao Technology Co., Ltd., we specialize in manufacturing high-quality aluminum castings crane brackets. Our 24 years of experience in precision casting means that our products are stronger, last longer, and be more reliable. We can make solutions just for you that meet the strict needs of the construction and heavy machinery businesses.

Product Description

Our products are built to last in harsh conditions and with heavy loads. Using modern low-pressure casting methods, these brackets are made to be strong while also being light. They're great for many crane uses because they keep the load stable and safe while it's being lifted.

Parameters

| Parameter | Specification |

|---|---|

| Material | Aluminum Alloy (A356, A357) |

| Tensile Strength | ≥280 MPa |

| Yield Strength | ≥210 MPa |

| Elongation | >5% |

| Surface Finish | Ra ≤3.2μm |

| Weight Reduction | Up to 15% compared to steel |

| Corrosion Resistance | Excellent |

| Heat Treatment | T6 |

| Dimensional Tolerance | ±0.05mm |

Applications

- Construction cranes

- Port and shipyard cranes

- Industrial overhead cranes

- Mobile cranes

- Telescopic handlers

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision metal casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses advanced equipment for the entire production process. We serve global industries including automotive, industrial equipment, and energy sectors. Our commitment to innovation is reflected in our annual 8% R&D investment and multiple patents.

Why Choose Us?

- Expertise: 24 years of specialized experience in aluminum castings

- Quality: ISO 9001 certified with stringent quality control measures

- Customization: Tailored solutions to meet specific requirements

- Cost-effective: Competitive pricing for both small and large orders

- Fast Delivery: Efficient production and logistics management

- Technical Support: Comprehensive engineering and design assistance

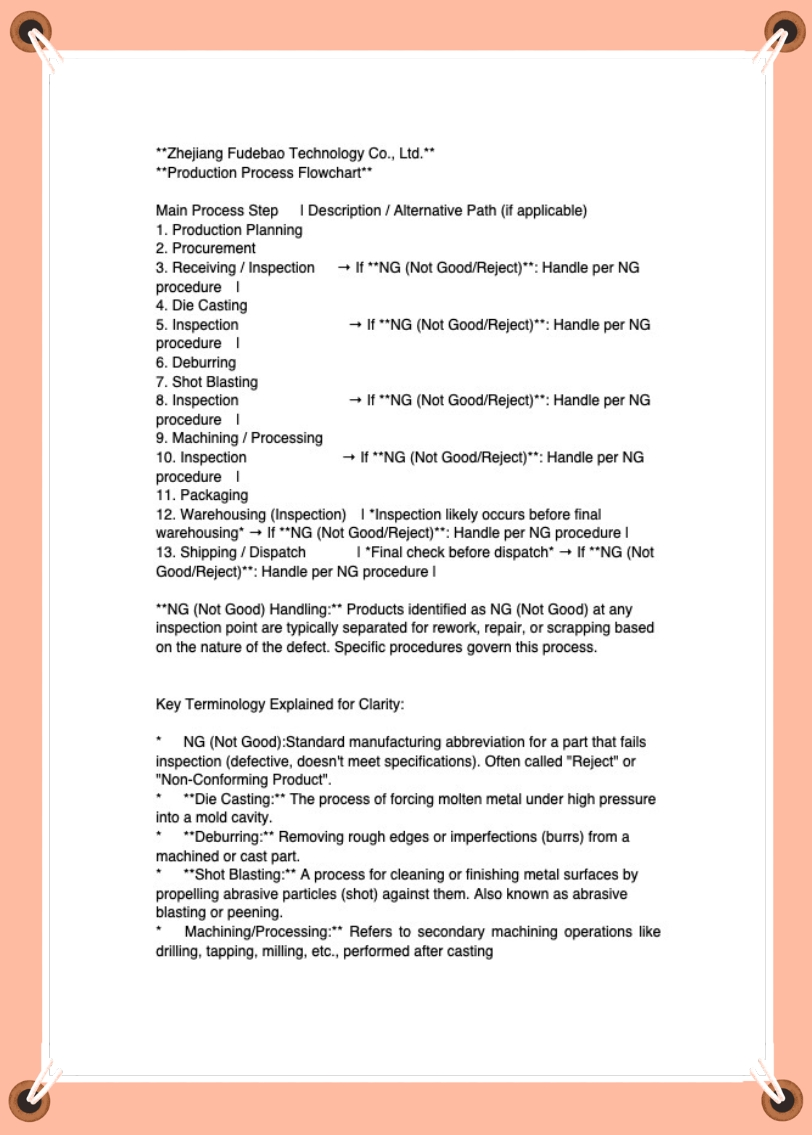

Production Process

- 3D Design and Simulation

- Mold Making

- Low-Pressure Casting

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment

- Final Testing and Packaging

Certificates

- ISO 9001:2015

- CE Certification

- RoHS Compliance

- ASTM Standards

Packaging and Shipping

We ensure secure packaging to protect your aluminum castings crane brackets during transit. Our logistics team arranges efficient shipping worldwide, with options for air, sea, or land transportation based on your needs and timeline.

FAQ

Q1: What is the minimum order quantity for the products?

A1: We offer flexible order quantities, starting from as low as 5 pieces for customized orders.

Q2: Can you provide samples before bulk production?

A2: Yes, we can provide sample brackets for testing and approval before proceeding with large-scale production.

Q3: What is the lead time for the products?

A3: Typical lead time is 3-4 weeks, depending on order quantity and complexity. We can discuss rush orders if needed.

Q4: Do you offer design assistance for custom crane brackets?

A4: Absolutely. Our engineering team can help optimize your designs for improved performance and cost-efficiency.

Contact Us

Ready to elevate your crane performance with our products? Contact us today for a free consultation and quote.

Email: hank.shen@fdbcasting.com

Trust Zhejiang Fudebao Technology Co., Ltd. for precision-engineered aluminum castings crane brackets that combine strength, durability, and innovation. Let's build a stronger future together!

_1756346310015.webp)

_1756345939856.webp)

_1756345858191.webp)

_1756346570305.webp)