Aluminum die casting is one of the most important new ways to make things in the car and electric vehicle businesses right now. This improved process meets the complicated needs of current car design while providing high accuracy, lowering weight, and low cost. From standard internal combustion engines to cutting-edge electric powertrains, makers can use aluminum die casting to make complex parts that are both long-lasting and work well. The technology helps the industry move toward making cars that are lighter, more fuel-efficient, and meet strict environmental standards and customer demands.

Understanding Aluminum die casting in Automotive and EV Manufacturing

During the aluminum die casting process, melted aluminum metal is poured into specially designed steel molds while being under very high pressure, usually between 1,500 and 25,000 PSI. This way of making things makes complicated shapes with very accurate measurements and great surface finishes that often get rid of the need for extra cutting.

Technical Process and Material Advantages

Modern aluminum alloys used in cars have amazing strength-to-weight ratios. Some types can reach tensile strengths of over 300 MPa while still having densities only about a third of those of steel. Special metals like A380, A383, and ADC12 are used in the process. Each one was designed for a different car purpose that needs a different set of mechanical and heat qualities.

Manufacturing Efficiency and Quality Control

Die casting processes can be finished in seconds instead of minutes, which lets a lot of them be made at once to meet the needs of the car business. Modern process tracking systems keep an eye on factors like temperature, pressure, and speed in real time. This makes sure that the quality stays the same over thousands of production runs. Because of this level of control, die casting is very appealing to automakers who need both accuracy and the ability to make large quantities of parts.

Top Ways Aluminum die casting Is Used in Car and EV Parts

The car industry uses aluminum die casting for a variety of important purposes, each of which benefits from the distinctive characteristics of this manufacturing process. When procurement professionals understand these uses, they can find ways to make their car projects lighter, cheaper, and better at performing their tasks.

Engine and Powertrain Components

For the best speed and fuel economy, traditional car powertrains depend a lot on aluminum die cast parts. Some of the most difficult jobs are engine blocks, cylinder heads, and transmission housings, which need to keep heat under control and stay structurally sound. Extreme temperatures must not affect these parts, and they must stay within very tight limits in order to bond properly and work mechanically.

Aluminum's ability to fight rust, as utilized in aluminum die casting, is shown off in oil pans and valve covers. This is especially useful in tough working conditions where chemicals and temperature changes are constant. The material's high thermal conductivity helps get rid of heat efficiently, which makes engines work better and last longer.

Electric Vehicle Battery and Motor Systems

Particularly in battery management systems and electric motor housings, electric cars offer special possibilities for aluminum die casting uses. Aluminum is light and good at blocking electromagnetic waves, which are both useful qualities for battery cases. Motor housings use aluminum's temperature conductivity to control the heat that is made during operation.

EV cooling system parts use aluminum's better heat transfer qualities to keep sensitive electrical parts at the best working temperatures. Die casting is being used more and more to make heat sinks, thermal management plates, and cooling pipes with complex internal shapes that make heat exchange as efficient as possible.

Structural and Chassis Applications

More and more, aluminum die-cast parts are being used in automotive safety systems to reduce weight without sacrificing structural strength. Die casting helps meet both efficiency and safety goals, as shown by suspension bearing frames, steering system housings, and brake component cases.

As a result, these structure uses often need complicated shapes that are hard or expensive to make with standard manufacturing methods. Die casting lets multiple functions be built into a single part, which makes the whole car more reliable by lowering the number of parts that need to be put together and the number of places where they could fail.

Design Guidelines and Quality Considerations in Aluminum die casting for Automotive and EV

For aluminum die casting to work well in automotive uses, designers must pay close attention to design rules that make the parts easier to make and better at what they do. These rules make sure that parts meet strict quality standards for the car industry while getting the most out of the casting process.

Critical Design Parameters

Wall width consistency in aluminum die casting is a key factor in avoiding flaws and making sure that the material qualities are the same all the way through the component. For automotive uses, wall widths should be between 2.5 mm and 6 mm, with slow changes to avoid stress buildup that could cause the material to fail early.

Draft angles, which are usually between 1 and 3 degrees, make it easier to take the part out of the mold while also reducing surface flaws. The right fillet sizes at areas that touch each other lower stress concentrations and improve wear resistance. These are very important in automobile uses where parts are loaded and unloaded many times over the course of their life.

Quality Assurance and Testing Protocols

When it comes to quality control, automotive die casting often goes above and beyond what is needed in other businesses. Non-destructive testing methods, like X-ray checking and acoustic testing, help find flaws inside a component that might affect its safety or performance.

Coordinate measuring tools are used for dimensional checking to make sure that parts fit and work properly in car setups within very tight limits. Surface finish standards often list hardness levels that allow for proper closing or a nice look, based on the part's use.

Procurement Strategies for Aluminum die casting in Automotive and EV Projects

For effective purchase of aluminum die cast components, you need to know what makes this manufacturing process special and what possible providers can do. Cost isn't the only thing that strategic buying choices affect; they also affect quality, service performance, and the security of the supply chain in the long run.

Supplier Evaluation Criteria

Automotive licensing requirements, especially IATF 16949 and ISO 9001, are the minimum standards that die casting providers to the auto business must meet. These licenses show that you are committed to quality control systems that are built for use in the car business and that you know what those systems need to do.

When evaluating production capacity for aluminum die casting, it's important to look at both what's currently possible and what could be possible in the future as car plans change. Suppliers who have more than one die casting machine and various sets of tools can make the supply chain safer and handle the volume changes that are usual in making cars.

Cost Structure and Value Engineering

Die casting costs a lot of money up front for the tools that are used, but these costs are spread out over many production runs. When procurement workers understand this cost structure, they can look at the overall cost of the program instead of just looking at the prices of each item. Most of the time, promises to buy in bulk lead to better price systems and give sellers the stability they need to justify investing in tools.

Value engineering chances often appear during shared design reviews that use the die casting optimization knowledge of the provider. Through these relationships, it's possible to find changes to designs that make production easier, raise quality, or lower costs while still meeting performance standards.

Conclusion

Aluminum die casting continues to lead the way in new ideas for making cars and electric cars. It makes it possible to make lightweight, high-performance parts that meet the stricter standards of the industry. Because the technology can make very complicated shapes with great accuracy, it is essential for current car designs that aim for a balance between speed, efficiency, and cost-effectiveness. As the auto industry moves toward electric cars and new materials, die casting will become an even more important part of making these technology improvements possible while still meeting the high standards of safety and dependability that customers expect.

FAQs

What factors decide if aluminum die casting is a good choice for a certain car part?

How well it works depends on how complicated the part is, how many of them need to be made, what mechanical and heat qualities they need, and how much they cost generally. When accuracy in measurements and surface finish are very important, die casting is the best way to make high-precision, long-lasting parts in medium to large quantities. This way of making things works especially well for parts that need complex internal shapes or thin wall sections.

How can we be sure that the metal die-cast parts we make meet OEM standards and don't have any flaws?

Using strict mold design methods, strong process controls, thorough quality checks, and working with qualified makers can help reduce flaws and make sure that standards set by the car industry are met. For uniform quality, you need to have plans for statistical process control, preventative maintenance, and regular process tracking.

What are the usual wait times and number limits that providers of aluminum die casting offer?

Lead times for making new tools are usually between 8 and 16 weeks. Once the tools have been tested and found to be functional, production processes can begin. Different providers have very different production abilities. Depending on the complexity and size of the parts, many sites can make thousands of parts every day.

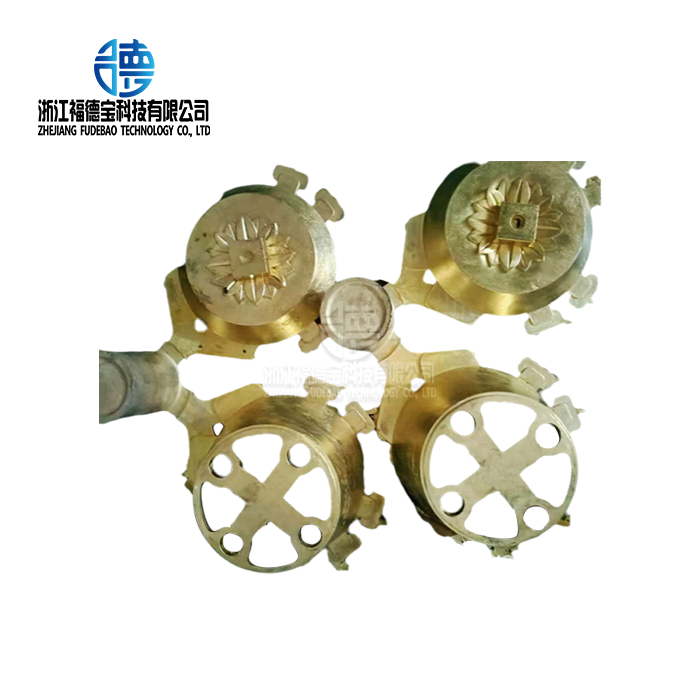

Partner with Fudebao Technology for Advanced Aluminum die casting Solutions

Zhejiang Fudebao Technology is a leading aluminum die casting company that makes parts for cars and electric vehicles. They offer precision-engineered solutions that meet the strictest industry standards. Our full range of manufacturing services covers the whole production cycle, from the initial idea to delivering the finished part, making sure that they work seamlessly with your supply chain.

Our cutting-edge factory has advanced die casting machines, high-speed CNC machining centers, and accurate measuring tools that let us regularly meet standards of ±0.05mm. We are a perfect aluminum die casting source for important car uses where size accuracy has a direct effect on safety and performance.

The ability to use both standard die casting methods and low-pressure casting methods together gives manufacturers more options for how to make parts that meet specific needs. The engineers on our team work closely with automakers and tier-1 suppliers to come up with unique solutions that improve car performance while lowering the overall cost of production.

We welcome buying directors, procurement professionals, and managers of car engineering to look into business possibilities that take advantage of our skills in processing aluminum alloys and making precise machines. Get in touch with us at hank.shen@fdbcasting.com to talk about your unique part needs and find out how our aluminum die casting services can help your next car or electric vehicle project.

References

Automotive Industry Action Group. "Advanced Product Quality Planning and Control Plan Reference Manual." AIAG Publications, 2019.

Society of Automotive Engineers. "Aluminum Die Casting Alloys for Automotive Applications." SAE International Technical Paper Series, 2021.

International Journal of Metalcasting. "Advances in Aluminum Die Casting for Electric Vehicle Applications." Springer Publications, 2022.

North American Die Casting Association. "Die Casting Process Guidelines for Automotive Components." NADCA Technical Publications, 2020.

Materials Science and Engineering Institute. "Thermal Management Solutions in Electric Vehicle Battery Systems." Academic Press, 2023.

Automotive Manufacturing Research Center. "Lightweight Materials in Modern Vehicle Design." Industrial Press, 2021.

_1756346668222.webp)

_1756348489473.webp)

_1756349696500.webp)

_1756350046757.webp)