Knowing the basic distinctions between die casting and sand casting is essential for project success when choosing the best production method for metal components. While sand casting gives unparalleled flexibility for complicated geometries and low to medium production runs, die casting performs very well in high-volume production situations demanding outstanding dimensional precision and superior surface polish. Your unique needs, such as part complexity, manufacturing volume, dimensional tolerances, material qualities, and financial restraints, will ultimately determine the choice. In automotive, industrial machinery, electrical equipment, and aerospace applications, both techniques provide clear benefits.

Understanding Die Casting Fundamentals

A precise manufacturing technique called die casting involves injecting molten metal under high pressure into steel molds. With tolerances of ±0.05mm, this method produces components with remarkable dimensional precision. This method is perfect for high-volume manufacturing needs since the steel dies can endure thousands of cycles.

Melted aluminum, zinc, or magnesium alloys are forced into complex mold cavities by modern die casting machines, which run at pressures between 1,500 to 25,400 psi. This process's natural quick cooling rate creates fine grain structures, which improve mechanical qualities and smooth surface finishes, often doing away with the need for further machining.

Die casting is especially valued by automakers for structural brackets, engine housings, and transmission cases where exact measurements and lightweight materials are crucial. Thin-walled portions and intricate interior features that would be difficult to accomplish using conventional machining techniques are supported by the procedure.

Exploring Sand Casting Capabilities

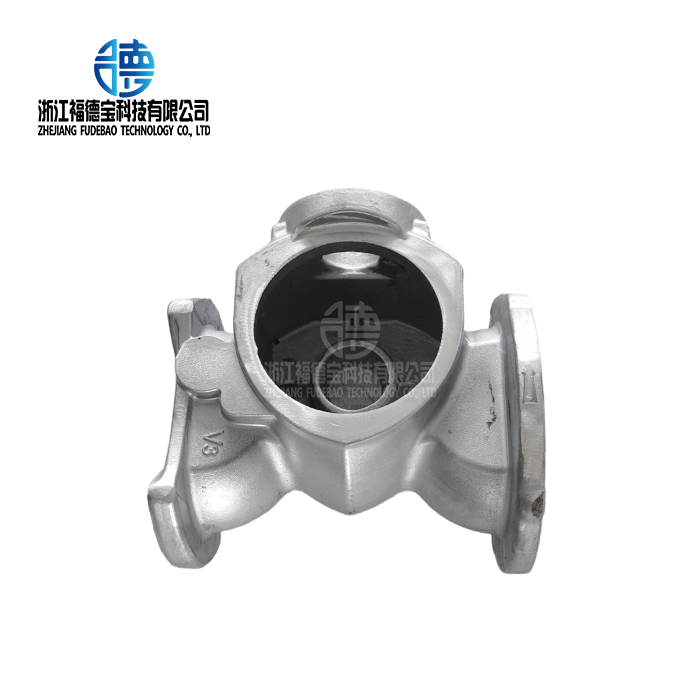

To make metal parts, sand casting uses disposable sand molds made around designs. With the use of cores and sophisticated gating mechanisms, this foundry technology can support almost infinite part sizes and complicated interior geometries. More design freedom is possible since, in contrast to permanent mold techniques, each sand mold is destroyed following portion extraction.

To obtain the right permeability and strength qualities, the molding sand combination usually includes silica sand, clay binders, and moisture. Although resin-bonded sands provide better structural stability for certain applications, green sand systems are still the most often used method.

For pump housings, valve bodies, and gearbox components where material strength and heat resistance are more important than surface polish, industrial equipment manufacturers mostly depend on sand casting. Alloys made of copper, steel, aluminum, and cast iron may be easily included into the process with little tooling.

Production Volume Considerations

Production volume significantly influences the optimal casting selection. Die casting becomes cost-effective at quantities more than 1,000 pieces per year, justifying its higher tooling costs via economies of scale. The permanent steel dies retain constant quality while spreading their cost across thousands of pieces.

Sand casting, on the other hand, works well in low to medium volume situations for prototype development. It is economically feasible for numbers ranging from single prototypes to several thousand units per year since pattern costs are still rather low as compared to die casting tooling.

The complexity of the part and the dimensional constraints affect the breakeven point. While complicated components with considerable coring needs often make sand casting more cost-effective even at greater production levels, simple geometries may benefit die casting at lower volumes.

Material Properties and Performance

The performance of components is influenced by the unique material properties imparted by each casting process. The quick solidification of die casting produces fine-grained microstructures with improved mechanical qualities. Superior tensile strength and fatigue resistance are produced by the rapid cooling rate, which also reduces porosity.

Controlled cooling rates that may be tailored for certain material qualities are made possible by sand casting. Stress may be reduced and heat treatment procedures can be more successfully implemented due to the delayed solidification. This becomes particularly important for applications requiring maximum ductility or specific hardness characteristics.

These distinctions are often strategically used in aerospace applications. Larger assemblies benefit from sand casting's capacity to create stress-relieved components with predictable material characteristics, while critical structural components may use die casting for optimal strength-to-weight ratios.

Dimensional Accuracy and Surface Quality

These manufacturing techniques differ greatly in dimensional accuracy. For most features, die casting regularly reaches tolerances of ±0.1mm, with specialized applications achieving ±0.05mm precision. Throughout lengthy production runs, the steel dies retain their dimensions, guaranteeing reliable part-to-part reproducibility.

Sand casting usually yields tolerances between ±0.5mm and ±1.5mm, dependent on the complexity and size of the item. These tolerances often prove sufficient for many industrial applications, even if they are wider than die casting capabilities. This is especially true when taking into account the geometric flexibility of the process.

The grade of the surface polish varies significantly as well. Die cast parts have smooth surfaces and need little finishing work. The sand grain structure is reflected in the rougher surface textures of sand cast items, which often need for machining for sealing or crucial areas.

Tooling Investment and Lead Times

Initial tooling requirements present substantial differences between these processes. Die casting demands precision-machined steel dies costing tens of thousands of dollars and requiring 8-16 weeks for completion. However, these tools can produce hundreds of thousands of parts with proper maintenance.

Sand casting patterns can be manufactured from wood, aluminum, or composite materials at significantly lower costs. Simple patterns may be completed within days, while complex assemblies require several weeks. This rapid tooling capability makes sand casting ideal for urgent prototype needs or market testing scenarios.

The ability to modify sand casting patterns relatively easily provides additional flexibility during product development phases.Pattern or core alterations may typically support design changes that would otherwise need costly die revisions.

Industry-Specific Applications

Die casting is often specified by automakers for body structure elements, suspension components, and engine components where surface quality and dimensional precision are crucial. The lightweight aluminum alloys help achieve fuel economy goals, and die casting's economic model is ideal for the large volume needs of the car sector.

Sand casting is often preferred for heavy equipment components, pumps, and compressors in industrial machinery applications. Large, intricate forms may be cast in a variety of alloys, which makes this method essential for producing specialized gear.Heat resistance and material strength often outweigh surface finish considerations in these applications.

Electrical equipment manufacturers utilize both processes strategically. While transformer cases and large switchgear components often depend on sand casting for the economical manufacturing of complicated geometries, motor housings and electrical enclosures may use die casting for EMI shielding and exact fit requirements.

Quality Control and Inspection

Quality assurance approaches differ between these manufacturing processes due to their inherent characteristics. Die casting operations implement statistical process control monitoring die temperature, injection pressure, and cycle times to maintain consistent quality. Real-time quality feedback and automated inspection systems are made possible by the process's repeatability.

Molding sand characteristics, pattern precision, and pouring methods are the main areas of concern for sand casting quality control. Every mold is a distinct manufacturing example that needs meticulous attention to the processes of metal pouring, core placement, and sand preparation. Prior to the final examination, non-destructive testing techniques such as X-ray inspection aid in locating interior flaws.

Advanced inspection technologies, such as coordinate measuring devices and 3D scanning systems, are advantageous to both procedures. However, more advanced measuring tools and methods are often required to achieve the finer tolerances made possible by die casting.

Environmental and Sustainability Factors

Environmental factors are becoming more and more important when choosing a manufacturing technique. Because of the high-pressure injection systems and controlled die temperatures, die casting processes usually use more energy. Nonetheless, the process' accuracy reduces material waste and often does away with subsequent activities.

Excellent recyclability properties are shown by sand casting, since molding sand may be recycled through many cycles with appropriate reconditioning. Reduced environmental effect is a result of the decreased energy needs for mold preparation and pattern manufacturing, especially in low-volume production settings.

Aluminum recycling programs are supported by both procedures, and foundries often use significant quantities of recycled material. The whole lifecycle effect, including transportation, secondary operations, and end-of-life recyclability, should be taken into account when selecting a method.

Conclusion

The decision between die casting and sand casting ultimately comes down to the demands of your particular project, production levels, and quality standards. While sand casting offers unparalleled flexibility for complicated geometries and economical low to medium volume manufacturing, die casting is best suited for high-volume applications requiring great dimensional precision and surface polish. When selecting this crucial manufacturing choice, take into account elements including component complexity, material requirements, dimensional tolerances, surface quality requirements, and overall project costs. Both procedures have unique benefits that, when appropriately matched to the needs of the application, provide the best outcomes for components used in automotive, industrial, electrical, and aerospace applications.

Choose Fudebao Technology as Your Trusted Sand Casting Supplier

Regardless of the method you use, choosing the correct production partner guarantees that your casting project will provide the best results. Fudebao Technology offers comprehensive solutions for automotive, industrial, electrical, and aerospace applications by fusing precision machining services with cutting-edge die casting and sand casting capabilities.

The whole production process, from melting to surface treatment, is supported by the high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment housed at our facility. With accuracy up to ±0.05mm, this all-inclusive capability allows for one-stop delivery from blank to completed product.

We recognize that dependable collaborations supported by demonstrated competencies and certifications are essential for engineering managers, sourcing directors, and quality teams. Our dedication to quality and dependability is shown by our expertise working with global companies, such as American HAAS automation and ESS energy storage.

Our technical staff offers professional assistance throughout the selection and production process, regardless of whether your project requires flexible sand casting for industrial equipment components or high-volume die casting for automotive precision parts. To discuss your unique needs and find out how our casting experience can maximize your next project, get in touch with us at hank.shen@fdbcasting.com.

References

1. Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Second Edition. Butterworth-Heinemann, 2015.

2. Groover, Mikell P. "Fundamentals of Modern Manufacturing: Materials, Processes, and Systems." Seventh Edition. John Wiley & Sons, 2020.

3. Viswanathan, S., et al. "An Overview of Metal Casting Processes and Their Applications in Automotive Industry." Journal of Manufacturing Processes, Vol. 45, 2019.

4. Brown, John R. "Foseco Ferrous Foundryman's Handbook." Eleventh Edition. Butterworth-Heinemann, 2000.

5. Beeley, Peter R. "Foundry Technology." Second Edition. Butterworth-Heinemann, 2001.

6. Davis, Joseph R. "ASM Specialty Handbook: Cast Irons." ASM International Materials Park, 1996.

_1756349071334.webp)

_1756349957728.webp)

_1756352340434.webp)