Aluminum casting bracket

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Aluminum Casting Brackets: Precision-Engineered Solutions by Zhejiang Fudebao Technology

Zhejiang Fudebao Technology Co., Ltd is your trusted manufacturer and supplier of high-quality aluminum casting brackets. We have been experts in precision casting for 24 years, so we can make products that meet the high standards of industries around the world. For your toughest jobs, our products are the strongest, most durable, and most cost-effective you can find.

Product Description

Our products are made to work well in a lot of different industrial settings. These clamps are very strong and precisely sized thanks to the new low-pressure and gravity casting methods that were used to make them. Because they are strong but not too heavy, our products work well in industries that need to reduce weight, like the automotive, aerospace, and equipment industries.

Parameters

| Parameter | Specification |

|---|---|

| Material | ADC12, A356, A380 Aluminum Alloys |

| Casting Process | Low Pressure, Gravity Casting |

| Surface Finish | As-cast, Machined, Anodized |

| Tensile Strength | ≥280 MPa |

| Dimensional Tolerance | ±0.05mm |

| Weight Range | 0.5 kg - 20 kg |

| Minimum Wall Thickness | 3 mm |

Product details pictures

Applications

- Automotive chassis and engine components

- Industrial machinery frames and supports

- Aerospace structural elements

- Construction equipment brackets

- Renewable energy system mountings

Company Profile

Zhejiang Fudebao Technology Co., Ltd, established in 2001, has grown into a leading force in precision metal casting. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses cutting-edge equipment for comprehensive production capabilities. Serving global names in the automotive, industrial, and energy sectors, we're proud of our dedication to new ideas, high quality, and happy customers. Multiple patents and a strict quality management system back up our skill in aluminum casting brackets.

Why Choose Us?

- 24 years of specialized experience in precision casting

- Advanced manufacturing technology with ±0.05mm accuracy

- Comprehensive in-house production for cost-effective solutions

- Customization capabilities to meet specific industry needs

- Strong R&D focus with patented innovations

- Strict quality control adhering to international standards

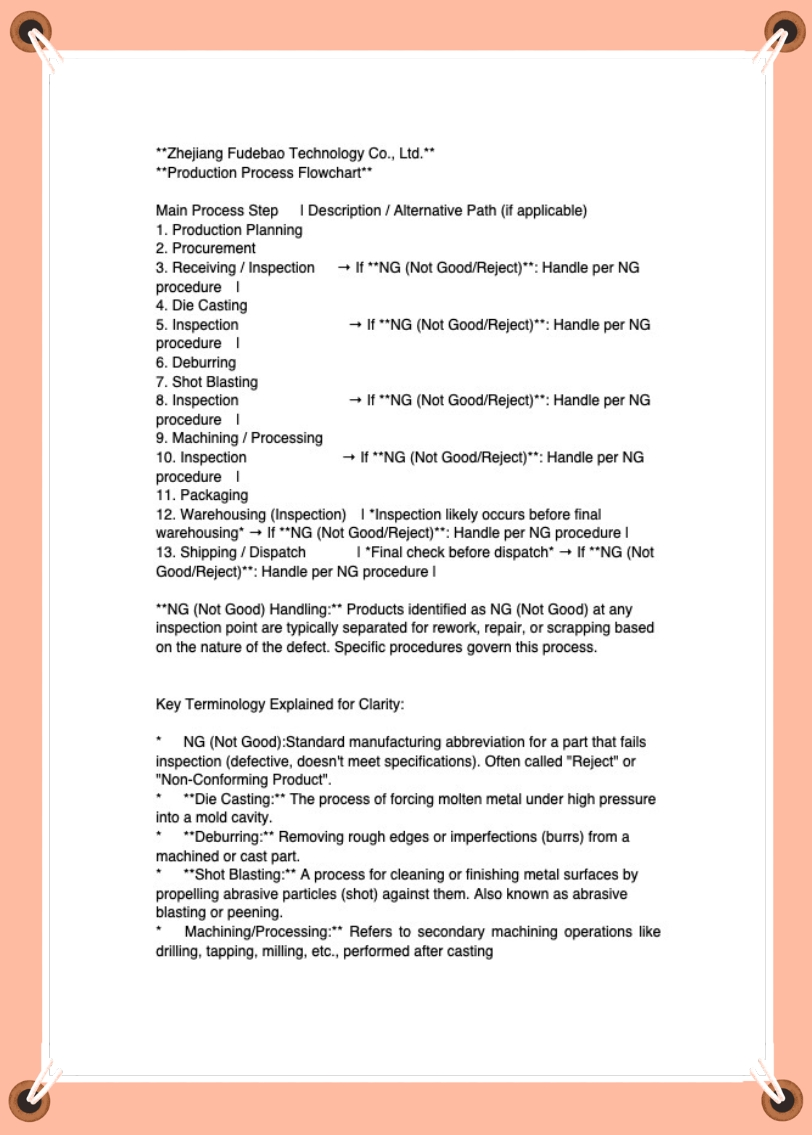

Production Process

- Design and Engineering

- Mold Making

- Alloy Preparation

- Casting (Low Pressure/Gravity)

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment

- Final Assembly and Packaging

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- ISO 14001 Environmental Management System

Packaging and Shipping

- Custom packaging to ensure product integrity

- Global logistics partnerships for efficient delivery

- Flexible shipping options to meet your timeline

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible MOQs starting from 100 pieces, depending on the complexity and size of the bracket.

Q: Can you provide custom designs for the products?

A: Absolutely! Our engineering team can work with your specifications to create custom products tailored to your needs.

Q: What is the lead time for production?

A: Standard lead times range from 3-4 weeks, but we can accommodate rush orders when possible.

Q: Do you offer samples before full production?

A: Yes, we provide sample production services to ensure the product meets your requirements before mass production.

Contact Us

Ready to elevate your projects with our premium aluminum casting brackets? Contact our expert team today for a personalized consultation and quote.

Email: hank.shen@fdbcasting.com

Experience the Fudebao difference – where precision meets innovation in products.

_1756348623524.webp)

_1756348780785.webp)

_1756349002499.webp)

_1756349071334.webp)

_1756349146076.webp)

_1756349957728.webp)

_1756350046757.webp)