Lightweight structure frames, precise engine housings, battery casings, and motor components are some of the best aluminum die casting parts for cars and electric cars. When makers use high pressure die casting technology, they can make complicated shapes with very accurate measurements and great surface finishing. OEMs need these lightweight metal parts to be strong and last a long time. They also have to meet strict casting tolerance standards that are necessary for current car performance.

Why Aluminum Die Casting Dominates Automotive Manufacturing?

Modern manufacturing techniques that balance reducing weight with maintaining structure stability are very important for making cars and electric vehicles. It has become clear that the aluminum die casting process is the best way to make complicated car parts that can't be made easily with other methods.

Electric car makers have to deal with special problems when it comes to distributing weight and keeping temperatures down. Components made of aluminum metal are very good at getting rid of heat while still being light, which is important for extending battery range. With the high pressure die casting method, it is possible to make cooling tubes and fixing points that are very complicated and would need more than one step of assembly with other materials.

Precision die cast aluminum parts are also very helpful for traditional internal combustion engines. Pressure die casting machines are used to make engine blocks, transmission housings, and structural parts. They produce high-volume production runs with uniform quality and physical stability.

Selection Criteria for Premium Automotive Die Cast Components

To find the best aluminum die casting parts, you have to look at a lot of technical and practical factors that have a direct effect on how well the car works and how efficiently the parts are made.

The qualities of the material are what determine which parts to use. The makeup of the aluminum metal needs to have enough tensile strength while also being very resistant to rust and good at conducting heat. Advanced metal formulations make these properties work best for certain car uses, like parts of the engine bay that are exposed to high temperatures or frame parts that need to be as stiff as possible.

Precision in manufacturing has a direct effect on how well parts work together and how reliable they are. The design of a die casting mold has to be able to handle complicated shapes while still meeting the tight accuracy standards for casting. Premium makers use metal flow modeling technology to make sure that the quality of each production batch is the same by adjusting the filling speed and reducing the number of holes in the die.

Professional-grade parts are different from normal industrial products because of their surface quality and ability to be finished. Better surface finishing cuts down on the need for post-processing and lets the part be directly installed in areas that can be seen on the car. CNC cutting gives you the accuracy you need for important fixing areas and threaded connections.

Top Aluminum Die Casting Components for Automotive Applications

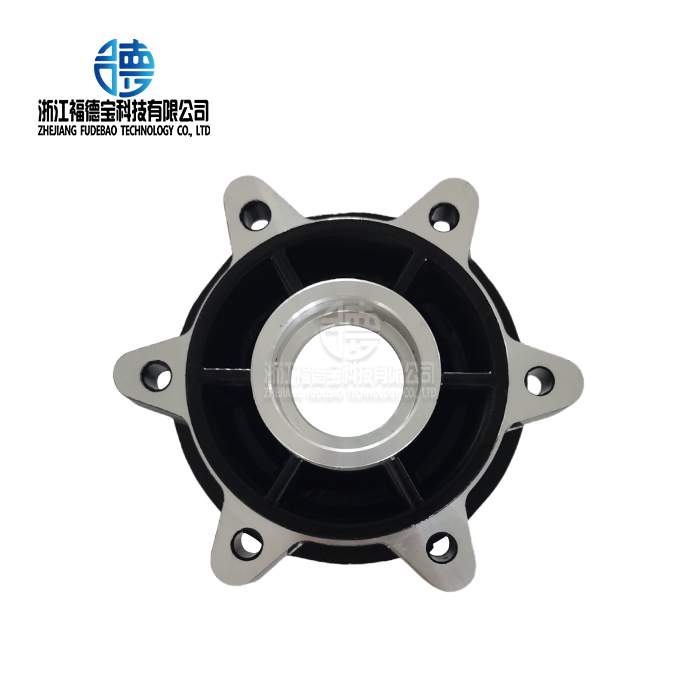

Structural Chassis Brackets and Mounting Systems

Precision-engineered mounting mounts produced by aluminum die casting hold important parts in place while absorbing working loads and shocks are essential for automotive frame systems. With high pressure die casting technology, complicated bracket shapes can be made, complete with built-in support ribs and the best possible weight distribution.

Traditional ways of making things would take a lot of welding or mechanical assembly to put these structure parts together because they usually have fixing places that can go in more than one direction. The aluminum die casting method makes solid structures that are more resistant to wear and have the same material qualities all the way through the part.

For electric car uses, new clamp designs include complex cooling system integration. Battery attachment clamps have thermal management tubes that help keep the temperature in check while the battery is being charged and while it is being used. The design of the die casting mold can handle these complicated interior shapes while still keeping the structural stability needed to meet crash safety standards.

As part of the manufacturing process, improved draft angle specs are used to make it easier to remove parts while reducing the amount of cutting that needs to be done. Secondary operations focus on important fixing areas that need to be perfectly lined up with components that fit together. Quality control steps make sure that the casting weight stays the same and the sizes are correct across all production amounts.

Surface treatment choices improve protection to rust and the way the surface looks. Powder finishing and anodizing techniques made for cars make things last a long time in tough settings. These finishing methods make the aluminum alloy base beneath it blend in perfectly. This makes parts that look good and work well for the whole life of the car.

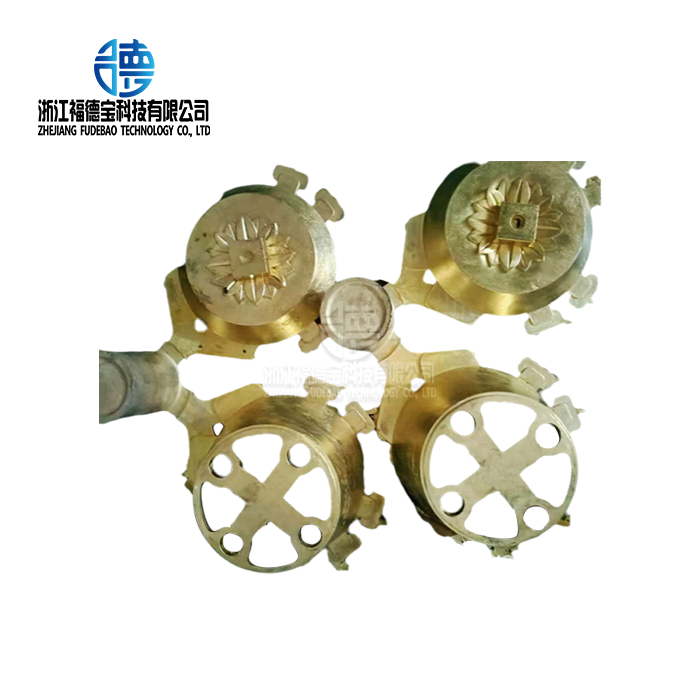

Engine and Powertrain Housings

These days, modern car powertrains need housing parts that can handle high operating loads and keep their exact dimensions. With aluminum die casting technology, engine housings are made with cooling channels, mounting bosses, and access ports built right in. These features make assembly easier and better combine parts.

The high pressure die casting process makes it possible to make pieces with thin walls that decrease the weight of the whole part without affecting its structural performance. Modern pressure die casting machine technology carefully controls the flow patterns of metal, reducing casting flaws and making sure that the material is evenly distributed across complex housing shapes.

Thermal control is an important part of designing both gas-powered and electric powertrains. Die-cast housings have complex cooling systems built in that keep the right temperatures for operation. Electric motor housings have special heat-dissipating fins and thermal transfer lines that handle the heat that is made when the motor is running at high speeds.

For certain car uses, heat treatment methods make the mechanical qualities of die-cast housings better. Solution heat treatment and age processes make the material stronger while keeping its shape, which is important for precise assembly tasks. These heating processes are carefully managed to keep thin-walled parts and complex shapes from warping.

Critical sealing surfaces, bearing bores, and mounting connections that need to be very accurate in terms of size are what machining for aluminum die casting is all about. Modern methods of putting together cars require very precise tolerances, and CNC cutting makes sure that body parts meet those needs. Cutting techniques that are more advanced reduce machine stresses that could affect how well a part works.

Battery Enclosures and Thermal Management Systems

Electric car battery systems need special covering parts that protect the structure while also controlling temperature and keeping electricity from flowing. With aluminum die casting technology, complex internal shapes are used to make integrated box structures that are best for managing heat and integrating components.

The designs of battery enclosures include many useful parts, such as cooling channels, fixing points, places for electrical feedthroughs, and access panels. The aluminum die casting process makes these parts as solid pieces, so they are easier to put together and don't have the possible weak spots that come with bonded or physically joined options.

Advanced cooling system designs are used by thermal management systems inside battery cases to keep the temperature stable during charging and discharging processes. The complex internal channel networks of die-cast cooling plates make sure that water flows evenly across battery cell groups. The optimized casting cycle time makes sure that the wall thickness stays the same in these important heat transfer areas.

Electrical separation needs exact control over the finishing of the surface and the make-up of the material. Specific types of aluminum alloys give the needed electrical qualities while keeping the structure performance. Surface treatments make reliable walls for insulation that stop electricity from leaking while keeping heat conductivity.

Assembly integration features make it easier to make and maintain battery packs. Die cast cages have built-in lifting points, access panels, and service lines that make them easier to service and cut down on the time it takes to put them together. During the die casting model development step, these design elements are tweaked to make sure they can be made and that the parts will work well.

Global Market Characteristics and Regulatory Considerations

Different international car markets have different safety rules and performance standards that affect the specs of aluminum die casting parts. By understanding these market traits, producers can make goods that meet regional compliance standards and make the global supply chain work as efficiently as possible.

European car laws stress that vehicles should be environmentally friendly and easy to recycle throughout their entire lives. These goals can be met with aluminum die casting parts because the material can be recycled and the parts are lighter. Heavy metal parts are made to be lighter, which makes the vehicles more fuel-efficient and helps makers meet strict pollution rules.

In North America, crash safety performance and longevity in harsh working circumstances are given the most weight for components produced by aluminum die casting. Die-cast car parts have to work the same way even when they are exposed to a lot of different temperatures, road salt, and natural toxins. These tough operating needs can be met by advanced aluminum metal formulas and surface treatment technologies.

Asian auto markets rely on making cars more efficiently and cheaply while still keeping high quality standards. When choosing components, being able to make a lot of them at once and making the supply chain integration process easier become very important. The ability to make large amounts of parts consistently and on a large scale is made possible by the metal die casting method.

Purchasing Recommendations and Technical Considerations

To buy aluminum die casting parts successfully, you need to carefully look at the skills, quality processes, and technical knowledge of the suppliers. OEMs and tier-1 providers in the automotive industry have to look at a lot of things that affect the long-term performance of parts and the stability of the supply chain.

A review of a company's production capabilities should focus on its die casting mold design skills and high-precision manufacturing tools. Suppliers who use advanced pressure die casting machines and complex process control systems can make sure that the parts are consistent and the right size. The ability to do metal flow simulations shows that an engineer has advanced skills in improving the design of parts and the manufacturing process.

Quality management systems must show that they follow the rules and methods of constant growth in the car business. Suppliers can meet the strict quality standards needed for car uses with ISO/TS 16949 approval and the ability to provide PPAP paperwork. Statistical process control systems and advanced testing technologies make sure that important safety parts are of high quality.

Professional providers are different from product producers because they can offer technical help. Expertise in engineering in choosing the right aluminum metal, optimizing heat treatment, and cleaning the surface makes sure that parts meet the needs of their particular applications. Collaborative design support helps improve the performance of parts while keeping the ability to make them.

Industry Trends and Market Evolution

Electric cars and other advanced industrial technologies are becoming more common in the auto business. These changes open up new uses for aluminum die casting. The use of electric vehicles increases the need for lightweight parts that can better handle heat. Precision housings for electrical parts are needed for advanced driving aid systems. Because of these trends, aluminum die casting is becoming an even more important tool for making cars.

Conclusion

High-quality aluminum die casting parts are the basis of modern auto making. They provide the perfect mix of light weight, structural strength, and production speed that today's cars need. Understanding the technical issues, quality standards, and seller abilities talked about in this guide helps you make smart purchasing choices that will help your manufacturing business succeed in the long run. As electric cars and other advanced automotive technologies keep getting better, precise die casting will become even more important in automobile uses.

FAQs

Why aluminum die casting is better than other ways of making parts for cars?

In high-volume production, aluminum die casting provides very accurate measurements, the ability to work with complex shapes, and great surface finishes. The process makes parts that are strong but not too heavy, and they have built-in features that would normally take several steps to put together. It is also cost-effective for car uses because it has a short casting cycle time and few extra processes.

How do die-cast metal parts improve the performance of electric vehicles?

Die-cast metal parts are very light, which makes the battery last longer and improves the way heat is managed in the cooling systems for the battery and motor. The light metal parts help the vehicle's center of gravity be as low as possible and make it easier to control. Putting an advanced cooling system inside die-cast housings keeps computer parts and battery systems running at the right temperature.

What quality standards should people who buy cars from makers of aluminum die castings expect?

Professional sellers of car parts should keep their ISO/TS 16949 approval and provide full PPAP paperwork. You can expect key features to have measurement limits of within ±0.05mm, material traits that stay the same thanks to statistical process control, and advanced checking tools like coordinate measuring machines and non-destructive testing. Surface cleaning should meet standards for how cars look and how well they prevent rust.

Partner with Fudebao Technology for Superior Automotive Casting Solutions

Fudebao Technology has a wide range of industrial skills and a lot of experience in the car business, which can help automakers find trusted aluminum die casting suppliers. Our factory has high-tech pressure die casting machines, high-speed CNC machining centers, and full surface treatment facilities, so we can deliver everything from raw materials to finished parts all in one place. We can hold precise standards of up to 0.05 mm and have a lot of experience working with car OEMs around the world. This means we can give your projects the technical know-how and quality assurance they need. Email us at hank.shen@fdbcasting.com to talk about your unique needs for car casting.

References

Smith, J.A. "Advanced Aluminum Die Casting for Automotive Applications: Materials Science and Manufacturing Techniques." Journal of Automotive Engineering, Vol. 234, No. 8, 2023, pp. 1245-1267.

Chen, L.M. et al. "Thermal Management Systems in Electric Vehicle Battery Enclosures: Design Optimization and Manufacturing Considerations." International Conference on Electric Vehicle Technology, 2023, pp. 89-104.

Rodriguez, P.K. "High Pressure Die Casting Process Optimization for Automotive Structural Components." Materials and Manufacturing Processes, Vol. 38, No. 12, 2023, pp. 1456-1478.

Thompson, R.W. "Lightweight Metal Components in Modern Automotive Design: Performance Analysis and Manufacturing Strategies." Automotive Technology Review, Vol. 45, No. 3, 2023, pp. 23-41.

Kumar, S.V. "Quality Assurance in Automotive Die Casting: Statistical Process Control and Inspection Technologies." Quality Engineering International, Vol. 29, No. 6, 2023, pp. 334-352.

Davis, M.H. "Surface Treatment Technologies for Automotive Aluminum Castings: Corrosion Resistance and Aesthetic Considerations." Surface and Coatings Technology, Vol. 467, 2023, pp. 129-145.

_1756346613780.webp)

_1756348300182.webp)

_1756349957728.webp)

_1756361423150.webp)