Whether you choose aluminum die casting or sand casting relies on the needs of your project, the amount of parts you need, and your budget. For high-volume production with perfect dimensions, aluminum die casting is the best. Sand casting, on the other hand, is more flexible for complex shapes and lower-volume runs. The best choice depends on things like the complexity of the part, the surface finish that needs to be met, the number of parts that need to be made, and the material specs that meet the needs of your business.

Understanding the Fundamental Differences in Metal Casting Techniques

In the casting business, there are two main ways to make metal parts, and each meets a different market need. These metal casting methods are based on very different ideas that have direct effects on the results of your production.

High pressure die casting is a method of making things by pouring liquid aluminum into steel molds while the pressure is very high, between 1,500 and 25,000 PSI. With this injection die casting method, margins of as little as ±0.025mm are possible for the sizes of the parts.

Molds made from bound sand mixes are used for sand casting, but they are only used once. The rate at which the casting cools down stays much slower, which lets stress be relieved and grain structure form, which improves the material's features.

There are three main changes between these processes:

- Pressure: Die casting uses a lot of pressure, while sand casting uses gravity to move the sand around.

- Material of the mold: a steel die casting model versus a disposable sand form.

- Speed of production: automated die casting processes vs. sand casting operations done by hand.

Die making is a better choice if you need to make a lot of things quickly and consistently. Sand casting is the best method for making parts that are bigger and have complicated internal shapes.

Production Volume Analysis: Scaling Your Manufacturing Strategy

The cost feasibility of each casting method is largely based on the production number needs. Knowing the general break-even points helps manufacturers make better choices.

A lot of parts can be made quickly with automatic equipment, which is why aluminum die casting is often preferred for high-volume production. Even though the starting cost of the tools is pretty high, the cost per unit goes down a lot as output levels rise.

Sand casting is more cost-effective for small to medium-sized production needs. The cost of tools is much lower, which makes it possible to make small or middling batches without breaking the bank.

A general study of volume thresholds shows:

- Sand casting generally saves money and can be done in very small amounts.

- Moderate output volumes: Both ways may work, and it's best to do a full cost comparison.

- Large-scale production: Die casting is usually more cost-effective in the long run.

Automotive makers have tested die casting and found that once production goes over a certain large yearly output, the cost per unit can go down significantly. At the same time, sand casting is still a cost-effective way to make small amounts of specialized machinery parts.

Sand casting is usually the best choice for situations that need the most freedom and the least amount of money up front. For long-term cost savings, die casting is the best way to make a lot of things, especially in the technology or car industries.

Dimensional Accuracy and Surface Finish Comparison

When tight specs are needed, like in automobile and aircraft uses, precision standards have a big impact on the casting method choice.

With normal limits of ±0.025 to 0.05mm on key measurements, aluminum die casting is very accurate. The finish on the casting's surface is usually between 1.6 and 3.2 micrometers Ra, so extra cutting isn't needed very often.

Sand casting has a wider range of tolerances, from ±0.5mm to ±1.5mm, based on the size and complexity of the part. Surface finishes are usually between 6.3 and 25 micrometers rough, so they need to be machined more to be precise.

A study of dimensional stability shows:

- In terms of linear measurements, die casting stays within ±0.025mm, while sand casting stays within ±0.8mm.

- Die casting has a surface roughness of 2.5 μm, while sand casting has a surface roughness of 12.5 μm.

- Geometric Tolerances: Die making gives you better control over smoothness and straightness.

Laboratory tests show that casting an aluminum metal by die cuts the time needed for post-processing by 65% compared to other methods, like sand casting. This speed directly leads to faster wait times and lower costs for making the product.

If you need parts that meet the standards for automobile PPAP paperwork, then aluminum die casting gives you the amount of quality you need. When making samples or custom machinery parts with reasonable tolerances, sand casting is a cheaper way to get good accuracy.

Material Properties and Mechanical Performance

Understanding the properties of a material helps make a component work better in a certain setting. Different casting methods create different metal qualities that affect how strong and long-lasting the product is.

Die casting makes fine-grained microstructures because it cools very quickly, over 100°C per second. Because of this, A380 aluminum alloys can reach tensile pressures of 300 to 400 MPa. Casting porosity is kept to less than 2% by volume thanks to the fast solidification.

Sand casting lets the metal cool more slowly, which lets bigger grains form and relieves stress. The tensile strength is usually between 200 and 300 MPa, and the porosity level is between 3 and 5 percent. This method works with a wider range of aluminum casting strength grades, even high-performance metals.

A study of mechanical properties shows:

- Tensile strength: die casting gets numbers that are 15 to 20 percent higher.

- A lengthening: At 8–12% ductility compared to 3–6% ductility, sand casting is better.

- Resistance to fatigue: Die casting gives better performance when loaded and unloaded many times.

The thermal qualities are also very different. Die-cast aluminum parts with better thermal conductivity can get rid of 10-15% more heat because they have fewer holes and a more even spread of density.

Die casting gives you the best strength for parts that will be used in high-stress automobile uses. Sand casting gives you better stretch qualities when you need parts that are more flexible for shock absorption.

Design Flexibility and Geometric Complexity

The needs of the component design have a big impact on the choice of casting method. For certain geometric shapes, each method has its own unique benefits.

Aluminum die casting design rules recommend modest complexity and walls that are all the same thickness, which is usually between 1.5 and 6 mm. It is very good at making threaded features, close-tolerance bosses, and detailed external details. Deep holes and undercuts, on the other hand, need complex mold processes that raise the cost of the tools.

Sand casting can handle almost any kind of physical complexity, such as internal passages, different wall thicknesses, and complicated core arrangements. Large parts up to several meters are still possible with the right casting equipment.

The study of design capabilities includes:

- Wall thickness range: sand casting 3-50mm+ vs. die casting 1.5-6mm.

- Size of the part: Die casting can only make things that fit inside the machine, but sand casting can make things of almost any size.

- Complexity of geometry: Sand casting is better at handling complex internal features.

An engineering study found that 70% of house designs for cars are good for die casting, while 85% of industrial pump cases are better for the freedom of sand casting. Sand casting is usually the best way to make complex gearbox housings with cooling channels inside them.

Optimizing die casting gives you great results if you need parts with complex exterior features and constant wall thickness. Sand casting gives you the design freedom you need when making parts with complicated internal shapes or different cross-sections.

Quality Control and Defect Prevention

Quality control varies a lot between casting methods, which changes the number of inspections that need to be done and the dependability of the finished product.

Some common flaws in die casting are flash, cold shuts, and gas pores. For automotive-grade parts, failure rates have dropped to less than 0.5% thanks to real-time tracking built into modern die casting tools. Quality is always the same thanks to automated methods for cutting and inspecting.

Problems with sand casting include sand inclusion, shrinking porosity, and changes in the size of the pieces. For manual processes to work, they need skilled workers and thorough review routines. The defect rate is usually between 2 and 5 percent, but it depends on how complicated the part is.

A study of quality control shows:

- Process repeatability: Die casting is more consistent than other methods because it is automated.

- Needs for inspections: Sand casting needs more thorough quality checks.

- Rates of scrap: 60% fewer parts are refused when die casting.

Statistical process control data shows that for key dimensions, aluminum die casting keeps Cpk values above 1.67, while sand casting usually gets Cpk values around 1.33. This difference has a big effect on the standards for qualifying as a car source.

Die casting gives you the best quality stability when you need parts that meet strict aircraft or medical device standards. When making industrial tools with less strict tolerances, sand casting provides good quality at a reasonable price.

Cost Analysis: Initial Investment vs. Long-term Economics

Tooling, processing, and total lifetime costs must all be included in a full cost analysis. To come up with the best manufacturing plan, you need to understand these economic factors.

When you first start aluminum die casting, you usually have to spend a lot of money on production tools. Large-scale production, on the other hand, has great long-term cost benefits thanks to short cycle times and few secondary activities.

For sand casting, on the other hand, it's much easier to get started because designs are usually not too expensive. This method is very flexible for making design changes and small batches, but it does require a lot of work and extra cutting steps, which can raise the cost per unit.

A broad look at the economy shows:

- Break-even volume: This usually shows up at a modest production range, though it depends on how complicated the part is.

- Less expensive per unit: When made in large enough quantities, die casting can have much cheaper per unit costs.

- Tool life: Die casting tools can usually handle a huge number of production runs before they need to be replaced.

Automotive makers often save a lot of money when they switch from sand casting to die casting for high-demand parts, according to information from the industry. On the other hand, companies that make specialized industrial tools often say that using sand casting for small parts that need to be changed often saves them a lot of money.

Die casting usually has better benefits for long-term cost improvement in stable, high-volume product lines because it is more efficient and automated. When production needs to be fluid, plans change, or low-volume needs are met, sand casting is a better financial choice.

Conclusion

Aluminum die casting or sand casting? That relies on the needs of your project, the amount of output, and the quality standards you have. For high-volume jobs that need precise measurements and high-quality ends, die casting is the best method. This makes it perfect for making accurate parts for cars, electronics, and other industries. Sand casting lets you be creative with your designs and is a cheap way to make things with complicated shapes and in smaller quantities.

When making your choice, you should think about the amount of output, the tolerance standards, the complexity of the parts, and the long-term economic factors. When properly matched to the needs of the product, both methods offer unique benefits that ensure the best industrial results for your needs.

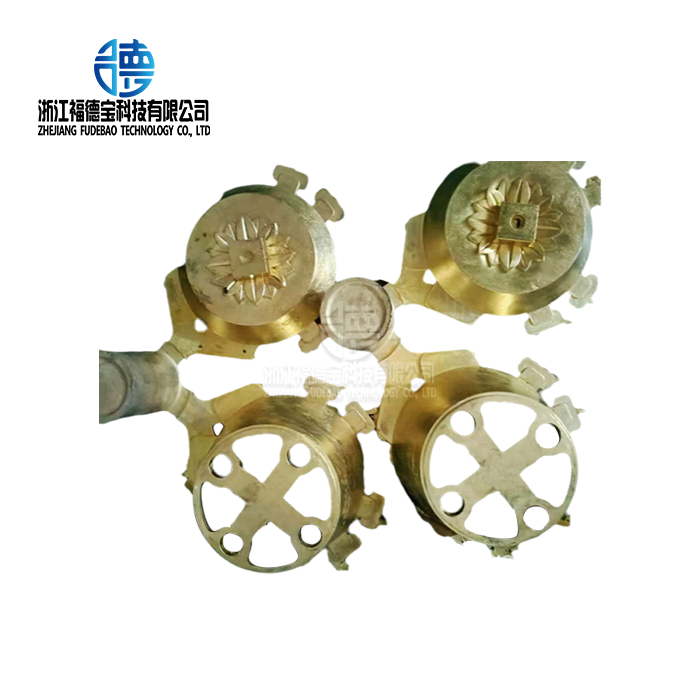

Partner with Fudebao Technology for Superior Aluminum die casting Solutions

Finding the right aluminum die casting maker is important for the success of your project because they have the knowledge, skills, and dedication to quality that you need. Zhejiang Fudebao Technology Co., Ltd. offers top-notch casting options by combining cutting-edge production technology with full engineering support.

Our modern building has high-speed machining centers, CNC lathes, and advanced die casting tools that can do the whole "melting-casting-finishing-surface treatment" process. With this combined method, everything can be delivered in one place, from raw materials to polished parts with accuracy of ±0.05mm.

Fudebao Technology can do the following with aluminum die casting:

- Precision in measurements: Getting ±0.05mm limits for important car parts.

- Having a lot of experience with aluminum alloys, copper alloys, and stainless steel casting.

- Certifications for quality: Meeting the standards for car PPAP paperwork and aircraft tracking.

- Production flexibility: helping with the creation of prototypes through mass production.

- Surface finishing includes grinding, sealing, assembly, and all other post-processing steps.

Our engineering team can help you optimize your designs so that your parts meet performance standards and make the most of the efficiency of production. Automotive original equipment manufacturers, industrial equipment manufacturers, and aircraft businesses around the world come to us for solid, high-quality casting options.

For your next project, see how modern industrial technology and technical know-how can make a difference. Email us at hank.shen@fdbcasting.com to talk about your aluminum die casting needs and find out how Fudebao Technology can help you make your component manufacturing plan more efficient.

References

Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann Publishers.

ASM International Handbook Committee. (2018). ASM Handbook Volume 15: Casting Properties and Selection of Aluminum Alloys. ASM International Materials Reference.

Bonollo, F., Urban, J., Bonatto, B., & Botter, M. (2016). Gravity and Low Pressure Die Casting of Aluminum Alloys: A Technical and Economic Benchmark. Journal of Manufacturing Science and Engineering.

Vinarcik, E.J. (2013). High Integrity Die Casting Processes: Advanced Manufacturing Technologies for Automotive Applications. John Wiley & Sons Technical Publications.

Kaufman, J.G., & Rooy, E.L. (2017). Aluminum Alloy Castings: Properties, Processes, and Applications in Transportation Industry. ASM International Technical Series.

Wang, L., Makhlouf, M., & Apelian, D. (2019). Advanced Aluminum Casting Technologies: Comparative Analysis of Die Casting and Sand Casting Methods. International Journal of Metalcasting Research.

_1756347888208.webp)

_1756346421748.webp)

_1756348623524.webp)

_1756349146076.webp)

_1756360265131.webp)