New energy motor shell aluminum casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

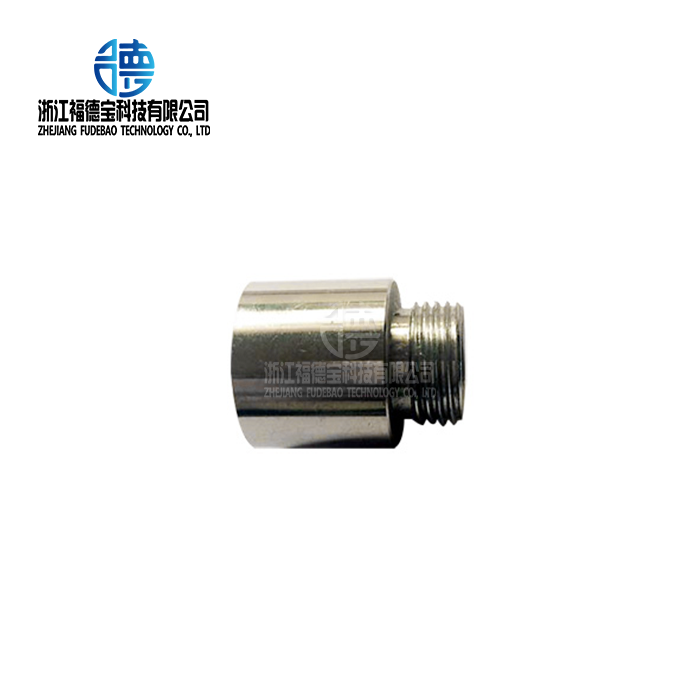

New Energy Motor Shell Aluminum Casting: Powering the Future of Electric Mobility

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer and supplier of high-quality New energy motor shell aluminum castings. With 24 years of precision casting expertise, we deliver innovative solutions for the electric vehicle and renewable energy sectors. Our advanced manufacturing processes and strict quality control ensure superior performance, lightweight design, and cost-effectiveness for your EV motor housing needs.

Product Description

Our New energy motor shell aluminum castings are engineered to meet the demanding requirements of modern electric powertrains. These precision-crafted components offer excellent thermal management, structural integrity, and weight reduction – crucial factors in maximizing EV efficiency and range.

Parameters

| Parameter | Specification |

|---|---|

| Material | A356 / ADC12 Aluminum Alloy |

| Casting Process | Low Pressure Die Casting |

| Wall Thickness | 3-8 mm |

| Weight | 2-15 kg (customizable) |

| Dimensional Tolerance | ±0.05 mm |

| Surface Finish | Ra ≤ 1.6 μm |

| Heat Treatment | T6 |

| Corrosion Resistance | Salt Spray Test >1000 hours |

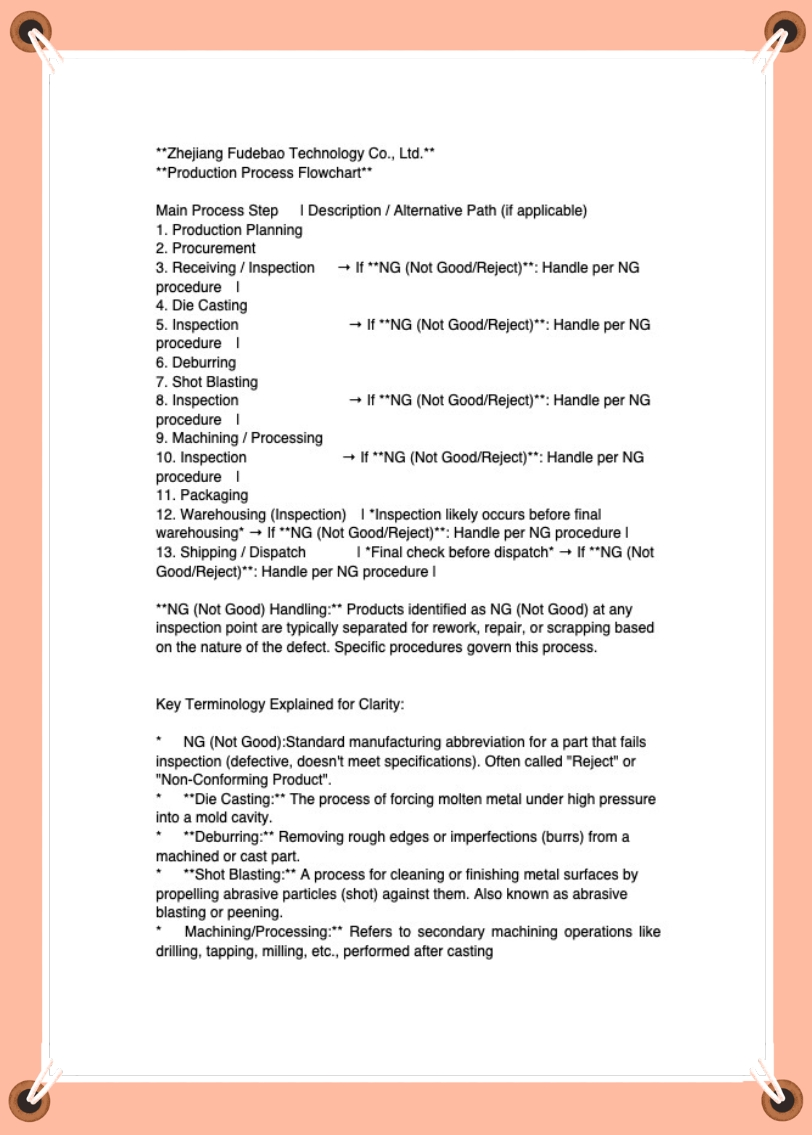

Product Details Pictures

Applications

- Electric vehicle traction motors

- Hybrid vehicle powertrains

- Industrial electric motors

- Wind turbine generators

- Energy storage systems

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, is a leading precision casting specialist based in Zhuji, China. Our 3000㎡ state-of-the-art facility houses advanced equipment for the entire production process, from melting to surface treatment. We serve global automotive, industrial, and energy sectors with our expertise in aluminum, copper, and stainless steel castings. Our commitment to innovation, quality, and customer satisfaction has made us a trusted partner for industry leaders worldwide.

Why Choose Us?

- 24 years of specialized experience in precision casting

- Advanced manufacturing capabilities with ±0.05mm accuracy

- Comprehensive quality management system (IATF 16949 certified)

- Flexible production for both small batches and high-volume orders

- In-house R&D team for continuous product improvement

- Global supply chain experience with on-time delivery

Production Process

- Design optimization and DFM analysis

- Tooling development and prototyping

- Low pressure die casting

- Heat treatment and age hardening

- CNC machining for precise tolerances

- Quality inspection (CMM, X-ray, etc.)

- Surface treatment (if required)

- Final inspection and packaging

Certificates

- IATF 16949:2016

- ISO 9001:2015

- ISO 14001:2015

- CE Certification

Packaging and Shipping

- Custom-designed packaging to ensure product protection

- Wooden crates or pallets for bulk orders

- Express shipping available for urgent orders

- Full traceability with barcoding system

FAQ

Q1: What is the minimum order quantity (MOQ) for the product?

A1: Our standard MOQ is 100 pieces. However, we offer flexibility for smaller trial orders to ensure the product meets your specifications.

Q2: Can you provide samples before bulk production?

A2: Yes, we offer prototype samples for testing and approval. This helps ensure the final product meets your exact requirements.

Q3: What is the lead time for a typical order?

A3: Lead time varies based on order quantity and complexity. Generally, it ranges from 4-6 weeks after design approval. We can provide a more accurate timeline upon receiving your specific requirements.

Q4: Do you offer any customization options for the motor shells?

A4: Absolutely! We specialize in customized solutions. Our engineering team can work with you to optimize the design for performance, weight reduction, or cost-efficiency based on your unique needs.

Contact Us

Ready to elevate your EV motor performance with our premium New energy motor shell aluminum castings? Contact our expert team today for a consultation and quote.

Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology power your next-generation electric mobility solutions with precision-engineered aluminum castings!

YOU MAY LIKE

_1756352561845.webp)

_1756352822273.webp)