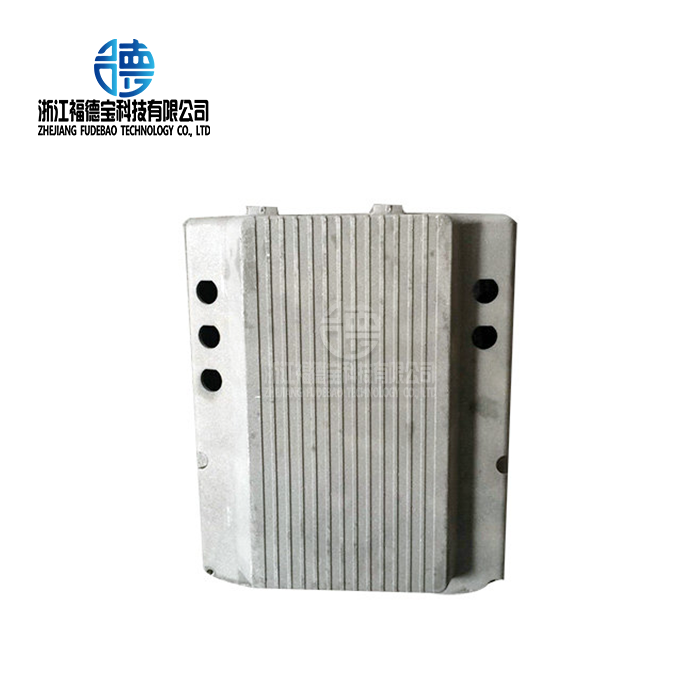

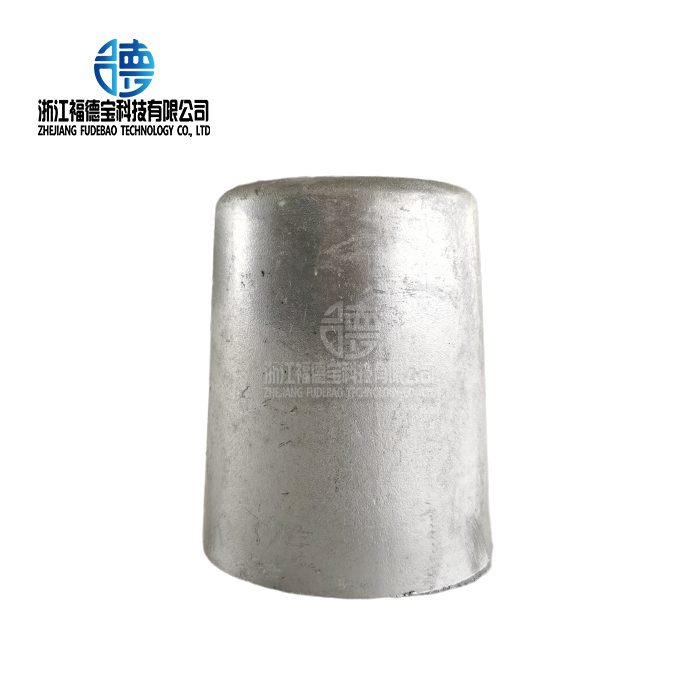

Explosion-proof lamp shell casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:cast aluminum mold

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Explosion-proof Lamp Shell Casting: Durable Protection for Hazardous Environments

Zhejiang Fudebao Technology Co., Ltd. is a leading manufacturer and supplier of high-quality explosion-proof lamp shell castings. With 24 a long time of involvement in accuracy casting, we offer predominant items that meet thorough security benchmarks. Our products are planned to withstand cruel conditions in oil & gas, chemical handling, and mining businesses.

Product Description

Our explosion-proof lamp shell castings are engineered for maximum durability and safety in hazardous environments. Made from corrosion-resistant aluminum amalgam, these castings give great assurance against dangerous climates whereas guaranteeing ideal light yield.

Parameters

| Parameter | Specification |

|---|---|

| Material | Aluminum Alloy (ADC12, A356) |

| Surface Finish | Sand-blasted, Anodized |

| Ingress Protection | IP66/IP67 |

| Impact Resistance | IK10 |

| Temperature Range | -40°C to +60°C |

| Certification | ATEX, IECEx, UL |

| Customization | Available |

Product details pictures

Applications

- Oil and gas facilities

- Chemical processing plants

- Mining operations

- Marine environments

- Hazardous manufacturing areas

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been a trusted name in precision casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, is equipped with advanced machinery, ensuring high-quality production. We specialize in aluminum combination, copper amalgam, and stainless steel castings, serving worldwide car, mechanical gear, and apparatus fabricating segments. Our commitment to development and quality has made us a favored accomplice for customized metal parts around the world.

Why Choose Us?

- Expertise: 24 years of experience in precision casting

- Quality Assurance: ISO 9001 certified with strict quality control measures

- Customization: Tailored solutions to meet specific requirements

- Advanced Technology: State-of-the-art equipment for precise manufacturing

- Global Compliance: Products meet international safety standards

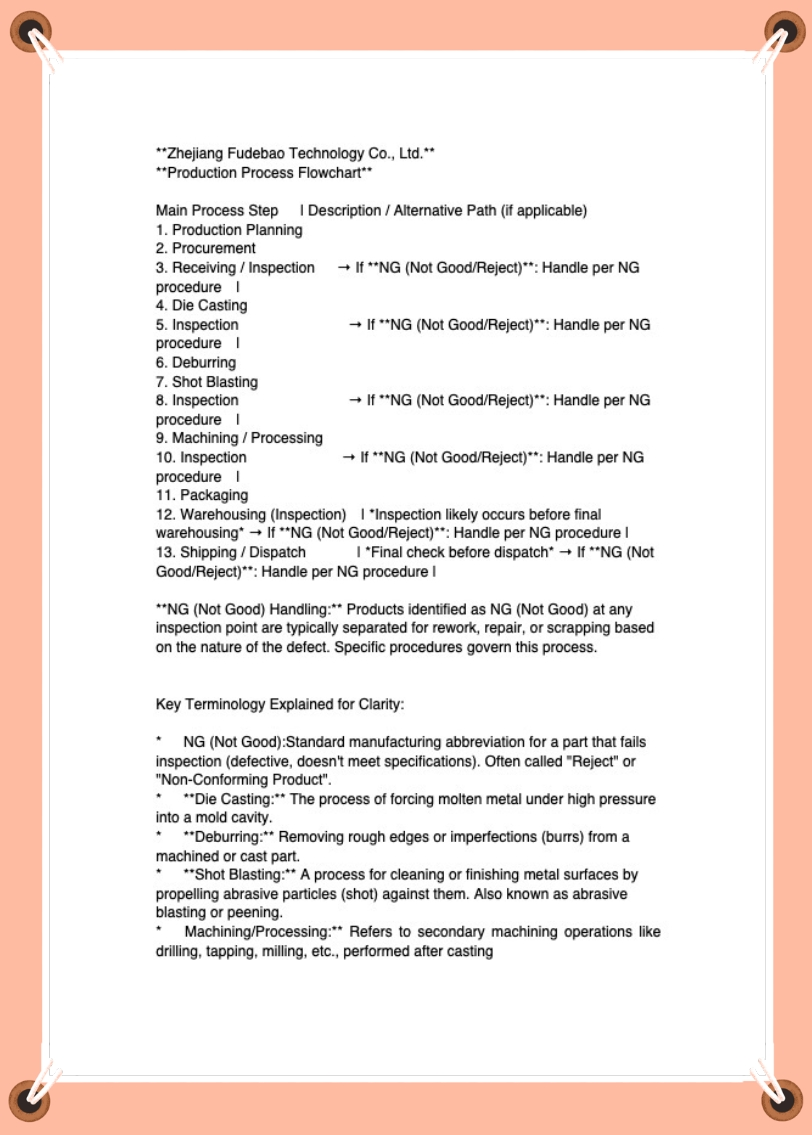

Production Process

- 3D Design and Modeling

- Pattern Making

- Mold Preparation

- Casting

- Heat Treatment

- Machining

- Surface Treatment

- Quality Inspection

- Packaging and Shipping

Certificates

- ISO 9001:2015

- ATEX Certification

- IECEx Certification

- UL Listing

Packaging and Shipping

- Custom packaging to ensure product protection

- Global shipping with tracking

- Flexible delivery options to meet your timeline

FAQ

Q1: What is the minimum order quantity for theproducts?

A1: Our minimum order quantity is 100 pieces, but we can discuss smaller quantities for sample orders.

Q2: Can you provide custom designs for the products?

A2: Yes, we offer customization services. Please send us your technical drawings or requirements for a quote.

Q3: What is the lead time for the products?

A3: Standard lead time is 3-4 weeks, but this can vary based on order quantity and specifications.

Q4: Do your products meet international safety standards?

A4: Yes, our products comply with ATEX, IECEx, and UL standards, ensuring safety in hazardous environments worldwide.

Contact Us

Ready to enhance your safety with our high-quality explosion-proof lamp shell castings? Contact us today for a quote or to discuss your specific requirements.

Email: hank.shen@fdbcasting.com

Trust Zhejiang Fudebao Technology Co., Ltd. for durable, certified products that protect your equipment and personnel in the most challenging environments.

YOU MAY LIKE

_1756360265131.webp)