Battery housing lower box casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:cast aluminum mold

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Battery Housing Lower Box Casting - Precision and Performance

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer and supplier of high-quality battery housing lower box casting solutions. With 24 a long time of skill in accuracy casting, we offer predominant items that meet the requesting needs of electric vehicle producers and vitality capacity suppliers. Our product stands out for its uncommon solidness, warm administration properties, and cost-effectiveness.

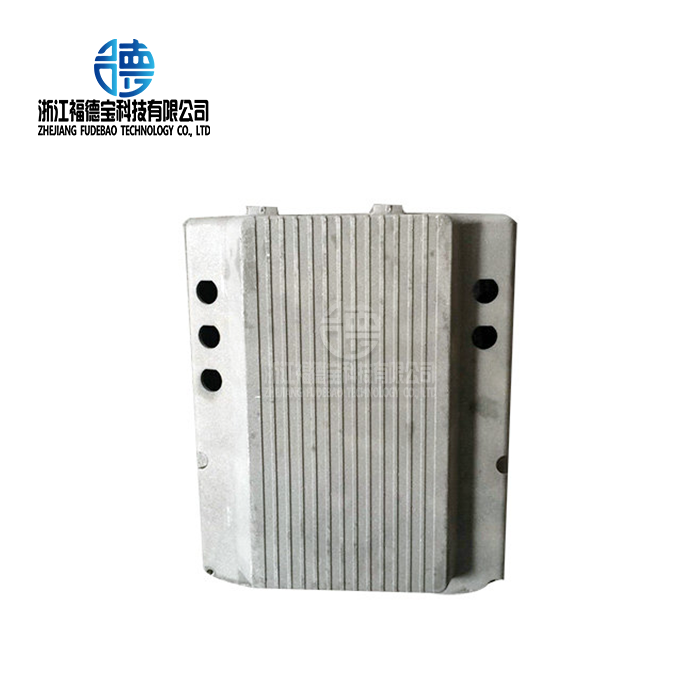

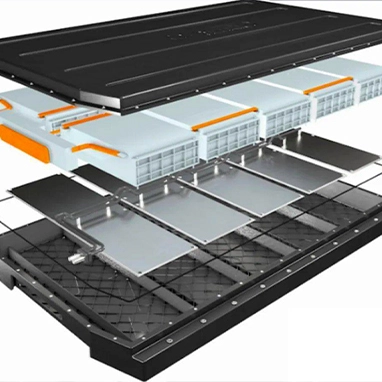

Product Description

Our product is designed to give ideal assurance and execution for battery frameworks in electric vehicles and vitality capacity applications. Made from high-grade aluminum amalgam, it offers great strength-to-weight proportion, erosion resistance, and warm conductivity.

Parameters

| Specification | Detail |

|---|---|

| Material | Aluminum Alloy (A356-T6) |

| Casting Method | Low Pressure Die Casting |

| Surface Finish | As-cast / Machined |

| Dimensional Tolerance | ±0.05mm |

| Wall Thickness | 3-5mm |

| Weight | 5-15kg (customizable) |

| Thermal Conductivity | >150 W/m·K |

| Tensile Strength | ≥280 MPa |

| Production Capacity | 10,000 pcs/month |

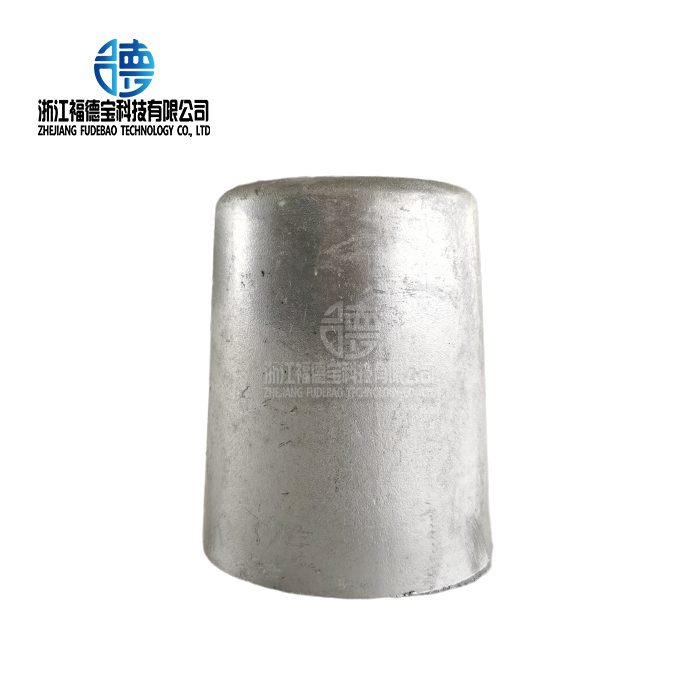

Product details pictures

Applications

- Electric Vehicle Battery Packs

- Stationary Energy Storage Systems

- Industrial Battery Modules

- Marine and Aviation Battery Enclosures

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang, is equipped with advanced machinery, enabling us to deliver top-tier metal components to global industries. For the energy, automobile, and industrial equipment industries, we make castings out of aluminum alloy, copper alloy, and stainless steel. Leaders in many industries trust us to work with them because we are dedicated to new ideas and high quality.

Why Choose Us?

- Expertise: 24 years of specialized experience in metal casting and precision machining.

- Quality: ISO 9001 certified with stringent quality control measures.

- Customization: Tailored solutions to meet specific customer requirements.

- Cost-Efficiency: Competitive pricing without compromising on quality.

- Reliability: On-time delivery and excellent after-sales support.

Production Process

- Design Optimization and Mold Creation

- Material Selection and Preparation

- Low Pressure Die Casting

- Heat Treatment

- CNC Machining and Finishing

- Quality Inspection and Testing

- Surface Treatment (if required)

- Packaging and Shipping

Certificates

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- IATF 16949:2016 Automotive Quality Management System

Packaging and Shipping

- Custom-designed packaging to ensure product protection

- Wooden crates or pallets for bulk orders

- Global shipping options available

- Fast and reliable delivery to meet your production schedules

FAQ

Q1: What is the minimum order quantity for battery housing lower box casting?

A1: Our minimum order quantity is typically 100 pieces, but we can accommodate smaller orders for prototyping or special requirements.

Q2: Can you provide samples before bulk production?

A2: Yes, we offer sample production services to ensure the product meets your specifications before large-scale manufacturing.

Q3: What is the lead time for the product?

A3: Standard lead time is 4-6 weeks, depending on order quantity and complexity. Rush orders can be accommodated upon request.

Q4: Do you offer design assistance for the product?

A4: Absolutely. Our engineering team provides free DFM (Design for Manufacturing) analysis and optimization suggestions to enhance product performance and reduce costs.

Contact Us

Ready to elevate your battery systems with our superior product? Contact Zhejiang Fudebao Technology Co., Ltd. today for a customized quote and expert consultation.

Email: hank.shen@fdbcasting.com

Let's collaborate to create the perfect battery housing lower box casting solution for your innovative energy projects!

YOU MAY LIKE