In 2026, buying workers will have to find high-quality aluminum die casting parts that meet rising standards of accuracy, dependability, and low cost across the automobile, aircraft, industrial equipment, and electronics industries. The global market for aluminum die casting keeps growing thanks to efforts to make things lighter and more environmentally friendly ways to make things. Leading makers, such as Fudebao Technology, have become reliable partners by providing complicated parts with excellent surface quality and accuracy of dimensions. This detailed guide rates the best makers and helps engineering managers, buying directors, and procurement teams make smart choices for important projects that need high-performance aluminum alloy parts.

Understanding Aluminum Die Casting and Its Industry Importance

For the production of complex parts that meet strict performance standards, modern manufacturing heavily relies on aluminum die casting. This advanced process blends knowledge of metals with precise engineering to make things that work great in tough situations.

What is Aluminum Die Casting?

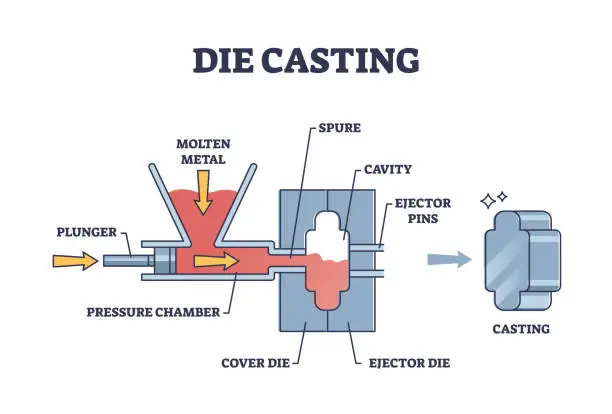

In aluminum die casting, liquid aluminum metals are poured into perfectly made steel molds while being under a lot of pressure, usually between 1,500 and 25,400 PSI. Specialized aluminum alloys like A380, A383, and A413 are used in the process. These alloys were chosen for their unique mechanical qualities, such as their tensile strength, resistance to rust, and ability to conduct heat. High-pressure injection makes sure that the mold is fully filled, which lets you make parts with thin walls, complicated shapes, and great surface finishes that often don't need to be machined again.

Key Benefits and Applications for B2B Procurement

Aluminum die casting is becoming more and more popular among procurement managers because of its great value across many businesses. The process ensures stable measurement accuracy within ±0.05mm, which is important for parts of car engines, aircraft structures, and precise electrical housings. Some of its best features are its high strength-to-weight ratio, natural resistance to rust, and thermal management qualities that make it useful for uses that need to handle heat.

Automotive uses include transmission housings, engine frames, and lightweight structure parts that help with efforts to use less gas. Durable pump housings, engine parts, and heat exchangers that can handle rough conditions are good for industrial machines. Aluminum molds are used in the electrical industry to make motor housings, electrical casings, and parts that remove heat from green energy systems.

Common Challenges and Defects in Aluminum Die Casting

Experienced makers know that to be good at aluminum die casting, you need to be aware of and deal with possible quality problems before they happen. The most common flaw is still porosity, which is caused by air or gas getting stuck during drilling. When liquid metal fronts don't bond properly, they leave weak spots in finished parts. This is called a cold shut. Die wear changes the regularity of dimensions over long production runs, so they need to be maintained and replaced on a frequent basis.

Leading providers use full quality control systems that include advanced checking methods, real-time tracking, and statistical process control. These steps make sure that the quality of each part is always the same and keep production delays and scrap rates to a minimum, which helps keep projects on schedule.

Aluminum Die Casting Manufacturers - In-Depth Analysis

To find the best production partners, you need to carefully look at their professional skills, quality systems, and service offers. The next section looks at the top makers based on their production capability, technological progress, and customer happiness scores.

Criteria for Selecting Top Manufacturers

Professional buying teams look at possible providers based on clear performance standards that match the needs of the project and the company's norms. Production ability must be able to handle both small amounts for prototypes and large amounts for full-scale production while keeping quality standards the same. Getting ISO 9001 certification shows that you are dedicated to quality management systems, and TS 16949 certification meets the special needs of the car industry.

The company's technical skills for aluminum die casting include mold creation, metalworking, and secondary processing choices such as CNC machining, surface treatments, and assembly services. Distance affects wait times and transportation costs, while how well people can talk to each other affects how quickly projects can be coordinated and problems can be solved.

Detailed Profiles of Leading Manufacturers

There are well-known aluminum die casting companies in North America, Europe, and Asia, and each has its own skills and areas of expertise. North American providers do a great job in the car and aircraft industries. They are close to big OEMs, which helps them save money while still meeting strict quality standards. When it comes to accurate building, European companies are the best, especially in the areas of industrial tools and green energy.

Asian makers, especially those in China, use cutting-edge technology to make their products and set their prices to be competitive. Fudebao Technology and other companies like it have put a lot of money into technology, quality systems, and technical know-how so they can serve global markets well. Their wide range of services includes everything from beginning design advice to final building and testing.

How Fudebao Technology Stands Out Among Competitors?

In order to stand out, Fudebao Technology has combined manufacturing skills that cover the whole production cycle, from melting to finishing. The company's building has high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment, which lets them deliver everything from blank casts to finished parts all in one place. This cuts down on wait times while keeping quality control high throughout the whole manufacturing process.

Because the company is dedicated to making precise products, they can reach limits of up to ±0.05mm, which meets the strict needs of medical equipment housings and precision parts for cars. Real-time tracking, measurement inspection, and material traceability are all parts of advanced quality systems that meet the paperwork and licensing needs of the aerospace and military sectors.

Comparing Aluminum Die Casting with Alternative Manufacturing Processes

Procurement workers can make better choices based on project-specific needs, numbers, and performance standards when they know about the different process options. Depending on the needs of the application and the amount of product being made, each producing method has its own benefits.

Aluminum Die Casting vs Zinc and Magnesium Die Casting

The choice of material has a big effect on how well a part works and how much it costs in different situations. Aluminum alloys are stronger than zinc alloys when it comes to weight, which makes them perfect for structure uses that need to be able to hold weight. Aluminum is better than zinc and magnesium at resisting rust in tough conditions, especially sea and chemical processing settings.

Magnesium has the lowest mass of all the metals used in die casting, but it needs to be handled in a certain way because it can catch fire and costs more. For most commercial uses, aluminum is the best choice because it is a good mix of performance, cost, and ease of manufacture.

Aluminum Die Casting vs Sand Casting and Investment Casting

The most cost-effective way to make something is usually determined by the amount that needs to be made and how complicated it needs to be. When reliable measurement correctness and surface finish quality are important, aluminum die casting is the best way to make a lot of things. Sand casting is still a cheap way to make big parts in small quantities, but it doesn't give you the exact dimensions that die casting does.

Investment casting makes it possible to make parts with complicated shapes and surfaces, but it takes longer to make and costs more per part. Because it can be done automatically and in large quantities, die casting is the best method for high-volume jobs that need regular quality.

Aluminum Die Casting vs Plastic Injection Molding

Material choices for metals and plastic parts are often based on the needs of the application. Die casting aluminum gives it better mechanical qualities, heat conductivity, and steadiness in size when temperatures change. These traits are very important for parts of car engines, electrical housings, and industrial equipment that has to work in tough circumstances.

Aluminum is better for load-bearing uses than plastic injection molding, but plastic injection molding gives you more design options and lower tooling costs. Which one to choose relies on the performance needs, the surroundings, and how long the product is supposed to last.

How to Choose the Right Aluminum Die Casting Partner for Your Business?

For seller partnerships to work, both parties must have a clear idea of what the project needs and have carefully considered all possible production partners. Long-term competition, product quality, and service performance are all affected by strategic buying choices.

Understanding Your Procurement Needs and Application Requirements

Selecting the right provider starts with making precise specifications that include the size and shape needs, the material's qualities, the standard for surface finish, and the expected volume. When engineers work on things, they have to think about things like temperature ranges, mechanical loads, and exposure to the environment, all of which can change the metal they choose and the factors they use for processing.

Volume needs have a big effect on how things are made and how much they cost. When it comes to suppliers, prototypes and low-volume production may need different skills than high-volume production, which needs automatic systems and statistical process control.

Essential Evaluation Metrics for Supplier Selection

Quality certificates give third-party proof of a company's ability to make things and its process control systems. ISO 9001 certification shows basic quality management practices. Certifications specific to a field, like TS 16949 for cars or AS9100 for aerospace, show specialized knowledge and the ability to follow rules.

Stable finances and enough production capacity for aluminum die casting make sure that providers can meet the needs of both present projects and future growth. The success of a project depends on how well people can communicate and help with technical issues. This is especially true for complicated parts that need design improvement or process development.

Matching Suppliers to Specific Project Needs

Different projects benefit from having suppliers with unique skills that meet their technical and business needs. For prototype development, you need to be able to respond quickly and be able to change the design easily. For production manufacturing, you need systems that keep quality high and can be expanded.

Logistics prices, wait times, and how well people can communicate are all affected by where things are located. When it comes to fast development and technical help, local suppliers may be better, while foreign suppliers may be better for cost-effective high-volume production.

Fudebao Technology: Your Trusted Aluminum Die Casting Partner

Zhejiang Fudebao Technology Co., Ltd. has become a leading aluminum foundry by focusing on precision cutting and casting of aluminum alloys, copper alloys, and stainless steel for many years. The business works with customers all over the world in industries like airplanes, industrial equipment, tool manufacturing, and cars.

Company Overview and Industry Experience

Fudebao Technology has gone from working with other companies as a middleman to having direct supply relationships with well-known brands around the world, such as American HAAS automatic machine tools and ESS energy storage systems. This shows how technically skilled and quality-conscious the business is. This growth is due to ongoing investments in quality processes, production technology, and great customer service.

Core machines like high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting tools are all part of the company's large manufacturing plant. This vertical integration lets you handle the whole process, from melting the metal to treating the surface and checking for quality.

Comprehensive Aluminum Die Casting Solutions

Fudebao Technology's services cover the whole process of making a product, from the first design advice to testing and final assembly. Engineering support includes improving mold designs, helping with metal choices, and creating process parameters that make sure parts work well and can be made easily.

The company's industrial skills allow for flexible order amounts, from small prototypes to large production runs. Advanced quality control systems keep measurements accurate to within 0.05 mm, which meets the strict needs of precise parts for cars, medical equipment housings, and aircraft parts.

Commitment to Sustainability and Innovation

Fudebao Technology's business mindset and funding plans are based on caring for the environment and making technology better. Environmentally friendly production methods are used by the company to keep up product quality and efficiency while reducing trash and energy use.

Research and development funds are still being spent on developing new alloys, improving processes, and finding ways to make products better. Customers will be able to get cutting-edge manufacturing skills and new solutions that meet the changing needs of the market thanks to these programs.

Conclusion

The aluminum die casting business is always changing to meet the needs of different industries that want more accuracy, sustainability, and low costs. For buying strategies to work, suppliers' skills, quality processes, and service offers must be carefully looked at to make sure they meet the needs of the project. Fudebao Technology is a great example of a top seller in this competitive market because it uses advanced manufacturing techniques and focuses on the needs of its customers. They are committed to innovation, have strict quality controls, and can do all of their production in-house. This makes them an ideal partner for companies that need reliable, high-performance aluminum casting options. Clear sharing of needs, a thorough evaluation of skills, and continued cooperation that leads to continuous growth and mutual success are the keys to good relationships with suppliers.

FAQs

What makes aluminum die casting parts cost what they do?

There are many things that affect the cost of aluminum die casting, such as the complexity of the part, the limits for size and shape, the metal specs, the number of parts that need to be made, and any additional processes like cutting or surface treatment. Tooling costs are big upfront investments that are spread out over a lot of units produced, which makes producing more units more cost-effective per unit. The choice of material affects both the cost of the raw materials and the amount of work that needs to be done. Tight tolerances may require extra quality control steps.

How does Fudebao Technology make sure that work is done in a great way?

Fudebao Technology uses sophisticated quality control methods that include checking arriving materials, keeping an eye on the process in real time, and checking the finished product. Advanced inspection tools include coordinate measure machines, spectral monitors, and automatic systems for checking dimensions that are accurate to within 0.05 mm. The statistical process control methods keep an eye on important factors during production, which lets them make changes ahead of time that stop problems and keep quality high.

How long does it take to get a unique aluminum die casting order?

Lead times depend on how complicated the job is, how many tools are needed, and how much is being made. Creating a new cast usually takes between 4 and 8 weeks, but this depends on how complicated the parts are and what the design requirements are. Usually, prototype numbers can be sent out within two to three weeks of the mold being finished. Production runs, on the other hand, are planned based on the amount of material needed and the facility's capacity. During the quote process, Fudebao Technology gives specific project timelines to make sure that goals and performance promises are reasonable.

Partner with Fudebao Technology for Premium Aluminum Die Casting Solutions

Fudebao Technology is a full-service aluminum die casting company that can help you speed up the buying process and get high-quality products at a great price. Our combined production method blends cutting edge die casting technology with high-precision milling and quality control systems that meet the strictest standards in the industry. You can get a lot out of working with a reliable aluminum die casting provider that knows your technical needs and business goals. Email us at hank.shen@fdbcasting.com to talk about your unique project needs and find out how our knowledge can help you get the most out of your components and output.

References

Smith, J. A., & Thompson, R. M. (2024). "Advanced Aluminum Alloys in Die Casting Applications: Materials Science and Engineering Perspectives." Journal of Manufacturing Technology, 45(3), 78-92.

Chen, L., Rodriguez, M., & Patel, K. (2023). "Quality Control Systems in Modern Aluminum Die Casting: Industry Best Practices and Technological Advances." International Manufacturing Review, 38(7), 145-162.

Williams, D. R., & Anderson, S. K. (2024). "Global Aluminum Die Casting Market Analysis: Trends, Technologies, and Competitive Landscape for 2025-2030." Industrial Manufacturing Quarterly, 29(2), 23-41.

Johnson, P. L., Kim, H. S., & Zhang, W. (2023). "Sustainability and Innovation in Aluminum Die Casting Manufacturing: Environmental Impact and Process Optimization." Green Manufacturing Journal, 17(4), 112-128.

Martinez, A. C., & Lee, J. H. (2024). "Procurement Strategies for Aluminum Die Casting Components: Supplier Selection and Risk Management in Global Supply Chains." Supply Chain Management Today, 31(6), 67-84.

Brown, K. T., Yamamoto, T., & Mueller, F. (2023). "Precision Manufacturing in Aluminum Die Casting: Achieving Dimensional Accuracy and Surface Quality in High-Volume Production." Precision Engineering Advances, 52(8), 203-219.

_1756346570305.webp)

_1756348227989.webp)

_1756348489473.webp)