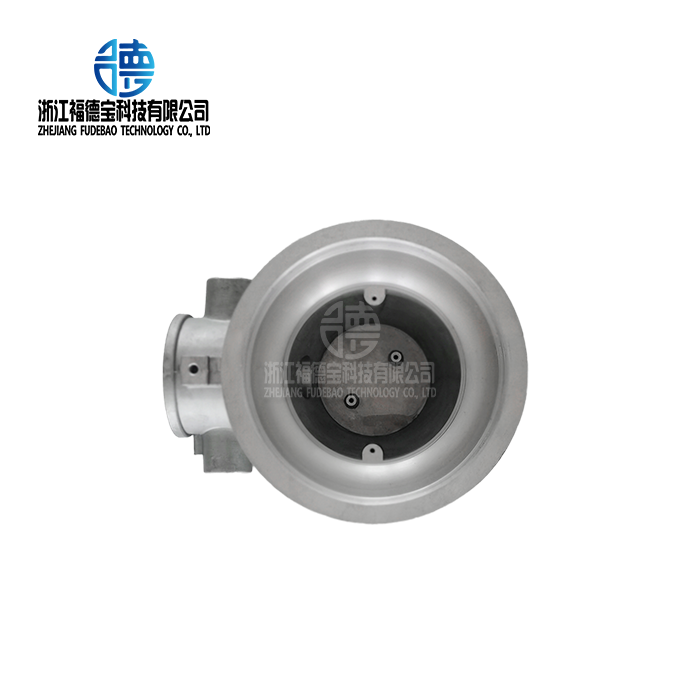

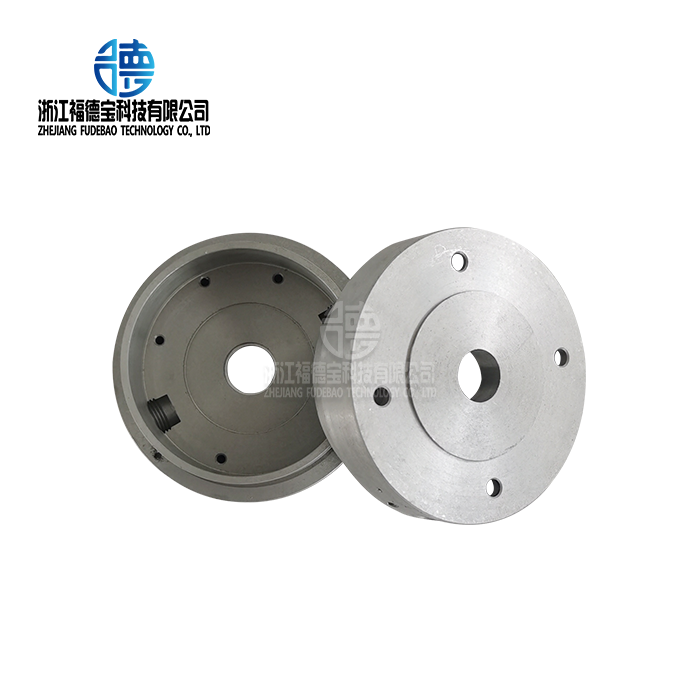

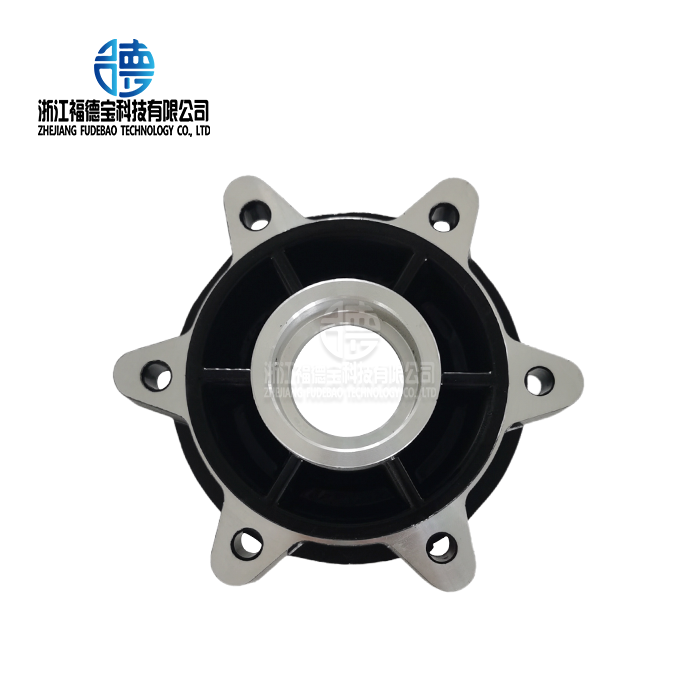

Bracket aluminum casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:aluminum die casting

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Bracket Aluminum Casting: Precision-Engineered Solutions for Industrial Applications

At Zhejiang Fudebao Technology Co., Ltd., we specialize in manufacturing high-quality bracket aluminum castings for diverse industrial needs. With 24 years of expertise in precision casting, we deliver superior products that meet the exacting standards of automotive, aerospace, and industrial machinery sectors. Our products combine lightweight durability with precise engineering, making them ideal for critical structural and mechanical assemblies.

Product Description

Our products are meticulously crafted using advanced low-pressure and sand casting techniques. These brackets offer exceptional strength-to-weight ratios, corrosion resistance, and thermal conductivity. Customizable to your specifications, our products ensure optimal performance in demanding industrial environments.

Parameters

| Parameter | Specification |

|---|---|

| Material | AL6061, AL7075, or custom alloys |

| Tensile Strength | ≥280 MPa |

| Yield Strength | ≥240 MPa |

| Elongation | >7% |

| Surface Finish | Ra ≤0.8μm |

| Dimensional Tolerance | ±0.05mm |

| Weight Range | 0.5 - 50 kg |

| Production Capacity | Up to 100,000 pieces/month |

Applications

Our bracket aluminum castings find extensive use in:

- Automotive: Engine mounts, chassis components

- Aerospace: Structural supports, equipment housings

- Industrial Machinery: Robot arm joints, conveyor systems

- Renewable Energy: Wind turbine components, solar panel frames

- Construction Equipment: Hydraulic system brackets, control panel mounts

Company Profile

Zhejiang Fudebao Technology Co., Ltd. has been a leader in precision metal casting since 2001. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, houses advanced equipment for the entire casting process. We prioritize innovation, investing 8% annually in R&D to stay at the forefront of casting technology. Our commitment to quality and customer satisfaction has made us a preferred partner for global industrial metal parts customization.

Why Choose Us?

- 24 years of specialized experience in precision casting

- ISO 9001 and IATF 16949 certified quality management system

- Advanced manufacturing capabilities with ±0.05mm accuracy

- Flexible production for both small batches and high-volume orders

- Comprehensive services from design optimization to after-sales support

- Cost-effective solutions without compromising on quality

Production Process

- CAD/CAM Design and Optimization

- Prototype Development and Testing

- Mold Creation

- Aluminum Alloy Preparation

- Casting (Low-Pressure or Sand Casting)

- Heat Treatment

- CNC Machining for Precision Finishing

- Quality Inspection and Testing

- Surface Treatment (if required)

- Packaging and Shipping

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949:2016 Automotive Quality Management

- ISO 14001:2015 Environmental Management System

- OHSAS 18001 Occupational Health and Safety

Packaging and Shipping

We ensure secure packaging tailored to your product requirements:

- Custom-designed cartons or pallets for maximum protection

- Vacuum-sealed options for corrosion prevention

- Bulk packaging available for large orders

- Global shipping with tracking and insurance options

FAQ

- Q: What is the minimum order quantity for the products?

A: We offer flexible MOQs starting from as low as 50 pieces, depending on the complexity of the design. - Q: Can you provide custom designs for the products?

A: Absolutely! We offer full customization services, working from your drawings or collaborating on new designs to meet your specific needs. - Q: What is the lead time for a typical order of the products?

A: Lead times vary based on order volume and complexity, but typically range from 3-6 weeks. We also offer expedited services for urgent needs. - Q: Do you offer any surface treatment options for the aluminum brackets?

A: Yes, we provide various surface treatments including anodizing, powder coating, and electroplating to enhance durability and aesthetics.

Contact Us

Ready to elevate your industrial applications with our premium bracket aluminum castings? Contact our expert team today for a personalized quotation and discover how we can optimize your manufacturing process.

Email: hank.shen@fdbcasting.com

Let Zhejiang Fudebao Technology Co., Ltd. be your trusted partner in precision aluminum casting solutions.

_1756346570305.webp)

_1756345858191.webp)

_1756346205762.webp)

_1756346421748.webp)