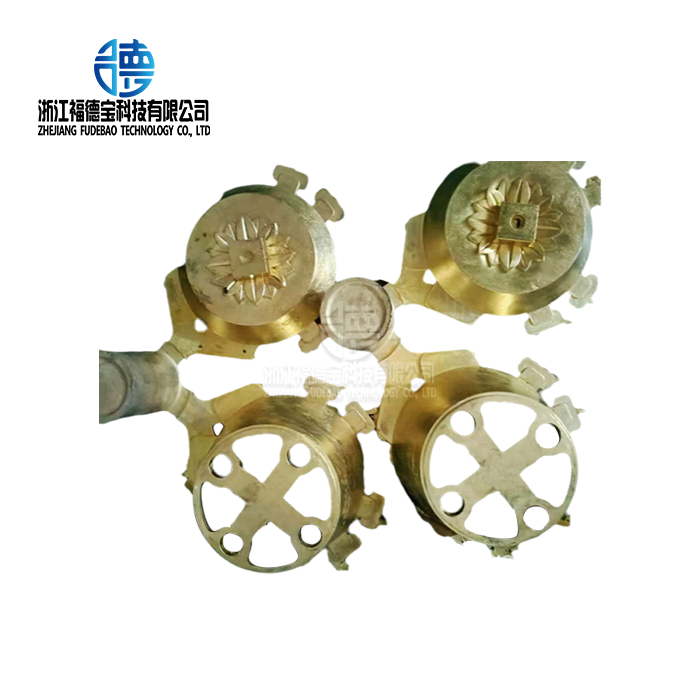

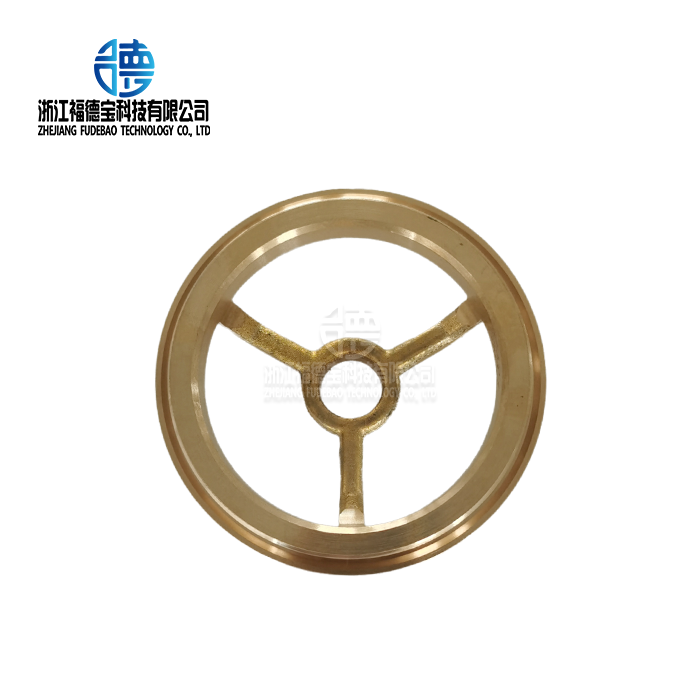

Cryopump body

texture:copper

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:copper die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Cryopump Body: High-Performance Vacuum Solutions

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer and supplier of high-quality Cryopump body components. With 24 a long time of mastery in exactness casting, we convey prevalent product arrangements that meet the requesting needs of semiconductor fabricating, investigate teach, and aviation businesses. Our progressed fabricating forms guarantee unparalleled exactness, unwavering quality, and execution for your basic vacuum applications.

Product Description

Our product is designed to give remarkable warm cover and auxiliary judgment for cryogenic pumping frameworks. Made from premium-grade materials, these bodies offer prevalent vacuum soundness and life span, making them perfect for ultra-high vacuum situations in semiconductor generation and logical investigate.

Parameters

| Specification | Value |

|---|---|

| Material | 6061-T6 Aluminum Alloy |

| Surface Finish | Ra ≤ 0.8μm |

| Vacuum Rating | 10^-10 Torr |

| Temperature Range | -269°C to +150°C |

| Flange Type | CF (ConFlat) |

| Customizable Sizes | 4" to 20" diameter |

Product details pictures

Applications

- Semiconductor manufacturing equipment

- Thin film deposition systems

- Space simulation chambers

- Particle accelerators

- Cryogenic research facilities

- MRI systems

- Semiconductor

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been at the forefront of precision metal casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses advanced equipment for comprehensive metal processing. We specialize in aluminum amalgam, copper amalgam, and stainless steel components, serving worldwide businesses with our commitment to quality and advancement. Our skill in cryogenic innovations positions us as a trusted accomplice for high-performance vacuum arrangements.

Why Choose Us?

- Precision Manufacturing: Our high-speed machining centers and CNC lathes achieve tolerances of ±0.05mm.

- Material Expertise: We use specially formulated alloys for optimal cryogenic performance.

- Customization: Tailored solutions to meet your specific Cryopump body requirements.

- Quality Assurance: ISO 9001 certified processes ensure consistent, high-quality products.

- Global Support: Comprehensive after-sales service and technical assistance worldwide.

Production Process

- Material Selection and Testing

- CNC Machining of Body Components

- Precision Welding and Assembly

- Surface Treatment and Finishing

- Vacuum Leak Testing

- Final Inspection and Quality Control

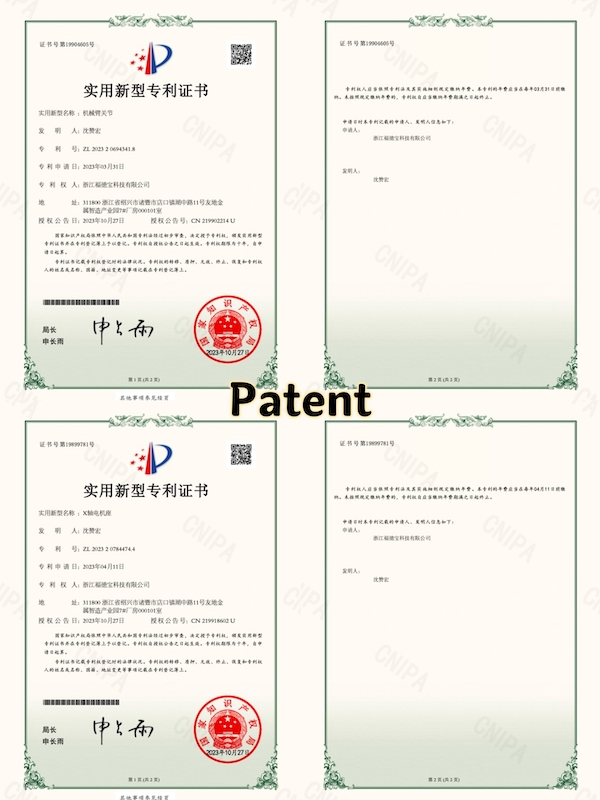

Certificates

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- ASME Section IX Welding Certification

- RoHS Compliance Certificate

Packaging and Shipping

- Custom-designed protective packaging for each product

- Vacuum-sealed to prevent contamination

- Shock-absorbing materials for safe transportation

- Global logistics support with tracking

FAQ

Q: What is the typical lead time for a custom product?

A: Lead times vary based on specifications, but generally range from 4-6 weeks for standard sizes and 6-8 weeks for custom designs.

Q: Can you provide material certifications for traceability?

A: Yes, we provide full material certifications and traceability documents for all our products upon request.

Q: Do you offer on-site installation support?

A: We provide comprehensive installation guidance and can arrange on-site support for complex integrations as needed.

Q: What warranty do you offer on your Cryopump bodies?

A: We offer a standard 12-month warranty against manufacturing defects, with extended warranty options available.

Contact Us

Ready to elevate your vacuum system performance? Contact our Cryopump body experts today for a customized solution:

- Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology Co., Ltd. power your next-generation cryogenic pumping systems with our precision-engineered product components.

_1756361423150.webp)

_1756361494985.webp)