Making important parts for big machinery and mining equipment through sand casting is one of the most flexible and cost-effective ways to make things. This tried-and-true method lets makers make big, complicated parts that can work in harsh conditions and still keep their shape and material integrity. Knowing the different uses of sand casting helps sourcing workers and engineers choose the best manufacturing partners and make the most of their production strategies. This detailed guide looks at the important roles that sand casting plays in many heavy industry settings. It covers everything from engine housings to the structural parts that keep mines running smoothly.

Overview of Sand casting in Heavy Machinery and Mining Equipment

Over the past few decades, the sand casting process has changed a lot, becoming an essential way to make strong parts that power big machinery and mining activities around the world. This method used in foundries includes making models out of carefully mixed sand that can handle the large sizes and complicated shapes needed in industrial settings.

Fundamental Process Steps for Heavy-Duty Applications

Pattern making is the first step in sand casting. This is where experts make exact copies of the part that is needed. The design is pressed into sand to make prints of the cavities. Next, the mold is put together, and metal is poured at controlled temperatures. Cooling times depend on the thickness of the part and the type of metal used. For example, heavy machinery parts often need longer solidification times to get the best grain structure and mechanical qualities.

Material Compatibility and Alloy Selection

Materials used in heavy machines need to be able to handle a lot of stress, wear, and weather problems. Cast iron is still the best material for many parts of mine tools because it doesn't wear down easily and doesn't cause vibrations. For structural uses, steel alloys have better strength-to-weight ratios, and for tough mining settings, specific metals have better rust protection.

Sand Mold Types and Their Advantages

Green sand molds use clay-bonded sand mixes that are easy to shape and don't cost much for big production runs. Resin-bonded sand systems are great for precision parts that don't need a lot of post-processing because they provide better measurement accuracy and surface finish quality. Depending on the production rate, required measurement tolerances, and surface quality standards, each type of mold has its own set of benefits.

Top 5 Applications of Sand casting in Heavy Machinery and Mining Equipment

Sand casting is very useful for making important parts for a wide range of heavy machinery uses because of its adaptability. It's clear from these examples that casting methods can meet the high performance needs of industrial equipment that works in tough conditions.

Engine Components and Housings

Some of the most difficult parts to make in big machinery are engine blocks, cylinder heads, and transmission housings. These parts have to keep their exact internal shapes while being subjected to huge changes in temperature and mechanical stress. Manufacturers can use sand casting to make complicated internal paths for oil and water flow while keeping the structure's integrity for reliable operation. The process makes it possible for single components to have walls of different sizes, which improves weight distribution and heat management.

Mining Crushers and Wear-Resistant Parts

A lot of the time, jaw crushers, cone crushers, and impact breakers use sand-cast parts that can handle being worn down by treated materials all the time. Casting high-chromium iron alloys makes it possible to make frames for crushers, wear plates, and impact bars that are very hard and don't wear down easily. Engineers can use wear-resistant plugs and the best part shape for maximum material flow and breaking efficiency because sand casting is so flexible.

Hydraulic System Elements

It would be hard or impossible to make complex internal passageways into solid stock for hydraulic pumps, valve bodies, and pipelines. Sand casting lets you make complicated fluid paths with smooth changes that keep pressure losses and turbulence to a minimum. Many of these parts have multiple fastening and connection spots that can be cast to a nearly net shape. This cuts down on the need for cutting and production costs while still meeting hydraulic performance standards.

Structural Frames and Support Components

Sand casting's ability to create big, complex forms in a single piece is useful for equipment frames, support brackets, and mounting parts. This method gets rid of the need for multiple bonded parts, which lowers stress collection spots and makes the structure stronger overall. The process works with different wall widths and built-in support plates that make the best use of strength-to-weight ratios while keeping the manufacturing process as efficient as possible.

Conveyor and Material Handling Parts

For effective material transfer, conveyor drums, roller housings, and tube parts need to be long-lasting and consistent in size. These parts are made by sand casting, which gives them a great surface finish that makes belt wear and upkeep less of a problem. Being able to cast integrated bearing plates and greasing lines makes assembly easier and makes sure that everything is aligned correctly and works reliably.

Comparative Advantages: Sand casting vs Other Casting Methods in Heavy Equipment Manufacturing

To choose the best casting method, you need to carefully think about the part needs, the production volume, and the cost. When architects know how sand casting stacks up against other methods, they can make choices that combine cost, quality, and performance.

Sand casting vs Die Casting for Large Components

Although die casting gives better surface finish and accuracy in measurements, sand casting is better for making big, heavy machinery parts. In contrast to sand casting, which can handle almost any component size, die casting has tooling costs that are expensive for parts that are too big. Sand casting also allows for more material freedom, allowing for the use of iron and steel metals that might not work well with die casting.

Investment Casting Comparison

Investment casting has a great surface finish and accurate measurements, but it can't make heavy machinery parts that are too big or too expensive to make. Sand casting is a cheaper way to make big parts that can still be made to acceptable standards with the right process control. The high-strength metals frequently needed in mining and building tools are supported by the benefits of sand casting in material selection.

Green Sand vs Resin Sand Selection Criteria

For high-volume production, green sand methods are cheaper and better for the environment, while resin-bonded sand gives you better control over the dimensions and quality of the surface. Manufacturers of mining equipment usually pick based on the complexity of the part and the tolerance requirements. For example, resin sand is best for precise hydraulic parts, while green sand is better for structural parts where small differences in size are okay.

Addressing Common Challenges and Defects in Sand casting for Heavy Machinery

For sand casting quality control, it's important to know what problems could happen and take steps to stop them. This way, the parts will work reliably in tough situations. Effective flaw management has a big effect on how well the end product works and how efficiently the production process works.

Porosity and Inclusion Control

Gas porosity is usually caused by not enough air flow or too much water in sand mixtures. Inclusion flaws are caused by mold erosion or metal that is contaminated. Newer filter systems and controlled dumping methods make these problems less likely, and better ways to prepare the sand make it less likely that gases will form. Metal chemistry research done on a regular basis makes sure that alloys are clean and that finished parts have the best mechanical qualities.

Dimensional Accuracy Optimization

To get uniform sizes, you need to pay close attention to pattern creation, sand packing, and temperature expansion. Pattern allowances need to take into account how much the metal will shrink as it hardens, and the form of the mold affects how fast heat is extracted and how stable the shapes are. Statistical process control methods help find patterns and fix problems before they affect the quality of the production.

Advanced Inspection Technologies

These days, foundries use X-rays, ultrasound tests, and computerized tomography to find flaws inside parts that might affect how well they work. Before parts are put into service, these non-destructive testing methods find holes, inclusions, and other structural problems. Finding defects early on cuts down on guarantee claims, makes customers happier, and helps with efforts to keep improving.

Procurement Insights: Selecting the Right Sand casting Supplier for Heavy Machinery Parts

To successfully buy sand-cast parts, you need to carefully evaluate the suppliers you're considering and make sure they understand your technical needs. Knowing what a foundry can do and how they handle quality helps buyers build relationships that work and get regular results.

Capability Assessment and Certification Requirements

It is important to make sure that the foundry's tools, size limits, and ability to handle alloys for sand casting are in line with the needs of the project. Quality certifications like ISO 9001 and standards specific to the business show that the company is dedicated to using consistent procedures and records. Supplier checks show what the real production skills and quality control methods for sand casting are, which might not be clear from the first conversations.

Lead Time and Cost Optimization Strategies

Knowing the foundry's schedule and capacity limits helps buyers make good plans for when to buy things. Development of patterns, preparation of tools, and planning of production schedules all have an effect on prices and delivery dates. Long-term relationships often give you more schedule flexibility and lower costs than one-time purchases, especially for parts that need special metals or complicated shapes.

Technical Specification Development

Documenting measurement limits, material needs, and performance standards in a clear way avoids confusion and holds suppliers responsible. From the start of the project, detailed plans, lists of materials, and rules for inspections set the quality standards. Keeping in touch during the production process helps solve problems before they affect delivery times or the quality of the parts.

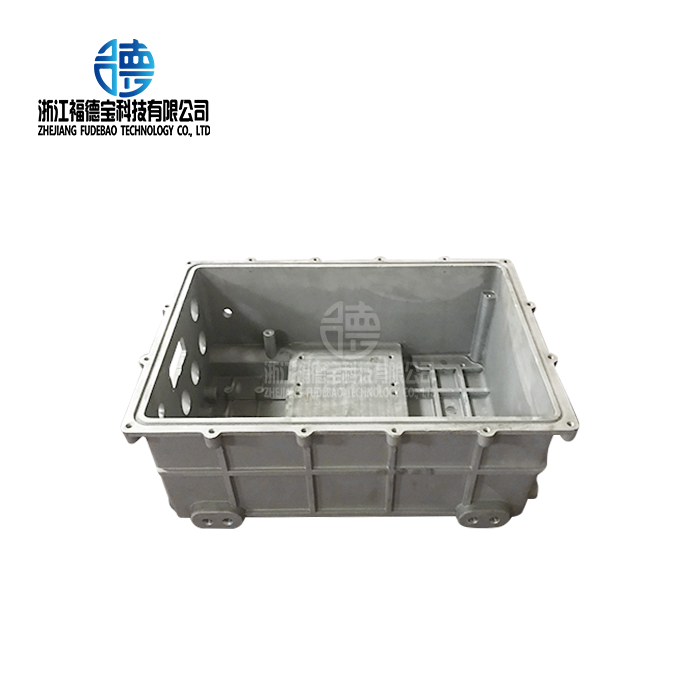

The Zhejiang Fudebao Technology Co., Ltd. is the leader in the sand casting for heavy machinery business. Our full-service foundry has high-tech melting systems, precise casting tools, and combined machine centers that make parts from raw materials to finished specs. We've been working with the car, industrial equipment, and machinery making industries for decades, so we know the unique problems heavy machinery makers face and can make solutions that meet their exact performance needs.

Conclusion

Sand casting is still an important part of making heavy machinery and mining equipment because it gives manufacturers a lot of options for making big, complicated parts that have to work well. Because the process is flexible with materials, can handle different sizes, and is cost-effective, it is the best choice for many commercial uses. Procurement experts can make better choices that meet both performance and cost goals when they know about the different uses, comparative benefits, and quality factors. As technology keeps getting better, sand casting methods will change to meet more complex needs while keeping the basic benefits that have made this process so important to heavy industry makers.

FAQs

What kinds of metals are most often used to make mining tools out of sand casting?

The main materials used for sand casting mining tools are cast iron, malleable iron, and different steel metals. Cast iron is great for parts of crushers and buildings because it doesn't wear down easily, but ductile iron is better at withstanding impacts. Steel alloys are used in situations where high strength-to-weight ratios or certain rust protection qualities are needed.

In general, how long does the sand casting process take for big parts for heavy machinery?

Production times depend a lot on the size, complexity, and ability of the factory. From blueprint to finished casting, simple structure parts may take two to four weeks. More complicated hydraulic housings or big engine blocks can take six to twelve weeks. Often, the parts of making a new part that take the longest to make are pattern development and manufacturing preparation.

Can sand casting make the complicated shapes that current mining equipment needs?

Sand casting is great for making forms with complicated internal patterns, undercuts, and undercuts that would be hard or impossible to make from pure metal. Complex internal passages can be made with advanced core-making methods, and complex exterior passages can be made with multi-part models. The limitations of the process are mostly minimum wall thickness and draft angle rules, not limits on physical complexity.

Partner with Fudebao Technology for Superior Sand casting Solutions

Zhejiang Fudebao Technology can help you with your heavy machinery part needs by offering a wide range of sand casting and precision milling services. Our modern quality control systems and traditional casting skills work together in our state-of-the-art building to make sure that we always deliver parts that meet your exact specs. We are experts at making aluminum alloys, copper alloys, and stainless steels, and we have a lot of experience working with clients around the world who make cars, industrial equipment, and machines. Our unified method includes the whole process, from melting to treating the surface. This allows for one-stop transport and accuracy of up to ±0.05mm. As a reputable sand casting provider, we know how important quality, dependability, and on-time delivery are for big machines. Email us at hank.shen@fdbcasting.com to talk about your unique needs and find out how our experience can help your manufacturing success.

References

1. Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

2. Brown, John R. "Foseco Foundry Practice: A Guide to Sand Casting and Core Making." Butterworth-Heinemann, 2014.

3. American Foundry Society. "Sand Cast Iron Design and Application Manual." AFS Technical Publications, 2018.

4. Stefanescu, Doru M. "Science and Engineering of Casting Solidification." Springer International Publishing, 2017.

5. Brooks, Charlie R. "Principles of the Heat Treatment of Plain Carbon and Low Alloy Steels for Sand Casting Applications." ASM International, 2016.

6. International Association of Mining Equipment Manufacturers. "Heavy Equipment Component Manufacturing Standards and Best Practices." IAEM Technical Report, 2019.

_1756346259673.webp)

_1756349862928.webp)

_1756361323684.webp)

_1756361494985.webp)