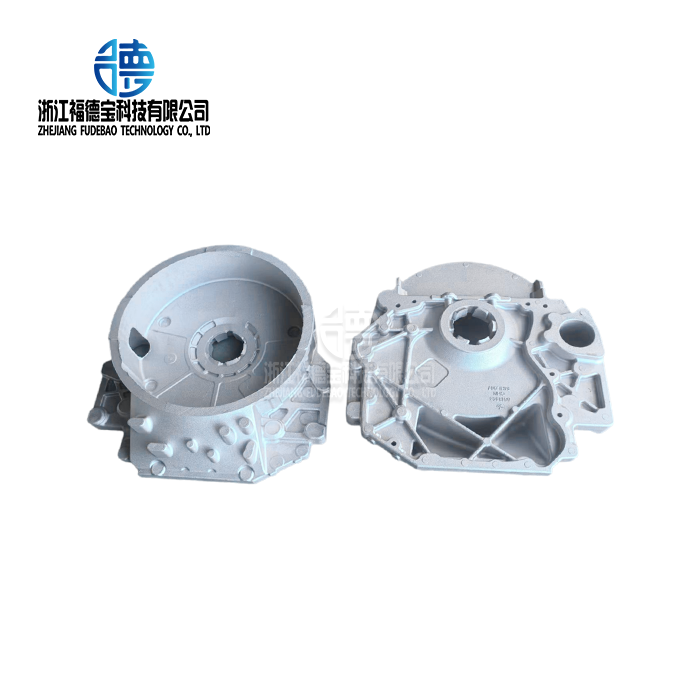

Turbine compressor housing

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Turbine Compressor Housing: High-Performance Solutions by Zhejiang Fudebao

Zhejiang Fudebao Technology Co., Ltd. is your trusted turbine compressor housing manufacturer and supplier. With 24 a long time of exactness casting ability, we convey top-quality lodgings that meet the requesting needs of car, aviation, and mechanical applications. Our products offer prevalent warm resistance, solidness, and exactness, guaranteeing ideal execution in high-stress situations.

Product Description

Our turbine compressor housings are engineered for excellence, combining advanced materials with precision manufacturing. These lodgings ensure imperative components whereas optimizing wind current and weight control. Created from high-grade amalgams, they withstand extraordinary temperatures and weights, guaranteeing long-lasting unwavering quality in turbocharged motors and mechanical compressors.

Parameters

| Specification | Details |

|---|---|

| Material | Heat-resistant alloys (e.g., Inconel, Hastelloy) |

| Temperature Resistance | Up to 1000°C (1832°F) |

| Pressure Rating | Up to 50 bar (725 psi) |

| Dimensional Tolerance | ±0.05mm |

| Surface Finish | Ra ≤ 0.8μm |

| Weight | Customizable (typically 2-20 kg) |

| Corrosion Resistance | Excellent |

Applications

- Automotive turbochargers

- Aircraft engines

- Industrial gas turbines

- Power generation systems

- Oil and gas compressors

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been a leader in precision metal casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang, houses advanced equipment for comprehensive manufacturing processes. We serve worldwide clients over car, mechanical, and vitality divisions, giving customized metal arrangements with unmatched quality and advancement. Our commitment to fabulousness is supported by different licenses and a strong quality administration framework.

Why Choose Us?

- 24 years of specialized experience in precision casting

- Advanced manufacturing capabilities with ±0.05mm accuracy

- Customization options to meet specific industry requirements

- Rigorous quality control and material testing

- Competitive pricing for both large-scale and small batch orders

- Rapid prototyping and flexible production scheduling

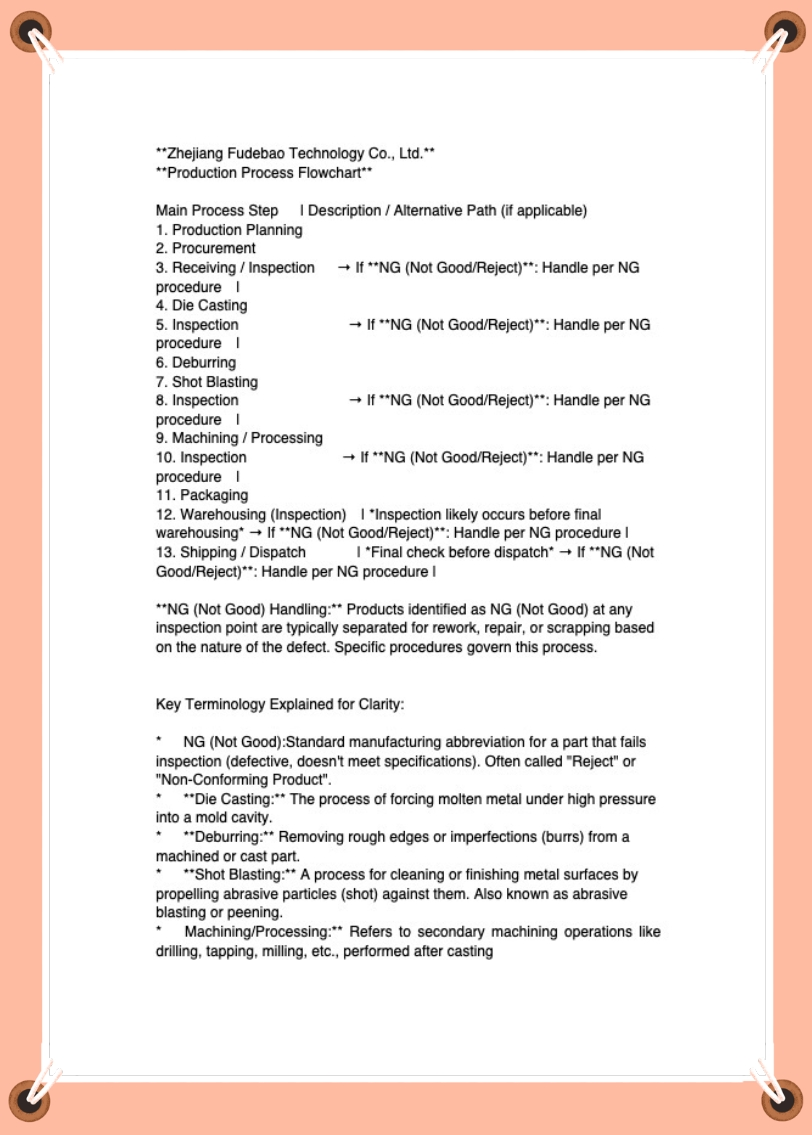

Production Process

- Material Selection and Preparation

- Mold Design and Manufacturing

- Casting (Low-Pressure or Investment Casting)

- Heat Treatment

- CNC Machining for Precision Finishing

- Quality Inspection and Testing

- Surface Treatment (if required)

- Final Assembly and Packaging

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- AS9100 Aerospace Standard Certification

- ISO 14001 Environmental Management System

Packaging and Shipping

- Custom protective packaging to prevent damage

- Vacuum-sealed options for corrosion protection

- Wooden crates for bulk shipments

- Global logistics partnerships for efficient delivery

- Express shipping available for urgent orders

FAQ

Q1: What is the minimum order quantity for the products?

A1: We offer flexible MOQs starting from 5 pieces for prototype orders and can scale up to thousands for mass production.

Q2: Can you provide custom designs for the products?

A2: Absolutely! We offer full customization services based on your technical drawings or specifications.

Q3: What is the typical lead time for a product order?

A3: Lead times vary based on complexity and quantity, but typically range from 2-4 weeks for standard orders and 4-6 weeks for custom designs.

Q4: Do you offer material certifications with your products?

A4: Yes, we provide full material traceability and certifications upon request to ensure compliance with your industry standards.

Contact Us

Ready to elevate your turbine performance with our high-quality compressor housings? Contact our expert team today for a personalized consultation and quote.

Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology be your partner in precision and innovation for turbine compressor housing solutions.

_1756348623524.webp)

_1756348780785.webp)

_1756349002499.webp)

_1756349146076.webp)

_1756349696500.webp)

_1756349862928.webp)

_1756350046757.webp)