Where to Source Low Pressure Casting Parts Worldwide?

2026-01-21

Knowing which areas provide the finest balance of quality, affordability, and technological know-how is essential to locating trustworthy suppliers for low pressure casting components worldwide. China, Germany, Italy, and the US are important sourcing locations that provide specific skills in casting aluminum and copper alloys. European vendors concentrate on precise engineering for aerospace applications, whereas Chinese manufacturers excel in providing cost-effective solutions with sophisticated automation. Automotive OEMs are usually provided with PPAP documentation and quick prototyping services by American foundries. The secret is to match suppliers that have shown proven experience in your particular area with your unique criteria, whether they be dimensional precision, material qualities, or certification standards.

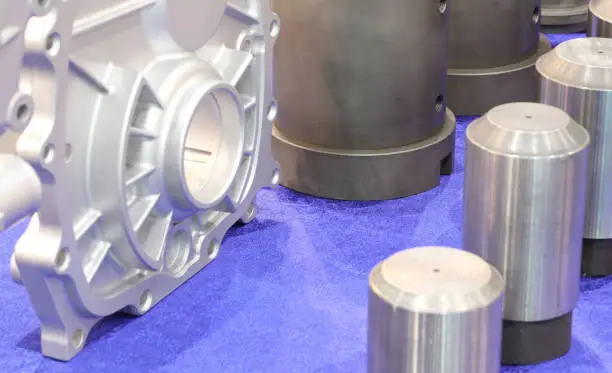

Understanding Low Pressure Casting and Its Industry Applications

Melted metal enters molds using a regulated air pressure, usually between 0.2 and 1.0 bar, in a complex manufacturing process known as low pressure casting. When compared to gravity casting processes, this precise technology guarantees greater material density and mechanical qualities. Melted copper or aluminum alloys are first heated to ideal temperatures before being moved into permanent molds via sealed systems.

Controlling the temperature is essential to maintaining a constant level of quality throughout the casting cycle. Modern foundries have accurate thermal management systems that keep an eye on metal temperatures within tolerances of ±5°C. This degree of control guarantees consistent grain structure across the component and avoids frequent flaws like cold shuts.

Comparing Low Pressure Casting with Alternative Methods

Procurement experts often contrast low pressure casting with die casting and investment casting methods when assessing production possibilities. For medium- to large-scale production runs, low pressure casting provides clear cost benefits while preserving excellent surface quality. This technique, in contrast to high-pressure die casting, lowers turbulence during mold filling, which leads to improved mechanical qualities and fewer internal flaws.

Even while investment casting has a superior surface polish, it usually requires more expensive tools and longer lead times. Low pressure casting is especially well-suited for electrical enclosures, industrial pump components, and automobile housings because it achieves the best possible balance between quality and manufacturing efficiency.

Material Versatility Across Industries

Traditional aluminum alloys are not the only materials that may be utilized in low pressure casting. Contemporary foundries use magnesium alloys for lightweight aircraft components, copper alloys for electrical uses, and specific aluminum-silicon combinations for automobile engine parts. The choice of each material is based on certain performance criteria, such as strength-to-weight ratios, corrosion resistance, and thermal conductivity.

Aluminum alloys A356 and A357 are very useful for automotive applications because they provide superior castability and heat treatment characteristics. Copper-based alloys are often used in industrial equipment components for improved heat management and wear resistance.

Global Sourcing Landscape for Low Pressure Casting Parts

The worldwide market for low pressure casting providers is spread across many continents, each of which has special benefits for certain application needs. European foundries continue to hold the top spots in precision casting for high-performance automotive and aerospace applications, especially in Germany and Italy. These establishments usually possess extensive certifications, such as IATF 16949 for automotive quality management and AS9100 for aerospace.

With their sophisticated automation and capacity for large-scale manufacturing, Asian manufacturers—particularly those in China and Japan—offer competitive alternatives. Modern low pressure casting machinery, including computer-controlled systems that guarantee constant process parameters across production runs, has been extensively invested in by Chinese foundries. Japanese providers concentrate on applications requiring outstanding dimensional accuracy and high precision.

Regional Specializations and Capabilities

North American suppliers are excellent at providing automakers with short lead times and quick prototype services. In order to provide just-in-time supply schedules, these foundries often retain co-location strategies close to important production centers. They are useful partners for tier-1 suppliers that need thorough quality documentation because of their proficiency with PPAP documentation and validation procedures.

When choosing suppliers, procurement managers should take into account the following important geographical advantages:

- European foundries satisfy the strict needs of the military sector by providing superior precision engineering with extensive aerospace certifications, excellent metallurgical skills, and full traceability systems.

- Through economies of scale, cutting-edge automation systems, and adaptable batch production capabilities appropriate for both prototype and high-volume manufacturing, Asian manufacturers provide cost-competitive solutions.

- North American suppliers are excellent at providing prompt customer service, quick turnaround times, and thorough technical assistance, which includes advice on material selection and design optimization.

Procurement teams may connect suppliers that have demonstrated competence in relevant application areas with particular project needs thanks to their regional specialties.

Supplier Evaluation Criteria

In order to choose a supplier successfully, a number of factors other than unit cost must be considered. Process capacity is fundamentally assured by quality management systems, such as ISO 9001 accreditation and industry-specific standards. Technical competencies include metallurgical understanding, mold design experience, and secondary machining skills that enable full part finishing.

Flexibility in production becomes essential when evaluating suppliers for a variety of product portfolios. The complexity of the supply chain is decreased while maintaining constant quality requirements when prototype quantities and production volumes may be managed in the same location.

Comparing Casting Methods to Make Informed Procurement Decisions

Understanding the technical trade-offs between different casting techniques helps procurement professionals select components for their applications. With better mold filling properties and less oxidation during the pouring process, low pressure casting has clear benefits over gravity casting. Even in intricate geometries with thin wall portions, the regulated pressure guarantees full mold cavity filling.

Faster cycle times are provided by high-pressure die casting, but it also comes with increased tooling costs and the possibility of internal porosity because to turbulent mold filling. These issues are resolved by low pressure casting, which creates better mechanical qualities and less machining allowances via a soft, regulated metal flow.

Quality Considerations and Defect Prevention

Procurement teams may create suitable quality requirements with suppliers by having a thorough understanding of typical problems. The most common issue in aluminum casting is porosity, which is usually caused by inadequate degassing or an excessive amount of hydrogen in the molten metal. To maintain metal purity requirements, reputable foundries use hydrogen analyzers and vacuum degassing equipment.

When metal streams don't bond correctly during mold filling, cold shuts happen. By using ideal gating design and regulated filling rates, low pressure casting reduces this danger. In order to save development time and guarantee first-article success, seasoned vendors enhance gating systems prior to tooling manufacturing using flow simulation software.

Performance Trade-offs and Cost Analysis

The effectiveness of material use varies greatly amongst casting techniques. By reducing runner volumes and optimizing gating systems, low pressure casting outperforms gravity casting in terms of material yield. When dealing with premium metals or strict budgetary constraints, this efficiency results into cheaper material costs per component.

The choice of approach is also influenced by lead time. Low pressure casting uses permanent molds that may be produced more quickly than investment casting, which requires lengthier tooling development times. Schedules for the launch of new products or demands for quick market reaction benefit greatly from this advantage.

How to Source Low Pressure Casting Parts Efficiently?

Before contacting possible suppliers, effective sourcing strategies start with a clear definition of the technical specifications and quality standards. Dimensional tolerances, material characteristics, surface finish parameters, and relevant industry standards should all be included in thorough specifications. Suppliers are able to offer precise quotes and see possible design optimization possibilities because to this clarity.

Suppliers may better grasp the whole project scope by creating request-for-quotation packages that contain comprehensive drawings, material specifications, and yearly volume predictions. More precise price and timing guarantees are made possible by including details regarding secondary activities, packaging specifications, and delivery timeframes.

Leveraging Digital Procurement Platforms

Through sophisticated search features and supplier verification systems, contemporary B2B procurement platforms expedite the supplier assessment and discovery procedures. In order to facilitate well-informed decision-making, these systems often include access to supplier capabilities databases, certification status, and customer feedback. Automated delivery tracking and purchase order processing are made possible by integration with enterprise resource planning systems.

Industry trade exhibitions continue to provide beneficial chances for in-person interactions with suppliers and technology evaluation. Concentrated access to foreign suppliers and cutting-edge technology is provided via events such as international foundry exhibits, CastExpo in the US, and GIFA in Germany. These locations allow for direct discussion of technical skills and the practical assessment of sample parts.

Building Strategic Supplier Relationships

Beyond transactional ties, successful global sourcing involves strategic alliances that advance long-term corporate goals. Frequent evaluations of suppliers, such as capability reviews and on-site audits, preserve quality standards while spotting areas for growth. Design optimization recommendations that save costs while enhancing product performance are often the result of collaborative collaborations.

When dealing with foreign suppliers for low pressure casting in various time zones and cultural situations, communication methods become especially crucial. Efficient project execution and prompt problem resolution are ensured by establishing clear communication channels, frequent review schedules, and escalation processes.

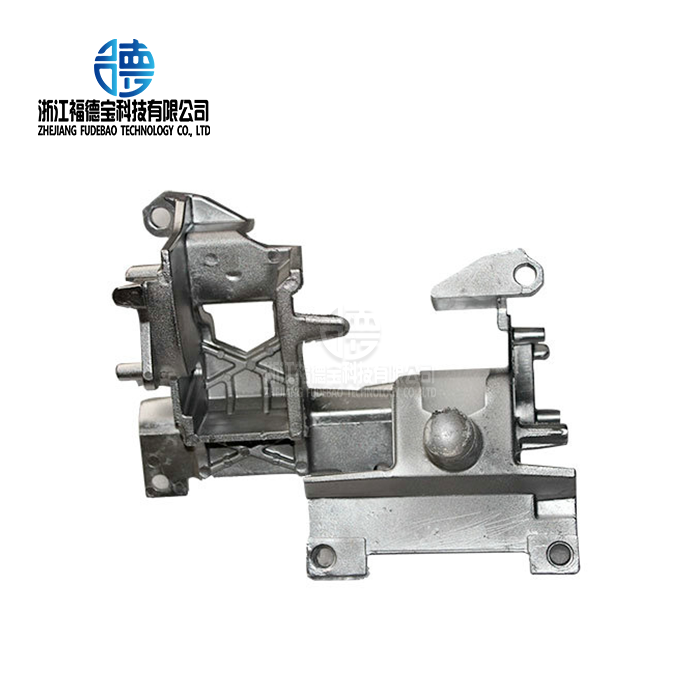

Our Company and How We Support Your Low Pressure Casting Needs

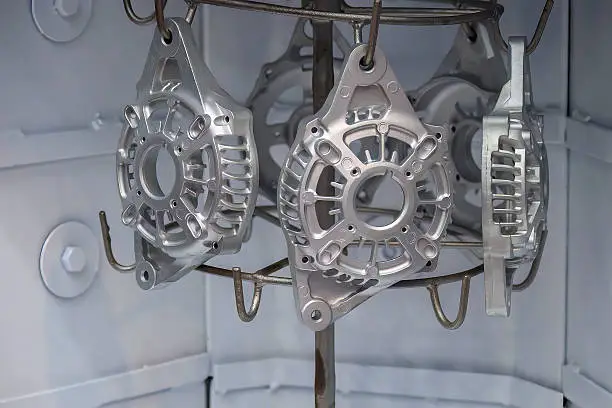

Serving customers worldwide in the automotive, industrial equipment, and aerospace industries, Zhejiang Fudebao Technology has made a name for itself as a leading company in aluminum foundry operations. Complex casting projects may be handled by a single source thanks to our extensive manufacturing facility, which combines the whole production process from melting to finishing processes.

Our technological capabilities include sophisticated low pressure casting equipment that maintains dimensional precision under ±0.05mm tolerances, CNC lathes, and high-speed machining centers. This level of accuracy satisfies the exacting specifications of aerospace applications where quality cannot be compromised, medical equipment housings, and automotive precision components.

Advanced Manufacturing Capabilities

For clients across the world, our facility's combination of melting, casting, and finishing activities offers a number of benefits. Compared to multi-vendor alternatives, simplified workflows shorten lead times, and unified quality control systems guarantee uniform standards throughout the manufacturing process. Aluminum alloys, copper alloys, and stainless steel materials appropriate for a variety of application needs are all covered by our metallurgical knowledge.

Anodizing, powder coating, and specialty finishes that satisfy industry-specific standards are examples of surface treatment capabilities. These services ensure total traceability throughout the manufacturing process and do away with the need for extra providers. Material certifications, dimensional reports, and process validation data that meet automotive PPAP criteria are examples of quality documentation.

Customer-Centric Service Approach

During the design stage, our engineering team works with clients to maximize casting geometry for cost-effectiveness and manufacturing feasibility. Through design changes, this proactive approach often finds ways to optimize material consumption, lower the need for machining, or improve product performance. Throughout the product lifetime, technical assistance is provided for design modifications and production scaling needs.

Reliable delivery dates are guaranteed for clients all across the globe thanks to global logistical capabilities. Customers may maximize their inventory management and production planning efforts with the help of our supply chain management tools, which provide real-time insight into production status and shipment timetables.

Conclusion

It is necessary to balance supplier skills and regional advantages with quality, cost, and delivery requirements when sourcing low pressure casting parts globally. Clearly establishing technical requirements, assessing suppliers using thorough standards, and fostering cooperative partnerships that support long-term goals are all essential for success. With North American timeliness, Asian efficiency, and European accuracy each meeting unique market demands, regional specialties provide clear benefits. To find the best partners, successful procurement strategies make use of industry networks, internet platforms, and direct supplier contact. Improved quality, lower prices, and increased supply chain dependability that supports competitive advantage in international markets are the results of investing in careful supplier assessment and relationship building.

FAQ

When choosing suppliers for low pressure casting, what certifications should I look for?

In addition to industry-specific standards like IATF 16949 for automotive applications and AS9100 for aerospace components, essential certifications include ISO 9001 for quality management systems. While NADCAP accreditation verifies specific procedures for military applications, environmental certifications like ISO 14001 show a dedication to sustainable manufacturing methods.

How long do bespoke low pressure casting orders usually take to process?

Lead times range from 6 to 12 weeks for the creation of new tools and from 3 to 6 weeks for production quantities utilizing pre-existing molds, depending on complexity and tooling needs. While high-volume production runs could need longer scheduling depending on capacity allocation, prototype quantities are often provided in two to four weeks.

Is it possible for low pressure casting to satisfy stringent automobile mechanical property requirements?

Compared to other casting techniques, low pressure casting excels at satisfying automotive mechanical property requirements because to its controlled solidification and decreased porosity. Excellent strength-to-weight ratios, fatigue resistance, and pressure tightness are produced by the method, making them ideal for crucial automotive applications like as structural parts and engine components.

How can I assess foreign vendors' quality capabilities?

Examining certificates, obtaining sample parts for metallurgical and dimensional analysis, and doing virtual or on-site factory audits are all important aspects of quality assessment. Examine their application of statistical process control, process controls, and measuring equipment calibration. Third-party audit reports and customer references provide further proof of skills.

What are low pressure casting's primary benefits over die casting?

By reducing turbulence during mold filling, lowering tooling costs for medium production quantities, and improving dimensional stability, low pressure casting provides outstanding mechanical qualities. The method produces products with superior surface smoothness and low porosity while doing away with the high clamping pressures needed in die casting.

Start Your Search for Reliable Low Pressure Casting Suppliers Today

Are you prepared to use precise low pressure casting technologies to maximize your component sourcing strategy? Fudebao Technology provides outstanding casting quality and dependability by fusing cutting-edge production capabilities with global supply chain knowledge. From the first design consultation until the delivery of the completed product, our integrated facility manages everything, guaranteeing dimensional correctness within tolerances of ±0.05mm. To explore your unique needs and learn how our low pressure casting manufacturing skills may improve your product performance while lowering total cost of ownership, get in touch with our engineering team at hank.shen@fdbcasting.com.

References

American Foundry Society. "Low Pressure Casting Technology and Applications in Modern Manufacturing." Foundry Management & Technology, 2023.

International Journal of Metalcasting. "Comparative Analysis of Low Pressure and Gravity Casting Methods for Aluminum Components." Springer Publishing, 2022.

Society of Manufacturing Engineers. "Global Sourcing Strategies for Precision Casting Components." Manufacturing Engineering Magazine, 2023.

Automotive Industry Action Group. "Supplier Quality Requirements for Casting Processes in Automotive Applications." AIAG Publications, 2022.

European Foundry Association. "Best Practices in Low Pressure Casting for Aerospace Applications." EFA Technical Report Series, 2023.

Materials Science and Engineering Institute. "Metallurgical Properties and Quality Control in Low Pressure Aluminum Casting." Academic Press International, 2022.

_1756346259673.webp)

_1756346613780.webp)

_1756350046757.webp)

_1756352625880.webp)