Optimizing CNC machining for mass production requires strategic planning, advanced programming techniques, and efficient workflow management. The key lies in standardizing toolpaths, implementing automated systems, minimizing setup times, and maintaining consistent quality control throughout the production cycle. Successful CNC machining operations leverage CAD/CAM integration, fixture design optimization, and cutting tool standardization to achieve maximum throughput while maintaining precise tolerances and superior surface finishes.

Why CNC Machining Optimization Matters in Today's Manufacturing Landscape?

Cost-effectiveness and production efficiency are key factors in manufacturing competitiveness. Manufacturers of industrial equipment, aerospace firms, and automobile OEMs now have more stringent deadlines and larger volume requirements than in the past. Conventional machining techniques often fail when going from prototype to mass manufacturing.

When working with precision components that need an accuracy of ±0.05mm, the problem becomes much more complicated. Sourcing directors and engineering managers are always looking for suppliers that can maintain low price while producing thousands of components with consistent quality. Because of this fact, complex optimization techniques are required to turn routine CNC operations into very effective production systems.

Optimizing advanced machining has a direct influence on cycle times, material use, and overall machine performance. Businesses that use these tactics usually see 30–40% increases in throughput while cutting waste and rework expenses. Precision machining combined with automation produces long-term competitive advantages in international marketplaces.

Essential Selection Criteria for Mass Production CNC Optimization

Evaluating optimization strategies requires understanding specific performance metrics that impact mass production success. Our study focuses on tried-and-true techniques that provide quantifiable outcomes in a variety of production volumes and sectors.

Cycle time reduction possibilities, setup standardization capabilities, quality consistency measurements, and scalability across various component geometries are important assessment factors. Timelines for return on investment, training needs, and implementation difficulty are all taken into account. These elements guarantee that suggested tactics are in line with actual production limitations and corporate goals.

Solutions that are compatible with different CNC controller systems and machine tool setups are prioritized throughout the selection process. Integration with quality management systems and compatibility with current CAD/CAM processes continue to be crucial factors. Each recommended approach has been validated through actual production environments serving automotive, industrial machinery, and aerospace applications.

Advanced Toolpath Programming and G-code Optimization

Workflows for efficient mass manufacturing are built on top of sophisticated programming methods. Complex toolpath techniques that significantly save machining times while enhancing surface quality and tool life are made possible by modern CAD/CAM systems.

By using adaptive toolpaths and optimal cutting settings, high-speed machining principles transform material removal rates.These strategies maintain constant chip loads while minimizing heat generation and tool wear. The result achieves 25-35% faster cycle times compared to conventional programming approaches.

Adaptive clearing algorithms automatically adjust cutting parameters based on material engagement calculations. This intelligence prevents tool overload while maximizing material removal rates in varying stock conditions. The technology proves especially valuable for casting finishing operations where stock variations are common.

3-axis machining optimization focuses on efficient tool change sequences and minimized air cutting time. Strategic programming combines multiple operations using single tool setups, reducing non-productive time by 40-50%. This approach works exceptionally well for bracket and housing components requiring multiple features.

5-axis machining strategies eliminate multiple setups through complete part finishing in single operations. Advanced simultaneous machining reduces cycle times while improving geometric accuracy through consistent workpiece positioning. The technique particularly benefits complex engine components and structural aerospace parts requiring tight tolerance maintenance.

Automated Fixture Design and Workholding Solutions

Standardized workholding systems create consistent setup procedures that minimize human error while reducing changeover times. Advanced fixture design incorporates modular components that adapt to part family variations without complete reconfiguration.

Pneumatic and hydraulic clamping systems provide repeatable positioning accuracy while enabling rapid part loading cycles. These systems typically achieve setup time reductions of 60-70% compared to manual clamping methods. The consistency improves overall part quality through eliminated setup variations.

Tombstone fixtures maximize machine utilization through simultaneous multi-part processing. Strategic part orientation enables complete machining operations while subsequent parts undergo loading procedures. This approach effectively doubles production capacity on existing equipment.

Automatic part loading systems integrate with robotic handling equipment for lights-out manufacturing capabilities. These installations enable continuous production during unmanned shifts while maintaining quality standards. The technology proves especially valuable for high-volume automotive components requiring 24-hour production schedules.

Precision indexing systems allow complex part geometries to be machined from multiple angles without repositioning accuracy loss. Advanced encoders maintain angular positioning within 0.001-degree precision, ensuring consistent feature relationships across production volumes.

Quick-change palletized systems enable setup preparation during productive machining cycles. Operators prepare subsequent jobs while machines continue processing, effectively eliminating setup downtime. This strategy works particularly well for mixed production environments serving multiple customer requirements.

Cutting Tool Management and Standardization

Strategic tool selection and management protocols significantly impact production efficiency and cost control. Standardized cutting tool libraries reduce inventory complexity while ensuring optimal performance across different part applications.

Tool life monitoring systems track cutting performance in real-time, enabling predictive replacement schedules that prevent unexpected failures. These systems typically improve tool utilization by 30-40% while eliminating scrapped parts from tool breakage incidents.

Carbide cutting tools with advanced coatings extend operational life in demanding applications like hardened steel machining and high-temperature alloys. Modern coating technologies provide 3-5 times longer tool life compared to uncoated alternatives, reducing tool change frequency and associated downtime.

Standardized tool holders and interfaces enable rapid tool changes while maintaining rigidity and precision. HSK and BIG-PLUS systems provide superior gripping force and concentricity compared to traditional CAT holders, improving surface finish quality and dimensional accuracy.

Automated tool changing sequences optimize magazine layouts for minimum cycle time impact. Strategic tool positioning reduces tool-to-tool change times while enabling efficient cutting tool utilization across multiple operations. This planning becomes critical in lights-out manufacturing environments.

Cutting parameter databases maintain optimized speeds, feeds, and depth settings for standardized tool and material combinations. These libraries ensure consistent performance across different operators and shifts while providing baseline data for continuous improvement initiatives.

Quality Control Integration and Real-time Monitoring

In-process measurement systems enable immediate correction of dimensional deviations before parts exceed tolerance limits. Advanced probe technology provides sub-micron measurement accuracy while maintaining production flow efficiency.

Statistical process control integration monitors critical dimensions across production batches, identifying trending issues before they impact quality deliverables. These systems generate automatic alerts when processes approach control limits, enabling proactive adjustments.

Machine condition monitoring tracks spindle vibration, temperature variations, and power consumption patterns that indicate developing problems. Predictive maintenance schedules based on actual machine condition prevent unexpected failures while optimizing maintenance costs.

Surface finish monitoring ensures consistent texture and roughness parameters across production volumes. Portable measurement devices enable rapid verification without disrupting production flow, maintaining quality standards for critical sealing surfaces and bearing interfaces.

Traceability systems capture machining parameters, tool usage data, and quality measurements for each manufactured part. This documentation supports aerospace and automotive quality requirements while enabling rapid root cause analysis when issues occur.

Global Market Characteristics and Manufacturing Considerations

International manufacturing standards vary significantly across different regions, requiring adaptable optimization strategies that accommodate local regulations and customer expectations. European markets emphasize environmental compliance and energy efficiency, while North American customers prioritize cost-effectiveness and delivery speed.

Asian manufacturing environments often feature high-volume production requirements with aggressive cost targets. Optimization strategies must balance efficiency improvements with capital investment constraints. The focus remains on maximizing existing equipment capabilities rather than extensive automation upgrades.

Automotive industry requirements drive much of the global optimization demand, with IATF 16949 quality standards mandating specific process controls and documentation. These regulations influence fixture design, measurement procedures, and traceability requirements across all geographic markets.

Cultural preferences impact communication and implementation approaches. Western customers typically prefer detailed technical documentation and extensive training programs, while Asian markets often emphasize hands-on demonstration and rapid implementation cycles.

Implementation Recommendations and Strategic Considerations

Successful optimization implementation requires phased approaches that minimize production disruption while building organizational capabilities. Start with pilot programs on non-critical components to validate strategies before expanding to high-volume applications.

Training investments prove critical for sustaining optimization benefits long-term. Operators and programmers need comprehensive understanding of advanced techniques to maintain performance levels and continue improvement initiatives. Budget 15-20% of implementation costs for training and development activities.

Measurement and monitoring systems provide objective validation of improvement results while identifying additional optimization opportunities. Establish baseline metrics before implementation to demonstrate return on investment and guide future enhancement priorities.

Supplier partnerships become increasingly important as optimization complexity increases. Cutting tool manufacturers, fixture specialists, and automation integrators contribute expertise that accelerates implementation while reducing risk.

Industry Trends and Future Outlook

Artificial intelligence integration transforms CNC programming through machine learning algorithms that optimize cutting parameters based on real production data. These systems continuously improve performance without human intervention, representing the next evolution in manufacturing automation.

Sustainable manufacturing practices increasingly influence optimization decisions, with energy efficiency and waste reduction becoming primary considerations alongside traditional productivity metrics.

Conclusion

CNC machining optimization for mass production requires systematic approaches that address programming efficiency, workholding standardization, cutting tool management, and quality control integration. Success depends on understanding specific application requirements while implementing proven strategies that deliver measurable performance improvements.

The manufacturing landscape continues evolving toward increased automation and intelligence, making optimization capabilities essential for maintaining competitive positions. Companies investing in comprehensive optimization strategies today position themselves for sustained success in increasingly demanding global markets.

Strategic partnerships with experienced suppliers provide access to advanced capabilities and proven methodologies that accelerate implementation while reducing risk. The combination of internal expertise development and external specialist support creates robust foundations for long-term manufacturing excellence.

Partner with Fudebao Technology for Advanced CNC Machining Solutions

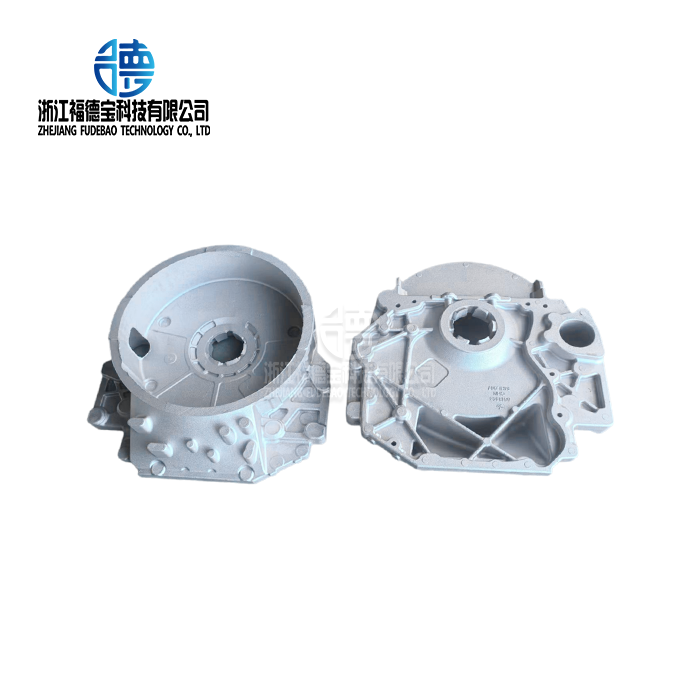

Zhejiang Fudebao Technology delivers comprehensive CNC machining optimization services backed by state-of-the-art equipment and extensive mass production experience. Our facility houses high-speed machining centers, advanced CNC lathes, and integrated casting capabilities that support complete component manufacturing from raw material to finished product.

Our engineering team specializes in developing custom optimization strategies for automotive OEMs, industrial equipment manufacturers, and aerospace applications. We maintain ±0.05mm precision standards while achieving the efficiency levels demanded by high-volume production environments. From prototype development through full-scale manufacturing, our integrated approach ensures seamless transitions and consistent quality delivery.

As a trusted CNC machining supplier to international brands including American HAAS automation and ESS energy storage systems, we understand the critical performance requirements that drive successful partnerships. Our comprehensive capabilities span aluminum alloy, copper alloy, and stainless steel processing with complete surface treatment services.

Ready to optimize your mass production capabilities? Contact us at hank.shen@fdbcasting.com to discuss your specific requirements and discover how our proven optimization strategies can enhance your manufacturing performance.

FAQs

1. What cycle time improvements can be expected from CNC machining optimization?

Properly implemented optimization strategies typically achieve 25-40% cycle time reductions through improved toolpaths, automated workholding, and optimized cutting parameters. Actual results depend on current process efficiency and part complexity, with more significant improvements possible in traditional manufacturing environments.

2. How does fixture standardization impact overall production efficiency?

Standardized fixture systems reduce setup times by 60-70% while improving positional repeatability and part quality consistency. The approach enables rapid changeovers between part families and supports lights-out manufacturing operations through automated loading capabilities.

3. What quality control measures are essential for mass production CNC operations?

Effective quality control combines in-process measurement, statistical process monitoring, and comprehensive final inspection protocols. Real-time feedback systems enable immediate corrections while automated documentation supports traceability requirements and continuous improvement initiatives.

References

1. Manufacturing Engineering Society. "Advanced CNC Programming Techniques for High-Volume Production." Journal of Manufacturing Technology, Vol. 45, Issue 3, 2023, pp. 78-92.

2. American Society of Mechanical Engineers. "Fixture Design Optimization for Automated Manufacturing Systems." ASME Manufacturing Science and Engineering Conference Proceedings, 2023, pp. 156-168.

3. International Journal of Advanced Manufacturing Technology. "Cutting Tool Life Enhancement Strategies in Mass Production Environments." Springer Publishing, Vol. 125, 2023, pp. 2234-2247.

4. Society of Manufacturing Engineers. "Quality Control Integration in Modern CNC Operations." Manufacturing Engineering Magazine, March 2023, pp. 34-41.

5. Automotive Industry Action Group. "PPAP Requirements for CNC Machined Components: Best Practices Guide." AIAG Publications, 4th Edition, 2023.

6. McKinsey Global Institute. "The Future of Manufacturing: Trends in CNC Automation and Optimization." McKinsey & Company Industry Research, 2023, pp. 112-125.

_1756348300182.webp)

_1756349696500.webp)

_1756361423150.webp)