Choosing a Reliable Aluminum Die Casting Manufacturer

2026-01-27

To find a reliable aluminum die casting manufacturer, you should make sure they have the right technical skills, quality processes, and production capacity to meet your business needs. It is very exact and consistent to use aluminum die casting, which is why it is used so often in electrical housings, aerospace parts, industrial machinery, and car parts. For relationships to work, makers must be able to do everything, from making prototypes to mass production, using both new technology and years of experience. If you want to find the best manufacturing partner for your needs, you should look for one with quality licenses, understanding of the materials, and a history of on-time deliveries.

Understanding Aluminum Die Casting: Key Concepts for Procurement Managers

For the aluminum die casting process, very hot aluminum alloys are pressed hard into steel molds that have been carefully made for this purpose. The measurements are very exact, and the shapes are very complicated. When things are made this way, they have a smooth surface, tight limits (usually between ±0.1mm and ±0.3mm), and good mechanical properties. Buying managers can figure out what sellers can do and make smart decisions about part specs when they know these basic technical terms.

Material Properties and Alloy Selection

When used in die casting, aluminum metals are very strong for their weight, don't rust, and can move heat around well. Some metals that are used often are A380, A383, and A413. These are the things that make each one useful for different jobs. A380 is good for making frames and housings for cars because it is very flexible and doesn't change shape much. The A413 grade is better for electrical uses because it doesn't rust, and the A383 grade is better for die-filling thin-walled parts.

Quality Control and Process Standards

These days, die casting plants use full quality control systems that have automatic inspection systems, statistical process control, and coordinate measuring tools. Leading makers keep their ISO 9001 certification up to date. They also often have other certifications, such as IATF 16949 for parts used in cars or AS9100 for parts used in spacecraft. These licenses show that the business cares about quality and keeping an eye on the production process.

Evaluating and Comparing Aluminum Die Casting Manufacturing Options

When comparing different ways to make things, aluminum die casting has clear benefits over other methods in some situations. When procurement teams understand these similarities, they can choose the manufacturing method that meets their needs technically and at the lowest cost.

Die Casting vs. Sand Casting Performance

When compared to sand casting, aluminum die casting gives a better surface finish and more accurate measurements, and it eliminates the need for many secondary finishing steps. For low-volume needs, sand casting has lower tooling costs. For mid to high-volume needs, die casting has better material properties and faster production rates. Die casting often gets rid of the need for lengthy finishing steps because it improves the quality of the surface. This lowers the overall cost of production.

Investment vs. Operational Cost Analysis

Die casting needs more money to buy the tools up front, but it costs less per part when more than 1,000 are made each year. The process can make cycles as short as 30 to 60 seconds for small to medium-sized parts, which saves a lot of money on labor costs compared to cutting. These operational efficiencies are especially useful in the auto and industrial sectors where quality needs to be maintained across big production runs.

Geographic Considerations and Supply Chain Factors

The benefits of global producers depend on where they are located, how easy it is to get technology, and how well they can handle logistics. Asian manufacturers often offer low prices and advanced automation, while North American and European providers are closer and have more specialized certifications. The best geographic sourcing approach for each application can be found by looking at transportation prices, lead times, and regulatory compliance requirements.

How to Choose a Reliable Aluminum Die Casting Manufacturer: A Decision Support Approach?

To find the best manufacturing partner, you need to carefully look at their technical skills, quality processes, and business practices. This structured method helps purchasing teams find sellers who can meet their needs and help them reach their long-term goals.

Technical Capability Assessment

The first step in evaluating a manufacturer's ability to make things is to look at its equipment's capacity. This includes machine tonnage ranges, automation levels, and the ability to do extra processing. Integrated facilities let advanced makers do casting, machining, and surface treatment all in one place. This cuts down on handling costs and makes quality control better. The ability to make prototypes shows how knowledgeable a company is in engineering and how well they can help with design improvement during the product development stages.

Quality System Verification

Comprehensive quality management includes more than just getting basic certifications. It also includes validating processes, vetting suppliers, and starting programs for continuous growth. To make sure consistent performance, reliable manufacturers keep thorough records of their processes, use preventative maintenance programs, and do regular capability studies. The results of customer audits, quality metrics, and reaction times for corrective actions can teach us a lot about operational excellence.

Production Capacity and Flexibility

To make sure that deliveries are made on time, evaluating production capacity means looking at both how much is being used now and how much can be added. Flexible makers can adapt to changing demand patterns by using effective scheduling systems and managing their workers in a way that can be scaled up or down. Being able to respond to emergencies and having backup plans show that you care about the dependability of the supply chain during unplanned disruptions.

The most trustworthy partners keep lines of communication open and give regular updates on the state of production, quality metrics, and possible problems. This proactive method makes it possible for people to work together to solve problems and builds trust in long-term supply relationships.

Practical Tips for Working Effectively with Aluminum Die Casting Manufacturers

To build a good working relationship with aluminum die casting suppliers, you need to communicate clearly, set clear goals, and work together to solve problems. These organizational best practices help make sure that projects go well and that partnerships are strong.

Design Collaboration and Technical Support

Partnerships that work well start during the planning phase, when experienced manufacturers can give helpful advice on how to make the part better, what materials to use, and whether the part can be made. Design for Manufacturing (DFM) reviews help find problems early on, which cuts down on development time and costs. Discussions between engineers who work together often show ways to cut costs by combining parts or improving their shapes without affecting how they work.

Communication Protocols and Project Management

During the development and production stages of a project, all stakeholders are kept informed through standard reporting formats and regular contact schedules. Weekly status talks, reviews of key milestones, and quality reports make it easy to see how things are going and what might be a problem. Setting up clear ways for problems to be escalated helps solve problems quickly, before they affect delivery times or quality performance.

Contract Terms and Risk Management

Comprehensive agreements should cover things like shipping requirements, quality standards, protecting intellectual property, and making plans for what to do if something goes wrong. During production, misunderstandings are avoided by making clear the tolerances for dimensions, the requirements for surface finish, and the inspection processes. Payment terms, warranty conditions, and limits on responsibility protect both parties and encourage high performance.

Building trust through consistent performance and open communication is the key to long-term relationships that are good for both customers and manufacturers. Reviewing a business on a regular basis gives you a chance to talk about ways to improve performance, plan for growth, and get new technologies that make you more competitive.

Our Commitment to Your Aluminum Die Casting Needs

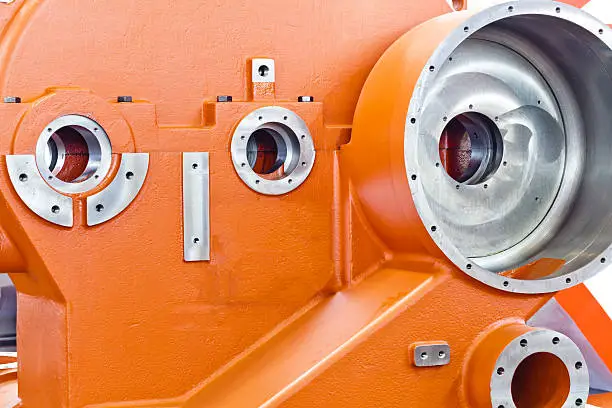

Zhejiang Fudebao Technology Co., Ltd. is the best aluminum foundry in China. They use modern manufacturing techniques and full quality systems to serve customers in the aerospace, automotive, and industrial equipment markets around the world. Our integrated building has high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment. This lets us make everything from melting to finishing, and the accuracy of our work can reach ±0.05mm.

Comprehensive Manufacturing Capabilities

Our industrial knowledge covers the whole process, from getting the melt ready in the beginning to finishing the surface and inspecting it. The building has cutting-edge tools for casting aluminum alloy, copper alloy, and stainless steel, and it can also do precise machining, which gets rid of the need for multiple sources. This unified method cuts down on wait times, makes quality control better, and saves money by streamlining logistics.

Industry-Specific Solutions

We know that different businesses have different needs, so we make sure that our services fit those needs. Our PPAP paperwork skills and attention to detail when it comes to sizes are very useful for automotive clients. Manufacturers of industrial equipment depend on our knowledge of tough materials and heat-resistant alloys for tough jobs. Customers in the electrical industry appreciate how precisely we make housings and heat-dissipation parts with smooth surfaces.

Quality Assurance and Certification

Our quality management system includes thorough inspection procedures, statistical process control, and ongoing efforts to make things better. This makes sure that all of our production batches perform at the same level. Throughout the manufacturing process, skilled quality workers and advanced measuring tools make sure that the product meets the requirements. International names, such as American HAAS automation machine tools and ESS energy storage systems, understand how important it is to always do the best job possible.

Fudebao Technology is a great partner for businesses that need reliable aluminum die casting options because they have the technical know-how, manufacturing flexibility, and customer-focused service. Our experienced engineering team works closely with customers to make designs better, cut costs, and get new goods to market faster.

Conclusion

Some things you should look at in an aluminum die casting manufacturer are their business practices, professional skills, and quality processes. This will help you get along with them for a long time. As part of the decision-making process, the communication protocols, certification levels, output capacity, and tools used for making the product are all looked at. Things like location and total cost are also thought about. To make procurement strategies work, they need to focus on suppliers who always do good work, offer collaborative engineering support, and have production skills that are flexible enough to change to changing market needs. It gives you an edge over other companies if you build strong relationships with manufacturers who have a lot of experience. This is because it improves product quality, cuts down on development time, and makes sure that your supply chain works reliably in a wide range of workplace settings.

FAQ

What factors have the biggest effect on the price of an aluminum die casting part?

In aluminum die casting, the main things that affect prices are the cost of materials, the difficulty of making the tools, the amount of production needed, and the need for secondary processing. Tooling costs are usually moderate to high, based on how complicated the part is and how many cavities it has. However, these costs are quickly covered by production volumes above 5,000 pieces. The prices of raw materials change with the market for aluminum, and extra steps like machining, surface treatment, and inspection raise the cost based on the needs of the standard.

For my purpose, how do I choose between CNC machining and aluminum die casting?

The best way to make something depends on how much it needs to be made, how complicated the shapes are, and how well the materials are used. Die casting is best for making more than 1,000 pieces a year with complicated internal geometries, while CNC machining is best for making few pieces that need a smooth surface or unusual metals. Die casting makes better use of materials and has faster cycle times. Machining, on the other hand, gives you more design options and tighter tolerances for certain measurements.

How long should I wait for a lead time from a reliable aluminum die casting company?

Lead times are usually between 4 and 8 weeks for developing tools, 2 to 3 weeks for making test samples, and 3 to 6 weeks for mass production, but this depends on the amount and complexity of the work. Rush orders may get delivered faster if the tooling is made faster or if the mold is changed. Reliable makers give detailed information about schedules during the quotation phase and keep extra capacity to meet urgent needs without lowering quality standards.

How can I make sure that a company can deliver quality goods before I place an order?

To figure out how well a company can make things, ask for quality certifications, customer references, and facility audit records. Look over the records for process control, inspection methods, and the calibration of measuring tools. Evaluation of a sample part shows directly how accurate the dimensions are, how good the surface finish is, and how consistent the part is. A lot of manufacturers let you take virtual tours of their facilities or watch thorough presentations that show how their high-tech equipment and quality control systems work.

Partner with Fudebao Technology for Superior Aluminum Die Casting Solutions

Find out how Zhejiang Fudebao Technology can turn your manufacturing needs into precisely made aluminum die casting parts that are better than the norm in the industry. Our wide range of skills, from making prototypes to producing large quantities, makes sure that we can easily meet your supply chain goals. Email our engineering team at hank.shen@fdbcasting.com to talk about the specifics of your application needs and get full technical proposals. As a reliable provider of aluminum die castings, we give your business a competitive edge through cutting-edge manufacturing technology, strict quality control, and quick customer service.

References

American Foundry Society. "Die Casting Process Control and Quality Management Systems." Foundry Management & Technology, 2023.

Chen, L. and Roberts, M. "Aluminum Alloy Selection Criteria for High-Performance Die Casting Applications." International Journal of Manufacturing Engineering, 2023.

European Aluminum Association. "Sustainability and Performance Benefits of Aluminum Die Casting in Automotive Applications." Industry Report, 2023.

Johnson, R. "Cost Analysis and Process Optimization in Modern Die Casting Operations." Manufacturing Technology Review, 2023.

Smith, K. and Thompson, J. "Quality Standards and Certification Requirements for Global Die Casting Suppliers." Industrial Manufacturing Quarterly, 2023.

Zhang, H. "Advanced Manufacturing Technologies in Precision Die Casting: Equipment and Process Innovations." International Manufacturing Technology Conference Proceedings, 2023.

YOU MAY LIKE

_1756348356531.webp)