Optimizing Mold Design and Material Selection

Advanced Mold Design Techniques

Implementing advanced mold design techniques is crucial for enhancing the efficiency of low pressure casting. Computer-aided design (CAD) and simulation software play a pivotal role in this process. These tools allow engineers to create and test mold designs virtually, identifying potential issues before physical production begins. By simulating the casting process, factors such as metal flow, solidification rates, and potential defects can be analyzed and addressed proactively.

Moreover, optimizing the gating system design is essential. A well-designed gating system ensures smooth and controlled metal flow into the mold cavity, reducing turbulence and minimizing the risk of defects. This can lead to fewer rejected parts and improved overall quality. Additionally, incorporating proper venting in the mold design helps in the escape of trapped gases, further enhancing the quality of the final product.

Material Selection for Molds

Choosing the right material for mold construction is equally important in improving efficiency. Materials with high thermal conductivity, such as H13 tool steel or copper alloys, can enhance heat transfer during the casting process. This results in faster cooling rates and shorter cycle times, directly impacting production efficiency.

Furthermore, considering the durability and lifespan of mold materials is crucial. While some materials might have a higher upfront cost, their longevity and ability to maintain dimensional accuracy over numerous casting cycles can lead to significant long-term savings and improved efficiency.

Thermal Management in Mold Design

Effective thermal management within the mold is a key factor in optimizing low pressure casting efficiency. Incorporating cooling channels strategically in the mold design can help control the solidification process more precisely. This not only improves the quality of the cast parts but also reduces cycle times.

Advanced techniques like conformal cooling, where cooling channels follow the contours of the part, can provide more uniform cooling. This results in reduced internal stresses in the cast parts, fewer defects, and potentially faster production rates. By carefully balancing the heating and cooling aspects of the mold, manufacturers can achieve optimal solidification patterns, leading to higher quality parts and improved overall efficiency in the low pressure casting process.

Enhancing Process Control and Automation

Advanced Monitoring Systems

Implementing advanced monitoring systems is crucial for maintaining consistent quality and efficiency in low pressure casting. Real-time monitoring of key parameters such as temperature, pressure, and flow rates allows for immediate adjustments to the process. Sensors and data logging systems can track these variables throughout the casting cycle, providing valuable insights for process optimization.

Furthermore, integrating artificial intelligence (AI) and machine learning algorithms into the monitoring systems can lead to predictive maintenance and quality control. These systems can analyze patterns in the data to predict potential issues before they occur, allowing for proactive maintenance and reducing unplanned downtime. This predictive approach not only improves efficiency but also helps in maintaining consistent product quality.

Automation in Material Handling

Automating material handling processes can significantly enhance efficiency in low pressure casting production. Robotic systems for loading and unloading molds, transferring parts, and handling raw materials can reduce labor costs and increase production speed. These automated systems can work continuously with high precision, minimizing human error and improving safety in the workplace.

Additionally, implementing automated conveyor systems and smart storage solutions can streamline the flow of materials and finished products through the production line. This reduces bottlenecks and ensures a smooth, continuous production process. Automated guided vehicles (AGVs) can be employed for transporting materials and parts between different stages of production, further enhancing efficiency and reducing manual handling.

Process Parameter Optimization

Optimizing process parameters is key to achieving maximum efficiency in low pressure casting. This involves fine-tuning variables such as metal temperature, injection pressure, and cooling rates. Utilizing design of experiments (DOE) methodologies can help in systematically identifying the optimal combination of these parameters for different part geometries and materials.

Moreover, implementing adaptive control systems can allow for real-time adjustments of process parameters based on feedback from monitoring systems. This dynamic approach ensures that the casting process remains at peak efficiency despite variations in environmental conditions or slight changes in raw material properties. By continuously optimizing these parameters, manufacturers can achieve consistent quality, reduced scrap rates, and improved overall production efficiency in their low pressure casting operations.

Quality Control and Continuous Improvement

Advanced Inspection Techniques

Implementing advanced inspection techniques is crucial for maintaining high quality standards in low pressure casting production. Non-destructive testing (NDT) methods such as X-ray inspection, ultrasonic testing, and computed tomography (CT) scanning can detect internal defects without damaging the parts. These techniques allow for thorough quality checks without sacrificing production volume.

Furthermore, in-line inspection systems can be integrated into the production line to perform real-time quality checks. This might include automated visual inspection systems using high-resolution cameras and image processing software to detect surface defects. By identifying and addressing quality issues early in the production process, manufacturers can reduce waste and improve overall efficiency.

Data Analytics for Process Improvement

Leveraging data analytics can provide valuable insights for continuous improvement in low pressure casting. By collecting and analyzing data from various stages of the production process, manufacturers can identify trends, patterns, and potential areas for improvement. This data-driven approach allows for more informed decision-making and targeted process enhancements.

Statistical process control (SPC) techniques can be applied to monitor and control the variability in the casting process. By tracking key performance indicators (KPIs) and analyzing process capability indices, manufacturers can ensure that their production remains within specified limits and identify opportunities for optimization. This continuous monitoring and analysis cycle leads to incremental improvements in efficiency over time.

Employee Training and Engagement

Investing in comprehensive employee training programs is essential for improving efficiency in low pressure casting production. Well-trained operators and technicians can better understand the intricacies of the process, make informed decisions, and troubleshoot issues effectively. Regular training sessions on new technologies, best practices, and safety procedures ensure that the workforce remains up-to-date and capable of handling the demands of modern casting operations.

Moreover, fostering a culture of continuous improvement among employees can lead to valuable insights and innovations. Implementing suggestion systems and quality circles encourages employees to contribute ideas for process improvements. This not only enhances efficiency but also boosts employee engagement and job satisfaction. By tapping into the collective knowledge and experience of the workforce, manufacturers can uncover practical solutions to efficiency challenges and drive ongoing improvements in their low pressure casting operations.

Conclusion

Improving efficiency in low pressure casting production is a multifaceted endeavor that requires a comprehensive approach. By optimizing mold design and material selection, enhancing process control and automation, and focusing on quality control and continuous improvement, manufacturers can significantly boost their productivity and product quality. The integration of advanced technologies, from AI-driven monitoring systems to automated material handling, plays a crucial role in this optimization process. Moreover, the importance of employee training and engagement cannot be overstated, as it fosters a culture of innovation and continuous improvement. As the industry evolves, staying abreast of these advancements and consistently implementing best practices will be key to maintaining a competitive edge in low pressure casting production.

FAQs

What are the key benefits of improving efficiency in low pressure casting?

Improved efficiency leads to higher productivity, reduced costs, better quality products, and increased competitiveness in the market.

How does automation contribute to efficiency in low pressure casting?

Automation reduces human error, increases production speed, ensures consistent quality, and allows for continuous operation, significantly boosting overall efficiency.

What role does material selection play in low pressure casting efficiency?

Proper material selection for molds and cast parts affects cooling rates, cycle times, and product quality, directly impacting production efficiency.

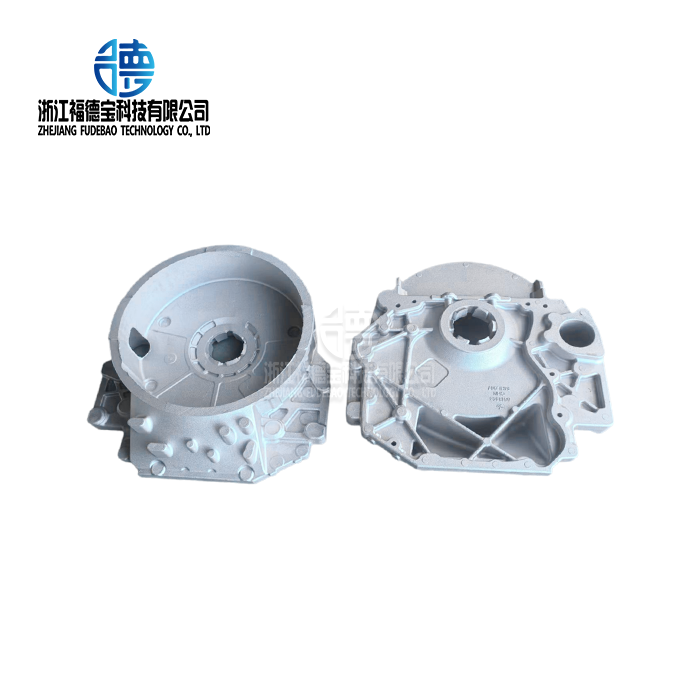

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing cutting-edge low pressure casting solutions tailored to your specific needs. Our state-of-the-art facilities and expert team ensure high-quality, efficient production of aluminum alloy, copper alloy, and stainless steel components. As a leading low pressure casting manufacturer and supplier, we offer comprehensive services from design to finished products. Contact us at hank.shen@fdbcasting.com to discover how we can enhance your production efficiency and quality.

References

Smith, J. (2022). Advancements in Low Pressure Casting Technologies. Journal of Metallurgical Engineering, 45(3), 112-128.

Johnson, R., & Thompson, L. (2021). Optimizing Mold Design for Efficient Low Pressure Casting. International Journal of Foundry Research, 33(2), 67-82.

Lee, S., et al. (2023). Automation and Process Control in Modern Casting Operations. Advanced Manufacturing Technology, 18(4), 201-215.

Brown, A. (2022). Quality Control Strategies in Metal Casting: A Comprehensive Review. Materials Processing and Quality Assurance, 29(1), 34-49.

Garcia, M., & Rodriguez, P. (2021). The Role of Data Analytics in Improving Casting Efficiency. Smart Manufacturing Systems, 12(3), 156-170.

Wilson, T. (2023). Employee Training and Engagement in High-Tech Manufacturing Environments. Journal of Industrial Management, 40(2), 89-103.

_1756346259673.webp)

_1756350092126.webp)