Top CNC Machining Companies for Custom Metal Parts

2026-01-21

Procurement professionals need partners that combine cutting-edge technology with shown dependability when looking for the best CNC machining businesses for bespoke metal parts. The foundation of contemporary manufacturing is CNC machining, which produces precision-engineered parts for the industrial equipment, automotive, aerospace, and energy industries. Leading businesses in this field set themselves apart with advanced machinery, accredited quality standards, and extensive service capabilities. These attributes are best shown by Fudebao Technology, which provides integrated solutions ranging from aluminum alloy casting to precision finishing with tolerances as low as ±0.05mm, providing reliable delivery performance and constant quality to worldwide companies.

Understanding CNC Machining and Its Industry Significance

Through automated production procedures, computer numerical control machining turns raw metal resources into precisely manufactured components. This advanced technology performs intricate cutting, milling, drilling, and turning operations with remarkable precision and reproducibility by using computer-controlled machine tools.

Fundamentals of Modern CNC Operations

Digital design files that direct multi-axis machine tools along predefined cutting routes are the first step in the operational process. To create complex designs from solid metal blocks, modern CNC centers use sophisticated spindles, tool changers, and workholding devices. Rapid material removal and strict dimensional tolerances are made possible by high-speed machining capabilities, which are crucial for precision mechanical parts, automobile housings, and aerospace structural elements.

Copper alloys for electrical conductivity, titanium for aeronautical needs, stainless steel for corrosive conditions, and aluminum alloys for lightweight automotive applications are among the materials that are often treated. To maximize surface smoothness and dimensional accuracy, different materials need different cutting settings, equipment choices, and cooling techniques.

Industry Reliance on Precision Manufacturing

CNC technology is crucial to the manufacturing sector's ability to produce components that adhere to strict performance criteria. Engine components and structural brackets with accurate mounting characteristics and uniform wall thickness are required by automotive OEMs. Manufacturers of industrial equipment need gearbox components and pump housings that can endure high working pressures. Manufacturers of electrical equipment need heat dissipation components with efficient thermal paths.

Compared to other production techniques, the technology has clear benefits. CNC machining offers better mechanical qualities and surface finishes appropriate for industrial applications than 3D printing. CNC techniques, in contrast to injection molding, allow for low-volume manufacturing runs without costly tooling expenditures. Because of these features, CNC machining is very useful for bespoke modifications, prototyping, and specific production needs.

Top CNC Machining Companies for Custom Metal Parts in 2026

A thorough assessment across many performance parameters is necessary when choosing trustworthy CNC machining partners. Prominent businesses exhibit excellence via their established quality processes, sophisticated production capabilities, and track records of satisfied customers.

Evaluation Criteria for Leading Providers

Operational excellence is fundamentally shown by quality certifications. While AS9100 certification verifies criteria unique to the aerospace industry, ISO 9001 standards guarantee uniform quality management methods. Compliance with the automobile sector is shown by IATF 16949 certification. Comprehensive process controls, documented processes, and continuous improvement approaches are shown in these certifications.

Manufacturing skills include technological know-how, capacity utilization, and sophisticated equipment. Multi-axis machining centers, automated workpiece handling, and integrated metrology systems are features of advanced facilities. Technical assistance is given by knowledgeable engineers and operators at every stage of the project's development, from the first design consultation to production optimization.

Reliable delivery performance, technical advising services, and prompt communication are all components of high-quality customer service. Prominent suppliers provide manufacturing process optimization, material advice, and design support. Throughout production cycles, they maintain open project tracking tools and provide frequent status reports.

Spotlight on Excellence: Fudebao Technology

Fudebao Technology has made a name for itself as a leading company in precision machining and aluminum foundry operations. The whole production cycle, from the melting of metal to the delivery of completed components, is covered by the company's integrated manufacturing method.

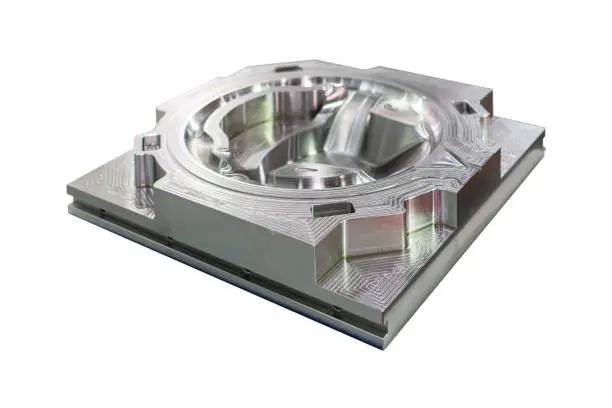

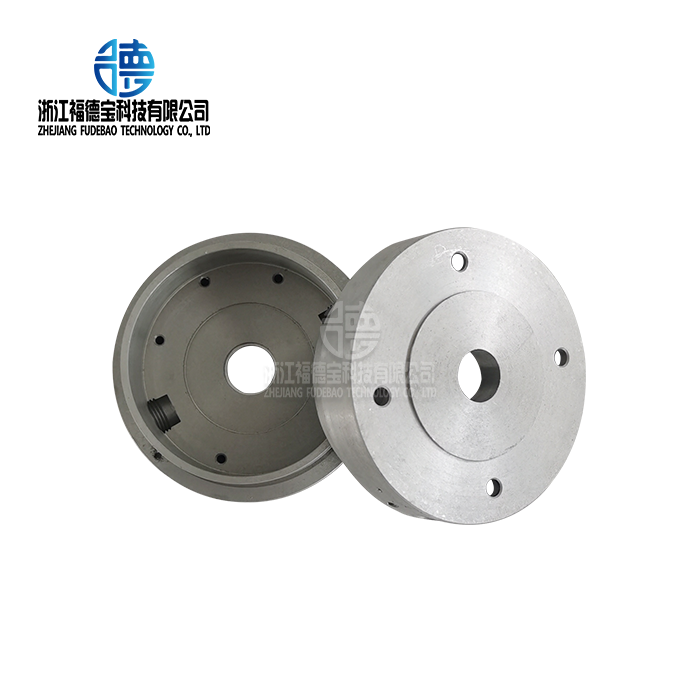

CNC lathes for rotating parts, high-speed machining centers for intricate geometries, and specialist casting equipment for copper and aluminum alloys are examples of core manufacturing skills. Under centralized quality control systems, the facility's extensive process coverage includes surface treatment, precision machining, melting, and casting activities.

Applications in the real world showcase the company's technological prowess in a variety of sectors. Precision engine parts with complex cooling channels and mounting brackets that need precise fitting criteria are used in automotive projects. Applications for industrial equipment include gearbox parts built for high-torque applications and pump housings with longer service lives. Projects in the electrical industry include connection assemblies that need accurate electrical contact surfaces and motor housings with enhanced heat dissipation characteristics.

How to Choose the Right CNC Machining Partner for Your Custom Metal Parts?

Project criteria and supplier capabilities must be carefully aligned when making procurement selections. Thorough assessment of technical specifications, manufacturing limitations, and long-term corporate goals is essential for successful collaborations.

Aligning Project Requirements with Supplier Capabilities

Component complexity affects supplier selection criteria and pushes machining needs. While complicated interior features and curves need multi-axis capability, simple geometric features may handle ordinary three-axis equipment. Basic machined finishes, precision-ground surfaces for sealing applications, and ornamental treatments for exposed components are all examples of surface finish needs.

Strategies for cost optimization and manufacturing methods are impacted by production volume issues. Flexible setup processes and quick switching capabilities are advantageous for low-volume needs. Dedicated fixturing and optimal cutting settings are used in medium-volume manufacturing. Automated handling systems and specialized tools are justified by high volume applications.

Expectations for delivery timelines must be in accordance with workflow management and supplier capability. Fast material procurement and adequate machine time are necessary for urgent tasks. Optimal production scheduling and quality assurance processes are made possible by standard timeframes. Investments in process improvement and capacity allocation are made possible by long-term partnerships.

Evaluating Cost Structures and Value Propositions

A thorough cost analysis takes into account the overall project economics in addition to unit pricing. Budgets for the whole project are impacted by setup fees, tooling expenses, and material surcharges. Considerations for the overall delivered cost include value-added services like design optimization, material certification, and packaging solutions.

Lead time commitments for CNC machining affect production planning flexibility and inventory needs. Reputable vendors have consistent performance records and provide precise delivery predictions. Suppliers are able to adapt to changing needs and provide backup assistance when necessary thanks to advanced planning capabilities.

Both present project success and future capacity needs are impacted by technological complexity. Complex programming and simulation capabilities made possible by advanced CNC software save development times and increase first-article success rates. Modern metrology equipment delivers statistical process control data and guarantees dimensional conformity.

Innovations and Precision Techniques in CNC Machining

Precision machining skills and quality assurance techniques are being revolutionized by advanced industrial technology. Tighter tolerances, better surface finishes, and increased manufacturing efficiency in a variety of applications are made possible by these developments.

Advanced Software Solutions and Process Controls

Sophisticated toolpath optimization algorithms are integrated into modern CNC programming software to maximize material removal rates while minimizing cutting pressures. Advanced simulation capabilities offered by CAM systems such as Siemens NX and Mastercam ensure program correctness prior to production execution. Automated collision detection, adaptive cutting methods, and sophisticated multi-axis operations are made possible by these instruments.

Quality assurance techniques utilize statistical process control methodologies and real-time monitoring systems. Dimensional verification with sub-micron precision is offered by coordinate measuring devices. Dimensional drift correction and automated tool wear adjustment are made possible by in-process gauging systems. Throughout manufacturing runs, these technologies guarantee constant component quality.

Advanced machine operation, programming methods, and quality control protocols are the main topics of operator training programs. Certified technicians are knowledgeable in cutting tool selection, material qualities, and troubleshooting techniques. Operators stay up to date on new advancements in best practices and technology via ongoing education.

Material Selection and Design Optimization Strategies

Cost optimization, component functioning, and machining performance are all greatly impacted by material choice. Aluminum alloys are perfect for automotive and aerospace applications because of their exceptional machinability and lightweight nature. Grades of stainless steel provide industrial equipment mechanical strength and resistance to corrosion. Certain qualities, like as thermal conductivity for heat dissipation purposes, are provided by specialized alloys.

Manufacturability enhancements that lower production complexity while preserving functional requirements are the core focus of design optimization approaches. Machining procedures are made simpler by characteristics including consistent wall thickness, sufficient corner radii, and easily accessible tool clearances. Cutting pressures and cycle durations are minimized by strategic material removal patterns. Both component quality and manufacturing efficiency are directly impacted by these factors.

Cutting speed, feed rate, and depth of cut variables are used in process parameter optimization to increase output while preserving quality requirements. Coated carbide inserts and customized geometries are examples of advanced tooling technologies that increase tool life and enhance surface finish quality. Chip evacuation and heat management during high-speed operations are impacted by coolant selection and application techniques.

Fudebao Technology Overview

Aluminum alloy, copper alloy, and stainless steel casting along with CNC machining services are the areas of expertise for Zhejiang Fudebao Technology Co., Ltd., a full solution supplier. Regional supplier links have given way to direct agreements with global companies, such as American HAAS automation systems and ESS energy storage applications.

Core Competencies and Manufacturing Excellence

The manufacturing infrastructure of the organization comprises integrated capabilities that cover the whole production cycle. Precision CNC lathes for rotating components, die casting equipment for high-volume applications, low-pressure casting machines for aluminum components, and high-speed machining centers capable of intricate multi-axis operations are examples of core equipment. From simple cleaning to specialty coatings, surface treatment technologies provide a wide range of finishing possibilities.

In order to satisfy the strict criteria for medical equipment housings and automotive precision components, quality control systems maintain dimensional accuracy levels as high as ±0.05mm. Comprehensive inspection capabilities are offered throughout manufacturing processes by state-of-the-art metrology equipment. Methodologies for statistical process control provide consistent quality delivery across a range of production quantities.

By combining casting, machining, and finishing activities under a single management, the integrated method removes the difficulties associated with conventional supply chains. For complicated projects involving many manufacturing processes, this coordination offers single-source responsibility, shorter lead times, and improved quality consistency.

Comprehensive Service Portfolio

Design consulting services that maximize component manufacturability while upholding functional criteria are part of product development assistance. Customers and engineering teams work together from the first stages of idea creation to the stages of production optimization. Guidance on material selection aids in determining the best alloys for a given application's needs.

Various volume needs, from prototype amounts to production runs, are accommodated by production flexibility. Fast functional testing and design verification are made possible by rapid prototyping capabilities. Phases of market launch and specialized applications are supported by low-volume manufacture. Growing production needs are handled with scalable capacity without sacrificing quality standards.

From the acquisition of materials to the delivery of completed components, logistical solutions provide complete project management. Coordination of international shipment guarantees dependable delivery to client locations worldwide. Seasonal demand fluctuations and just-in-time delivery needs are supported by inventory management services. Fudebao Technology is positioned as a strategic partner rather than just a seller of components because to their extensive capabilities.

Conclusion

Due to advancements in technology and rising standards for quality in the automotive, industrial, electrical, and aerospace industries, the field of CNC machining for bespoke metal parts is constantly changing. Prominent businesses set themselves apart with innovative production skills, verified quality systems, and extensive customer support services. Partners that combine technical know-how, dependable delivery performance, and adaptable capacity management are advantageous to procurement experts. Fudebao Technology's precise quality control, integrated production capabilities, and dedication to client success across a range of industrial applications are examples of these attributes.

FAQ

What elements affect custom metal part lead times for CNC machining?

Component complexity, material availability, manufacturing volume, and existing facility capacity utilization are all factors that affect lead time. Longer setup periods are usually required for complex geometries that demand for multi-axis operations and specialized tools. Compared to specialty alloys that need verified mill test certifications, standard materials like aluminum alloys have faster procurement periods. Dedicated manufacturing runs that shorten cycle durations per item but have longer overall scheduling windows may be justified by higher quantities.

What is the cost-effectiveness of CNC machining in comparison to other production techniques?

Production volume, component complexity, and quality standards all have a significant impact on cost comparisons. For low to medium quantities, when injection molding tooling prices become unaffordable, CNC machining provides benefits. When compared to additive manufacturing techniques, the technology offers better mechanical qualities and surface finishes. Unit prices become more advantageous as quantities rise since setup expenses are essentially constant regardless of volume. The ability to adapt to design alterations without changing the tools adds value to development initiatives.

Which certifications attest to the dependability and quality standards of CNC machining suppliers?

The adoption of a basic quality management system and continuous improvement techniques are shown by ISO 9001 accreditation. Aerospace-specific standards including traceability, configuration control, and risk management are validated by AS9100 certification. The automobile industry's adherence to statistical process control and production part approval procedures is verified by IATF 16949 certification. Specialized criteria are further validated by industry-specific certifications, such as NADCAP accreditation for aeronautical applications or FDA registration for medical components.

Partner with Fudebao Technology for Superior CNC Machining Solutions

Find out how the sophisticated CNC machining skills of Fudebao Technology can maximize your needs for producing unique metal components. Precision casting and cutting-edge machining technologies are used in our integrated production strategy to produce components that satisfy the most exacting requirements. We have shown expertise working with industrial equipment makers, automotive OEMs, and aerospace applications, and we know how crucial dimensional precision, delivery dependability, and quality consistency are. To discuss your unique project needs and find out how our extensive skills may help you achieve your procurement goals, get in touch with hank.shen@fdbcasting.com.

References

"Advanced CNC Machining Technologies for Precision Manufacturing Applications" - American Society of Mechanical Engineers Technical Publication, 2024

"Quality Standards and Certification Requirements in Modern CNC Manufacturing" - International Organization for Standardization Guidelines, 2023

"Material Selection and Optimization Strategies for Custom Metal Components" - Materials Science and Engineering Journal, 2024

"Cost Analysis and Procurement Best Practices for CNC Machining Services" - Institute of Supply Management Research Report, 2023

"Industry 4.0 Integration in Computer Numerical Control Manufacturing Systems" - Manufacturing Technology Review, 2024

"Global Trends and Market Analysis in Custom Metal Parts Manufacturing" - Industrial Manufacturing Research Institute, 2023

_1756346259673.webp)

_1756346668222.webp)

_1756361323684.webp)