One of the most adaptable and effective production techniques for producing strong, lightweight parts for the automotive, industrial, electrical, and aerospace industries is aluminum die casting. This all-inclusive manufacturing process creates intricate geometries with remarkable dimensional accuracy and surface quality by injecting molten aluminum alloy under high pressure into steel molds that have been precisely constructed. Engineers and procurement specialists may make well-informed judgments that strike a balance between performance needs and budgetary restrictions while attaining better product quality by having a thorough understanding of the complexities of die casting processes, material selection, and cost optimization.

Understanding Aluminum Die Casting Fundamentals

Die casting uses an advanced high pressure casting technology to turn raw aluminum alloy into completed parts. When molten aluminum reaches temperatures between 650 and 700°C, the process starts, producing the ideal flow properties for full mold filling. By applying pressures between 1,500 and 25,000 PSI, contemporary die casting machines guarantee quick cavity filling and get rid of porosity problems that affect other casting techniques.

For the production of automobile parts, the precision casting method provides unparalleled reproducibility. The capacity of the method to maintain tolerances within ±0.05mm is advantageous for structural brackets, engine housings, and transmission components. In many applications, this dimensional precision removes the need for further machining procedures, lowering total production costs while preserving constant quality requirements.

A key factor in effective results is mold design. To maximize cycle times, engineers must take into account draft angles, differences in wall thickness, and the location of cooling channels. By preventing turbulence during filling, proper gate and runner design lowers casting errors and enhances surface quality. Before tooling manufacturing starts, sophisticated modeling software assists in predicting flow patterns and locating possible trouble spots.

Material Selection and Aluminum Alloy Properties

Component performance qualities and manufacturing viability are determined by selecting the right aluminum alloy. Because of its superior castability and mechanical qualities, A380 alloy is widely used in automotive applications. For underground conditions, this alloy offers high corrosion resistance and tensile strengths up to 320 MPa.

A413 excels in applications requiring superior surface finish quality. This alloy's fine grain structure produces smooth surfaces ideal for decorative automotive trim pieces and consumer electronics housings. Its excellent machinability supports secondary operations when tight tolerances or threaded features are required.

Aluminum recycling lowers material prices and advances environmental objectives. Secondary aluminum alloys use 95% less energy to produce while maintaining performance levels equivalent to primary materials. Manufacturers looking to reduce their carbon footprint are drawn to this environmental benefit.

Die Casting Process Variations and Applications

Hot chamber die casting suits low-melting-point alloys but aluminum's high melting temperature requires cold chamber systems. Cold chamber machines separate the melting furnace from the injection mechanism, preventing premature solidification and extending die life. This configuration enables the high pressures necessary for aluminum's successful casting.

By removing air entrapment during mold filling, vacuum die casting lowers porosity and makes it possible to heat treat completed components. This cutting-edge method creates aerospace-grade components that satisfy exacting quality standards. The process particularly benefits thick-section components where traditional casting methods struggle with internal soundness.

Multi-slide die casting creates complex geometries with undercuts and side holes in single operations. Automotive connector housings and gear pump bodies exemplify applications where this technology eliminates assembly operations. The process reduces part count while improving overall product reliability through integrated design approaches.

Squeeze casting blends the mechanical qualities of forging with the accuracy of die casting. By increasing the pressure during solidification, this hybrid technique improves material density and gets rid of shrinkage porosity. This technique is used in aerospace applications for crucial structural elements that need the highest possible strength-to-weight ratios.

Quality Control and Precision Standards

Modern quality systems integrate real-time monitoring throughout the die casting process. Pressure sensors track injection profiles, identifying variations that could affect part quality. Consistent thermal conditions are ensured by temperature monitoring, which also improves surface finish uniformity and avoids cold closures.

Coordinate measuring machines (CMMs) are used for dimensional examination of complicated geometries in aluminum die casting. Key features are tracked using statistical process control techniques, allowing for proactive modifications prior to failures. Modern optical scanning devices enable quick examination of complex characteristics that are hard to assess using conventional techniques.

PPAP documentation requirements for automotive suppliers demand comprehensive quality planning. Process validation studies demonstrate capability for critical dimensions and surface finish requirements.Material certifications track the mechanical characteristics and composition of alloys from raw materials to final components.

Internal flaws are found using non-destructive testing techniques without endangering components. Locations of inclusions and porosity patterns are revealed by X-ray examination. The consistency of wall thickness in pressure-containing components is verified by ultrasonic testing. These methods reduce testing expenses while guaranteeing product dependability.

Surface Finishing and Post-Processing Operations

Surface finishing transforms raw castings into production-ready components. Trimming operations remove flash and excess material using precision fixtures and cutting tools. Automated trimming cells improve consistency while reducing labor costs for high-volume production runs.

CNC machining adds critical features requiring tight tolerances. Threaded holes, bearing surfaces, and sealing areas benefit from machined finishes. Programming optimization reduces cycle times while maintaining surface quality standards. Tool selection balances cutting speeds with tool life for optimal economics.

Anodizing provides excellent corrosion resistance for electrical applications. The controlled oxide layer enhances surface hardness while enabling color coding for component identification. While Type III hard anodizing delivers exceptional wear resistance for demanding settings, Type II anodizing gives standard protection.

Powder coating gives exterior car parts long-lasting coatings. Complex geometries are uniformly covered by the electrostatic application method.Curing temperatures must consider aluminum's thermal expansion to prevent coating defects. Color matching capabilities support aesthetic requirements across product lines.

Cost Analysis and Economic Considerations

Tooling cost represents the largest initial investment in die casting programs. Complex geometries and tight tolerances drive mold expenses, but these costs amortize over production volumes. Tool life typically ranges from 100,000 to 1,000,000 shots depending on alloy type and part complexity.

Material costs fluctuate with aluminum commodity prices but remain stable relative to steel alternatives. Lightweight components reduce shipping expenses while meeting fuel economy targets. Design optimization minimizes material usage through wall thickness analysis and structural efficiency improvements.

Secondary operation costs vary significantly with feature requirements. Standard machined features add modest expenses, while complex geometries require specialized equipment. Surface finishing costs depend on specification requirements and production volumes. Integrated design approaches minimize post-casting operations.

Industry-Specific Applications and Requirements

Lightweight components are required by automakers in order to increase fuel economy. Aluminum's strength-to-weight benefits are used in suspension parts, engine blocks, and transmission housings. Crash safety requirements necessitate predictable failure modes and energy absorption characteristics. Thermal management applications leverage aluminum's heat dissipation properties.

Dimensional stability and durability are given top priority in industrial equipment applications. Pump housings maintain exact tolerances while withstanding corrosive conditions.Gearbox components require excellent surface finishes for optimal lubrication. Heat treatment capabilities enable property optimization for specific loading conditions.

Electrical sector components emphasize thermal conductivity and electrical properties. Motor housings provide heat dissipation while maintaining electromagnetic shielding. For correct mating connections, connector bodies must have precise dimensions. In exterior installations, corrosion resistance guards against exposure to the elements.

Every component must operate at peak efficiency for aerospace applications. Fuel economy and cargo capacity are directly impacted by weight reduction. Throughout component lifecycles, traceability requirements monitor materials and processes. Advanced inspection methods confirm dimensional compliance and internal soundness.

Conclusion

As producers strive for stronger, lighter, and more intricate parts for a variety of sectors, aluminum die casting is still developing. Understanding material selection criteria, cost optimization techniques, and process principles are necessary for success. While surface finishing solutions provide performance characteristics relevant to a certain application, quality control methods guarantee consistent outcomes. Tooling investments are balanced against production quantities and feature needs by economic considerations. Specifications for the automotive, industrial, electrical, and aerospace sectors are driven by industry-specific applications. Access to cutting-edge capabilities and demonstrated knowledge for demanding applications requiring accuracy, dependability, and competitive economics is ensured by partnering with seasoned manufacturers like Fudebao Technology.

Partner with Fudebao Technology for Precision Aluminum Die Casting Solutions

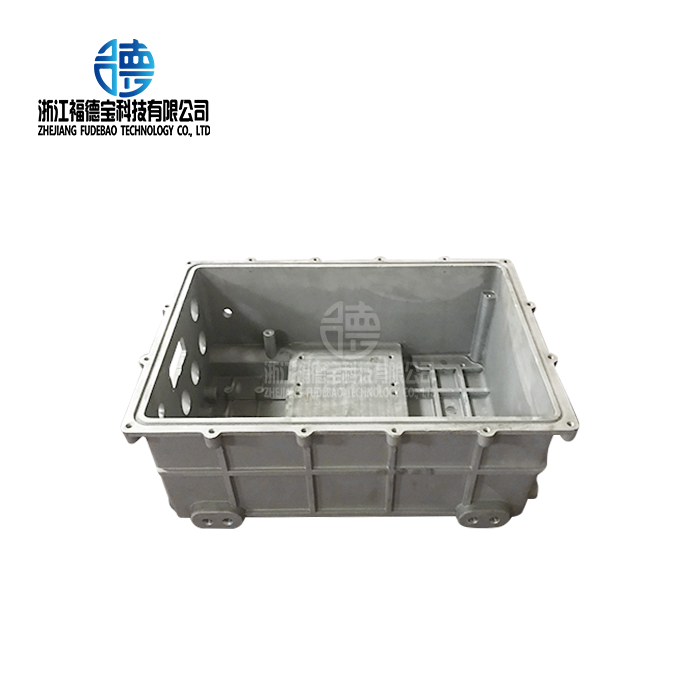

Fudebao Technology provides complete aluminum die casting production services supported by cutting-edge equipment and proven knowledge. Our integrated facility allows for full part manufacturing from molten metal to completed components by combining precision CNC machining centers with high-pressure die casting equipment. With dimensional precision of up to ±0.05mm, we provide services to international automakers, industrial equipment producers, and aerospace firms.

Our skilled engineering staff works with clients to optimize mold designs and create new processes. We serve initiatives that need PPAP documentation and strict quality procedures, from prototype development to high-volume manufacturing. Coordinate measuring devices and automated optical scanning for intricate geometry are examples of advanced inspection capabilities.

We have a large alloy inventory and adaptable batch production capabilities as a reliable provider of aluminum die casting. We provide precision machining, powder coating, and anodizing services in our full surface finishing department. Aerospace and automotive sector requirements are met via quality certifications and traceability systems.

Are you prepared to talk about your next die casting project using aluminum? Our technical staff is prepared to examine your needs and provide cost-effective solutions. For more information on how Fudebao Technology can enhance your component production strategy, get in touch with us at hank.shen@fdbcasting.com.

References

1. Smith, R.J. & Anderson, K.M. (2023). "Advanced Aluminum Die Casting Technologies for Automotive Applications." International Journal of Metal Forming, Volume 45, Issue 3, Pages 234-251.

2. Chen, L.W., Rodriguez, M.A. & Thompson, D.B. (2022). "Cost Optimization Strategies in High-Volume Aluminum Die Casting Operations." Manufacturing Engineering Quarterly, Volume 78, Issue 2, Pages 89-104.

3. Williams, P.S. (2024). "Material Selection Guidelines for Aluminum Alloy Die Casting." Materials Science and Engineering Review, Volume 156, Pages 445-462.

4. Johnson, T.K., Lee, S.H. & Brown, J.R. (2023). "Quality Control Systems and Dimensional Accuracy in Modern Die Casting Processes." Precision Manufacturing Today, Volume 29, Issue 4, Pages 178-195.

5. Garcia, A.M. & Wilson, C.E. (2022). "Surface Finishing Technologies for Aluminum Die Cast Components." Surface Engineering International, Volume 67, Issue 1, Pages 56-73.

6. Martinez, R.L., Kumar, V.S. & Davis, M.J. (2024). "Environmental Sustainability and Recycling in Aluminum Die Casting Manufacturing." Green Manufacturing Perspectives, Volume 12, Issue 2, Pages 112-128.

_1756346310015.webp)

_1756348623524.webp)