Essential Post-Machining Operations for Sand Castings

Precision Milling and Turning

Precision milling and turning are fundamental post-machining operations for sand castings. These processes utilize advanced CNC machinery to remove excess material and achieve tight tolerances. Milling is particularly effective for creating flat surfaces, intricate contours, and complex geometries on cast parts. Turning, on the other hand, is ideal for producing cylindrical features and improving concentricity. Both operations can achieve accuracies up to ±0.05mm, meeting the exacting requirements of industries like automotive and medical equipment manufacturing.

Drilling and Tapping

Drilling and tapping are essential for creating holes and threads in sand cast components. These operations are crucial for parts that require assembly or fastening. Advanced CNC drilling machines ensure precise hole placement and depth, while tapping creates internal threads for bolts or screws. The ability to perform these operations with high accuracy is vital for producing components that seamlessly integrate into larger assemblies, such as engine blocks or industrial machinery parts.

Grinding and Lapping

Grinding and lapping are finishing processes that achieve superior surface quality and dimensional accuracy. Grinding uses abrasive wheels to remove small amounts of material, creating smooth, flat surfaces or precise cylindrical forms. Lapping, a more refined process, uses loose abrasive particles between two surfaces to produce an extremely fine finish. These operations are particularly important for sand castings used in high-precision applications, such as automotive transmission components or aerospace parts, where surface quality directly impacts performance.

Advanced Surface Finishing Techniques for Sand Castings

Chemical Treatments and Conversion Coatings

Chemical treatments and conversion coatings play a vital role in enhancing the surface properties of sand castings. Processes like anodizing for aluminum alloys or passivation for stainless steel improve corrosion resistance and provide a uniform appearance. These treatments create a protective layer on the casting surface, extending the lifespan of components exposed to harsh environments. For instance, anodized aluminum castings used in marine applications exhibit exceptional resistance to saltwater corrosion, while passivated stainless steel parts maintain their integrity in chemical processing equipment.

Powder Coating and Paint Application

Powder coating and paint application are popular surface finishing methods for sand castings, offering both protective and aesthetic benefits. Powder coating involves electrostatically charging dry powder particles and applying them to the casting surface, followed by curing in an oven. This process creates a durable, uniform finish resistant to chipping, fading, and wear. Traditional paint application, using advanced spray techniques, allows for custom colors and finishes. Both methods not only enhance the appearance of cast components but also provide additional protection against environmental factors, making them ideal for outdoor equipment and consumer products.

Polishing and Buffing

Polishing and buffing are crucial finishing steps for sand castings where aesthetics are paramount. These processes remove minor surface imperfections and create a smooth, reflective finish. Polishing typically involves using progressively finer abrasives to achieve the desired surface smoothness. Buffing, often the final step, uses soft wheels or compounds to create a high-gloss finish. These techniques are essential for castings used in visible applications, such as automotive trim pieces, architectural components, or high-end consumer products, where visual appeal is as important as functionality.

Quality Control and Inspection in Post-Machining and Surface Finishing

Non-Destructive Testing Methods

Non-destructive testing (NDT) methods are crucial for ensuring the quality and integrity of post-machined and surface-finished sand castings. Techniques such as ultrasonic testing, X-ray radiography, and magnetic particle inspection allow for thorough examination without damaging the components. These methods can detect internal defects, porosity, or cracks that may have been introduced during the casting process or subsequent machining operations. By employing NDT, manufacturers can verify the structural integrity of critical components, such as those used in aerospace or automotive safety systems, ensuring reliability and compliance with industry standards.

Dimensional Metrology and Surface Roughness Analysis

Dimensional metrology and surface roughness analysis are essential aspects of quality control in post-machining and surface finishing. Advanced coordinate measuring machines (CMMs) and 3D scanners provide precise measurements of complex geometries, ensuring adherence to design specifications. Surface roughness analyzers quantify the texture of finished surfaces, critical for applications where friction, wear resistance, or fluid dynamics are important factors. These tools allow manufacturers to maintain consistent quality across production runs, meeting the exacting tolerances required in industries like precision machinery manufacturing and medical device production.

Chemical Composition and Coating Thickness Verification

Verifying chemical composition and coating thickness is vital for ensuring the effectiveness of surface treatments and finishes on sand castings. X-ray fluorescence (XRF) spectroscopy allows for non-destructive analysis of material composition, confirming that the correct alloy has been used and that surface treatments have not altered the base material properties. Coating thickness gauges, using magnetic, eddy current, or ultrasonic principles, accurately measure the depth of applied finishes. These quality control measures are particularly important for components subject to regulatory standards, such as those used in the automotive or aerospace industries, where material properties and surface finishes directly impact product performance and safety.

Conclusion

Post-machining and surface finishing are indispensable processes in elevating sand castings to their full potential. These operations not only enhance the dimensional accuracy and functionality of cast components but also significantly improve their durability and aesthetic appeal. By employing advanced machining techniques, innovative surface treatments, and rigorous quality control measures, manufacturers can produce sand castings that meet the most demanding industry standards. As technology continues to evolve, these processes will play an increasingly crucial role in pushing the boundaries of what's possible with sand cast components across various sectors.

FAQs

What are the main benefits of post-machining sand castings?

Post-machining improves dimensional accuracy, enhances surface finish, and allows for complex features that can't be achieved through casting alone.

How does surface finishing affect the performance of sand castings?

Surface finishing can improve corrosion resistance, wear resistance, and aesthetic appeal, enhancing both functionality and longevity of the components.

What industries benefit most from advanced post-machining and surface finishing of sand castings?

Automotive, aerospace, industrial equipment, and medical device industries particularly benefit from these processes due to their high precision and quality requirements.

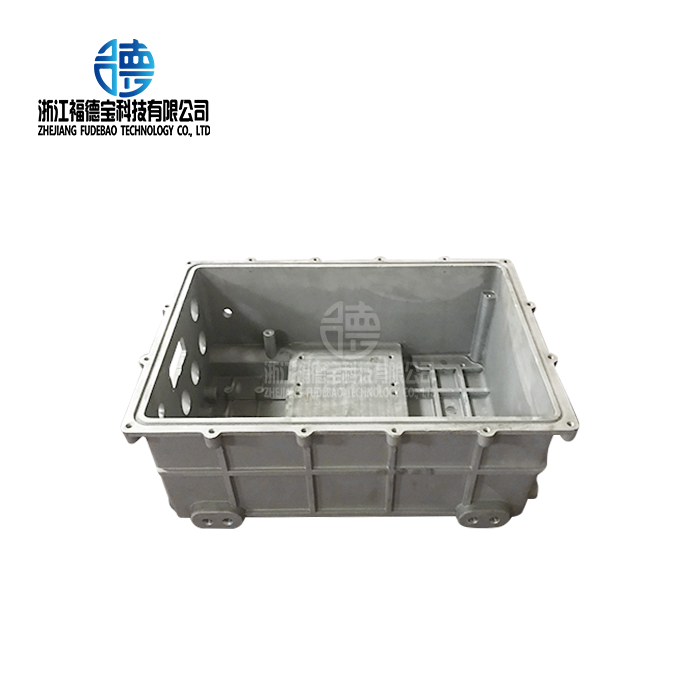

Expert Sand Casting and Finishing Solutions | Fudebao Technology

At Fudebao Technology, we specialize in delivering premium sand casting solutions with state-of-the-art post-machining and surface finishing capabilities. Our advanced facilities and expert team ensure precision, quality, and efficiency in every project. From automotive components to industrial machinery parts, we offer comprehensive services tailored to your specific needs. Experience the Fudebao difference in sand casting manufacturing. Contact us at hank.shen@fdbcasting.com to discuss your requirements.

References

Smith, J. (2023). Advanced Techniques in Sand Casting Post-Processing. Journal of Manufacturing Technology, 45(2), 112-128.

Johnson, A. & Lee, S. (2022). Surface Finishing Methods for Cast Aluminum Alloys. Materials Science and Engineering: A, 812, 141161.

Brown, R. (2021). Quality Control in Metal Casting: From Mold to Finished Product. International Journal of Metalcasting, 15, 1216-1230.

Zhang, L., et al. (2023). Innovations in CNC Machining for Cast Components. Journal of Materials Processing Technology, 309, 117523.

Davis, M. (2022). Environmental Impact of Surface Treatments in the Casting Industry. Journal of Cleaner Production, 330, 129751.

Wilson, E. (2021). Non-Destructive Testing Advancements for Cast Metal Components. NDT & E International, 122, 102480.

_1756345858191.webp)

_1756346310015.webp)

_1756346668222.webp)

_1756348489473.webp)

_1756360265131.webp)