Many exporters go to China for CNC machining services because the country has low prices, improved production skills, and a wide range of materials available. Chinese makers offer precision machining services that meet international quality standards and are much cheaper than those offered by other countries because they use less labor and run their factories more efficiently. Because the country has invested in modern equipment and a trained workforce, it can deliver complicated parts with tight standards. This makes it a popular place for companies around the world to get precision-machined parts for the automobile, aircraft, and industrial sectors.

Why China Leads the Global CNC Machining Outsourcing Market?

Computer Numerical Control (CNC) cutting has changed the way things are made today, making businesses all over the world need precision-engineered parts in ways that have never been seen before. This computerized manufacturing method makes it possible to make complicated parts with great accuracy and consistency, which is helping outsourcing markets grow around the world.

More and more, importers are looking for CNC machining services to get access to specialized knowledge, lower production costs, and new manufacturing technologies without having to spend a lot of money on equipment. Companies look for foreign supply lines that offer better value because they want to stay ahead of the competition.

This detailed guide looks at why China has become a top choice for outsourcing precision machining. It talks about market trends, competitive benefits, how to choose a seller, and how to work effectively with Chinese makers.

Understanding CNC Machining and Its Market Importance

Fundamentals of Computer-Controlled Manufacturing

Precision cutting, grinding, and turning are done on different materials by computer-controlled tools in the complex production process known as CNC machining. The first step is to write specific directions that tell machine tools how to work with complicated shapes. This makes sure that high-quality parts are always made.

Some of the most important steps are turning a CAD drawing into machine code, setting up the part, choosing the right tools, and automating multi-axis operations. This methodical approach gets rid of the differences that people make while still producing very accurate parts with perfect sizes and finishes.

Industrial Applications and Material Versatility

Precision cutting, specifically through CNC machining, is used a lot in big businesses to make important parts. Automakers need engine parts, frames, and housings made of metal that are very accurate in terms of size. Specialized metals are used to make parts for aerospace uses that are both light and strong. Biocompatible materials must be made to exact specs for companies that make medical devices.

Aluminum alloys, stainless steel, titanium, copper alloys, and customized plastics are just some of the materials that can be used in this process. Machining each material is different, but trained workers can solve these problems by choosing the right cutting speeds, tools, and cooling methods.

Quality Standards and Tolerance Requirements

Tolerances in modern production are getting tighter and tighter, often within ±0.05mm for important uses. Modern measure tools and quality control systems make sure that all parts meet strict requirements during production runs. Because it can be so precise, CNC machining is a must for fields where part quality has a direct effect on safety and performance.

Why China Has Become a Preferred Hub for CNC Machining Outsourcing?

Cost Advantages and Economic Factors

China's industrial environment offers big cost savings by lowering the cost of labor, finding materials quickly, and taking advantage of economies of scale. Because of these things, Chinese makers can give reasonable prices while keeping quality levels on par with Western companies.

Aside from saving money on labor, Chinese sellers also benefit from linked supply lines that lower the cost of materials and make transportation easier. This all-inclusive cost structure makes strong value offers for buyers who want to get the most for their money without sacrificing quality.

Advanced Manufacturing Infrastructure

China has made huge investments in modern industrial technology, which has made it the world leader in precise cutting. Modern CNC centers, multi-axis tools, and computerized production lines are on par with those in developed markets.

To improve quality and efficiency, particularly in CNC machining, Chinese makers are always updating their tools and using Industry 4.0 technologies. This dedication to technological progress makes sure that foreign customers can access cutting-edge production tools.

Production Flexibility and Scalability

Chinese providers are great at meeting a wide range of production needs, from making quick prototypes to mass production. Because of this, clients can change the amount they produce based on what the market needs without having to switch providers or miss supply dates.

Quick-turn skills help shorten the time it takes to build a new product, and well-established production systems can handle big orders quickly and easily. Because they can do so many things, Chinese makers are a good choice for businesses with a wide range of production needs.

Comparison: China CNC Machining vs. Other Manufacturing Solutions

Precision Advantages Over Alternative Methods

CNC methods are better at making useful parts that are strong and accurate than 3D printing, injection molding, and regular milling. Additive manufacturing is great for making prototypes, but made parts are better for production because they have better material qualities and are more accurate in size.

- The following comparison shows some of the best things about precision machining:

- Because the grains are still whole, the material is stronger than 3D-printed parts.

- The quality of the surface finish is better than injection casting for metal parts.

- Dimensional limits reach levels that can't be reached by hand-machining.

- It's possible to make complex shapes without having to buy expensive casting tools.

Because of these benefits, CNC machining is the best way to make load-bearing parts, precise structures, and other things that need better material qualities.

Economic Considerations for Different Production Volumes

Cost-effectiveness changes a lot depending on how much is being made and how complicated it is. CNC machining has low setup costs compared to injection casting, which needs expensive tools for low-volume runs. Economies of scale help lower the cost of each part by a large amount when a lot of them are made.

Lead time is another factor that affects the choice of method. When it comes to samples and small amounts, machining is faster, while once the casting is finished, molding is better for big production runs.

How to Choose a Reliable CNC Machining Supplier in China?

Certification and Quality Standards Evaluation

To find reliable manufacturing partners, you need to carefully look at their certifications and quality control systems. Check for ISO 9001 approval and standards specific to the business, such as TS 16949 for car use and AS 9100 for aircraft parts.

Quality records should have thorough inspection reports, certificates for materials, and records of how they were made. These qualifications show that you are dedicated to organized quality management and following the rules.

Technical Capability Assessment

Check the professional skills of the provider by looking at their equipment specs, knowledge of materials, and ability to meet tolerances. For your unique purpose, ask for model parts that show the level of accuracy and surface finish you need.

How well people can talk to each other is very important to the success of a project. Pick providers with engineering support staff that knows the technical details and can give feedback on designs while they are being developed.

Logistics and Compliance Considerations

To successfully source goods like CNC machining components from other countries, you need to know how to ship goods, follow customs rules, and meet trade compliance requirements. Work with sellers who know how to export and can give you the right paperwork for a smooth customs process.

To keep problems as low as possible during the import process, be clear about what you expect in terms of packing, shipping times, and quality checking procedures.

Fudebao Technology: Your Trusted Partner for Precision Manufacturing

Comprehensive Manufacturing Capabilities

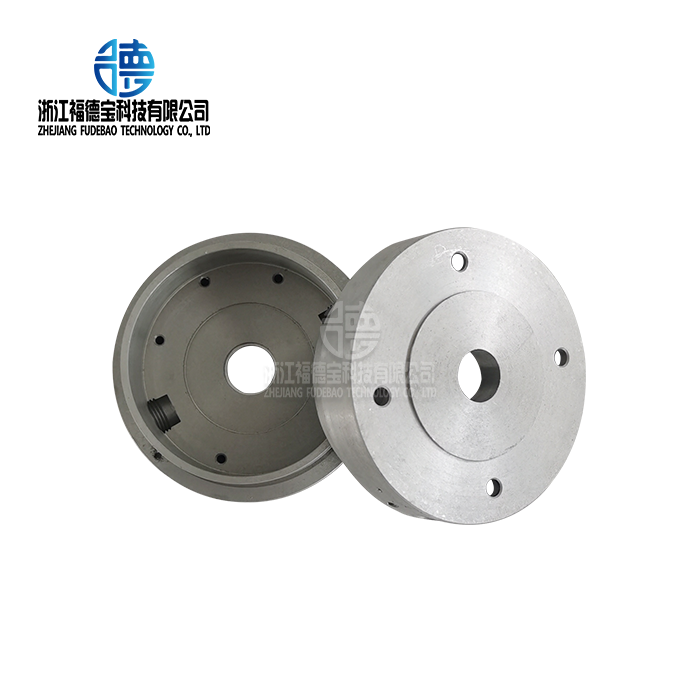

Fudebao Technology specializes in precision cutting and casting in aluminum alloy, copper alloy, and stainless steel. Our combined method includes the whole production process, from heating and casting to finishing and surface treatment. This means that we can deliver the whole product, from the blank to the finished one, all in one place.

We have high-tech tools like high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment at our site. This complete setup meets a wide range of manufacturing needs in aircraft, industrial equipment, tool making, and the automobile industry.

Precision and Quality Assurance

We can machine parts with an accuracy of up to ±0.05mm, which meets the strict needs of medical equipment housings, aircraft parts, and precision parts for cars. Our quality control system makes sure that performance stays the same throughout production runs and that important applications can be fully tracked.

Our experience covers a wide range of industry needs and quality standards, from working with middlemen to having direct supply relationships with foreign names like American HAAS automation and ESS energy storage systems.

Conclusion

China has become one of the best places to get precision cutting done, particularly for CNC machining, because of its low costs, advanced technology, and production know-how. When you combine reasonable prices, state-of-the-art tools, and production freedom, you get a great deal for global exporters looking for trusted manufacturing partners.

To outsource CNC machining successfully, you need to carefully choose your suppliers, have clear rules for how to communicate, and fully understand the quality standards. Companies that take the time to build strong relationships with qualified Chinese makers can often save a lot of money while still getting the quality standards they need for their uses.

Frequently Asked Questions

What kinds of materials can Chinese CNC machining companies work well with?

Most of the time, Chinese producers work with aluminum alloys, carbon steel, titanium, copper alloys, stainless steel, and different types of industrial plastics. A lot of facilities focus on aerospace-grade materials and medical-grade metals, so they can give a wide range of materials for a variety of uses.

How do the specifications for milling that come from Chinese sources compare to those in the West?

For precise uses, leading Chinese makers often get limits within ±0.05mm, which is the same as Western facilities. Quality is more affected by the choice of provider and the powers of the tools than by where it is located.

In general, how long does it take for CNC machining jobs to be sent from China?

Lead times depend on how complicated the job is and how much of it there is. Usually, prototype parts take one to two weeks, and production runs can take three to six weeks, based on the number of parts and the requirements. Often, faster plans can work for orders that need to be filled quickly.

Partner with Fudebao Technology for Superior CNC Machining Solutions

Partner with a reliable CNC machining provider that offers consistent quality and low prices to streamline your global buying strategy. Fudebao Technology serves automobile, aircraft, and industry clients around the world with cutting-edge tools and decades of experience in making.

Our ability to combine casting and precise machining lets us make complicated parts quickly while still meeting the tight standards your uses need. As a well-known aluminum casting standard company, we know how important it is for your business that the dimensions are correct and the material is intact.

Find out how our all-in-one industrial options can help you improve your supply chain and lower the cost of buying things. Send us an email at hank.shen@fdbcasting.com to talk about your unique needs and get quotes for your next job.

References

Manufacturing Engineering Society. "Global CNC Machining Market Analysis and Industry Trends." Journal of Manufacturing Technology, Vol. 45, 2023.

International Trade Commission. "Competitive Analysis of Global Precision Machining Markets." Industrial Manufacturing Report, 2023.

American Society of Mechanical Engineers. "Quality Standards in International CNC Machining Supply Chains." ASME Manufacturing Quarterly, 2023.

China Machinery Industry Federation. "Technological Advancement in Chinese Manufacturing Sectors." Industrial Development Review, 2023.

Global Manufacturing Research Institute. "Cost-Benefit Analysis of International Manufacturing Outsourcing." Manufacturing Economics Journal, 2023.

Precision Manufacturing Association. "Best Practices for International Supplier Selection and Management." Supply Chain Management Review, 2023.

_1756360265131.webp)

_1756361423150.webp)