The Fundamentals of Low Pressure Casting

Equipment and Setup

Low pressure casting relies on specialized equipment designed to achieve precise and consistent results. The setup typically includes a pressurized furnace, a riser tube, and a reusable mold. The furnace holds the molten metal at an optimal temperature, ensuring proper fluidity for casting. The riser tube serves as a controlled conduit between the furnace and the mold, regulating metal flow. Molds, often constructed from steel or other high-temperature resistant materials, define the shape of the final component while withstanding repeated thermal cycles without deformation.

Material Selection

Low pressure casting is compatible with a variety of metals but is particularly effective with aluminum alloys. The process allows for the production of components with minimal porosity, smooth surface finishes, and excellent mechanical properties, making it ideal for lightweight yet strong parts. Additionally, low pressure casting can accommodate magnesium alloys, copper alloys, and selected grades of iron. Choosing the appropriate material depends on the desired balance of strength, weight, corrosion resistance, and thermal performance for the intended application.

Process Parameters

Achieving high-quality castings in low pressure casting depends on precise control of process parameters. Key factors include the temperature of the molten metal, mold temperature, metal fill rate, and applied pressure. Fine-tuning these variables ensures optimal mold filling, minimizes defects, and adapts the process to complex geometries or varying material properties. Advanced monitoring systems, computer-controlled furnaces, and automated pressure regulation help maintain consistency, allowing manufacturers to produce uniform components across multiple production runs with minimal variation.

The Low Pressure Casting Process: Step by Step

Preparation Phase

The process begins with thorough preparation. The mold is cleaned, preheated, and coated with a release agent to facilitate easy part removal. Meanwhile, the metal is melted and degassed in the furnace to remove impurities and trapped gases that could compromise the final product's integrity.

Filling and Solidification

Once preparations are complete, the low pressure casting process commences. Pressurized inert gas forces the molten metal up the riser tube and into the mold cavity. The low pressure ensures a gentle, controlled fill that minimizes turbulence and air entrapment. As the metal enters the mold, it begins to solidify from the outermost surfaces inward. The continued application of pressure during solidification helps compensate for shrinkage, resulting in denser, higher-quality castings.

Cooling and Ejection

After the part has solidified, the pressure is released, and any excess metal flows back into the furnace. The mold is then opened, and the cast part is ejected. Depending on the complexity of the part and the mold design, this process may involve the use of ejector pins or other removal mechanisms. The part then undergoes cooling, either naturally or through controlled means, to achieve the desired microstructure and properties.

Advantages and Applications of Low Pressure Casting

Benefits Over Traditional Methods

Low pressure casting offers several advantages over conventional casting techniques. It produces parts with higher density, improved mechanical properties, and better dimensional accuracy. The process also minimizes material waste, as excess metal can be reused. Additionally, the controlled fill and solidification reduce the occurrence of defects such as porosity and shrinkage, leading to higher overall quality and reduced scrap rates.

Industry Applications

The automotive industry is a major beneficiary of low pressure casting technology. Engine blocks, cylinder heads, and wheel rims are just a few examples of components frequently produced using this method. In aerospace, low pressure casting is employed to create complex structural parts that require high strength-to-weight ratios. The process also finds applications in the production of industrial machinery components, pump housings, and even artistic sculptures where intricate details are crucial.

Future Developments

As technology advances, low pressure casting continues to evolve. Innovations in mold design, real-time process monitoring, and automation are pushing the boundaries of what's possible with this technique. Research into new alloy formulations specifically tailored for low pressure casting promises to expand its applications even further. Additionally, the integration of simulation software and artificial intelligence is helping optimize process parameters and predict part quality with unprecedented accuracy.

Conclusion

Low pressure casting stands out as a versatile and efficient method for producing high-quality metal components. Its ability to create complex shapes with excellent mechanical properties makes it invaluable across various industries. As manufacturers increasingly seek ways to improve product quality while reducing costs and environmental impact, low pressure casting is likely to play an even more significant role in the future of metal forming processes. By understanding its principles and capabilities, engineers and designers can leverage this technology to create innovative solutions for tomorrow's challenges.

FAQs

What are the main advantages of low pressure casting?

Low pressure casting offers benefits such as improved part density, better mechanical properties, reduced defects, and the ability to create complex geometries with thin walls.

Which industries commonly use low pressure casting?

The automotive, aerospace, and industrial machinery sectors frequently utilize low pressure casting for producing high-quality components.

Can low pressure casting work with all types of metals?

While it's particularly well-suited for aluminum alloys, low pressure casting can also be used with other metals like magnesium and copper alloys, and some grades of iron.

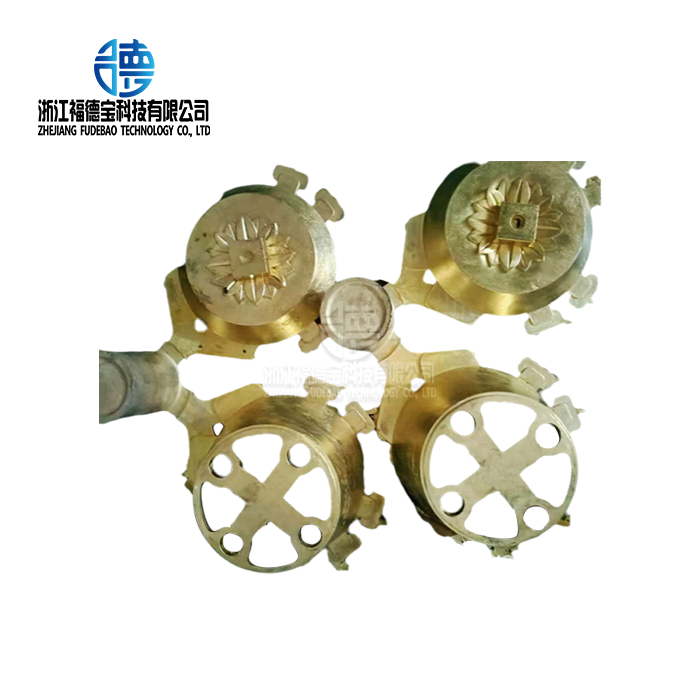

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in advanced low pressure casting techniques to deliver superior metal components. Our state-of-the-art facilities and experienced team ensure precision and quality in every project. As a leading manufacturer and supplier, we offer customized solutions for diverse industries. Contact us at hank.shen@fdbcasting.com to discuss how our low pressure casting expertise can elevate your products.

References

Smith, J. (2022). Advances in Low Pressure Casting Technology. Journal of Metallurgical Engineering, 45(3), 178-195.

Zhang, L., & Chen, X. (2021). Optimizing Process Parameters in Low Pressure Casting: A Comprehensive Review. Materials Today: Proceedings, 15, 245-260.

Brown, A. (2023). Low Pressure Casting in Automotive Manufacturing: Current Trends and Future Prospects. International Journal of Automotive Engineering, 12(2), 89-104.

Taylor, R., & Johnson, M. (2022). Comparative Analysis of Casting Techniques: Low Pressure vs. Gravity Die Casting. Materials Science and Engineering: A, 825, 141864.

Lee, S., & Park, H. (2021). Microstructure Evolution in Low Pressure Cast Aluminum Alloys. Acta Materialia, 209, 116808.

Wilson, D. (2023). Sustainability in Metal Casting: The Role of Low Pressure Techniques. Journal of Cleaner Production, 350, 131456.

_1756349071334.webp)

_1756349794241.webp)

_1756352340434.webp)

_1756352561845.webp)