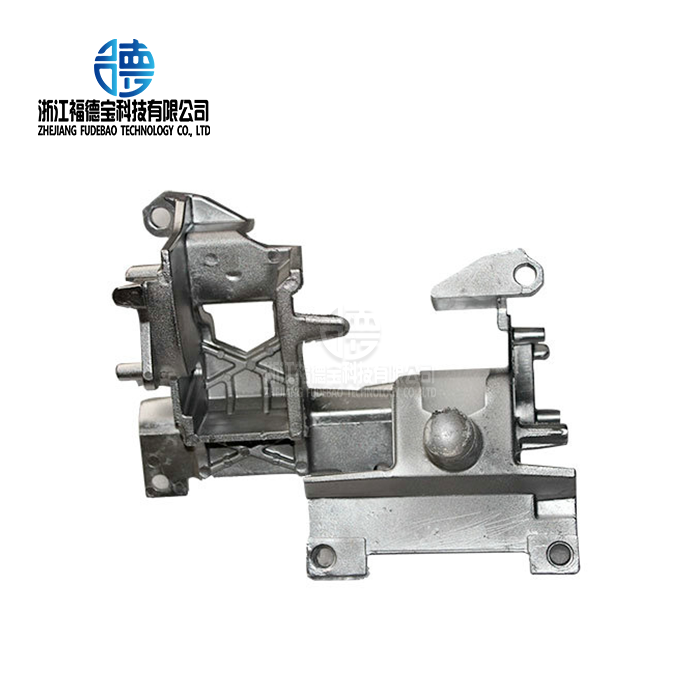

Heat sink aluminum casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Heat Sink Aluminum Casting: Precision-Engineered for Optimal Thermal Management

At Zhejiang Fudebao Technology Co., Ltd., we specialize in manufacturing high-quality heat sink aluminum castings. With 24 a long time of involvement, we've idealized our prepare to provide extraordinary warm administration arrangements. Our products offer prevalent warm scattering, vital for hardware, car, and mechanical applications. We pride ourselves on exactness, toughness, and cost-effectiveness.

Product Description

Our products are planned for ideal warm conductivity and effective warm dissemination. We utilize progressed low-pressure casting methods to guarantee uniform thickness and negligible porosity. This comes out in warm sinks that viably draw warm absent from basic components, improving by and large framework execution and life span.

Parameters

| Parameter | Specification |

|---|---|

| Material | ADC12, A356 Aluminum Alloy |

| Thermal Conductivity | 150-180 W/m·K |

| Surface Finish | Ra 1.6-3.2 μm |

| Dimensional Tolerance | ±0.05mm |

| Max Size | 500mm x 500mm x 300mm |

| Min Wall Thickness | 2.5mm |

Applications

- Power Electronics Cooling

- LED Lighting Systems

- Electric Vehicle Battery Management

- Computer and Server Components

- Industrial Motor Heat Dissipation

- Renewable Energy Inverters

Company Profile

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer of precision metal castings. Founded in 2001, we've grown from our roots in Hangzhou to our current 3000m² facility in Zhuji, Zhejiang. Our center on advancement, quality, and client fulfillment has made us a trusted accomplice for worldwide brands in car, mechanical gear, and vitality divisions. With advanced equipment and a skilled workforce, we deliver top-tier heat sink aluminum castings that meet the most demanding specifications.

Why Choose Us?

- 24 Years of Expertise in Precision Casting

- Advanced Equipment for Superior Quality

- Customization Capabilities

- Competitive Pricing

- On-Time Delivery

- Comprehensive Quality Control

Production Process

- Design and Mold Creation

- Material Selection and Preparation

- Low-Pressure Casting

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment (if required)

- Final Testing and Packaging

Certificates

- ISO 9001:2015

- IATF 16949

- RoHS Compliant

Packaging and Shipping

- Custom foam-lined boxes for protection

- Bulk packaging available for large orders

- Global shipping with tracking

FAQ

Q: What is the minimum order quantity for the products?

A: Our MOQ is typically 100 pieces, but we can accommodate smaller orders for prototyping or special requirements.

Q: Can you provide custom designs for heat sinks?

A: Yes, we offer full customization services. Our engineering team can work with your specifications to create optimal heat sink designs.

Q: What is the lead time for a typical order?

A: Standard lead time is 3-4 weeks, but this can vary based on order size and complexity. Rush orders may be accommodated upon request.

Q: Do you offer any surface treatments for the heat sinks?

A: We offer various surface treatments including anodizing, powder coating, and chemical film coating to enhance performance and aesthetics.

Contact Us

Ready to optimize your thermal management with our heat sink aluminum castings? Contact us today for a quote or to discuss your specific needs. Our team is ready to provide expert guidance and support.

Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology Co., Ltd. be your trusted partner for high-performance heat sink solutions. Experience the difference that precision engineering and quality manufacturing can make in your products' thermal management.

_1756350046757.webp)

_1756347888208.webp)

_1756348227989.webp)

_1756348711711.webp)

_1756349002499.webp)

_1756349794241.webp)

_1756349862928.webp)

_1756350092126.webp)