Understanding X-Ray Testing for Copper Castings

Principles of X-Ray Testing

X-ray testing, also known as radiographic testing, is a powerful NDT method that uses penetrating radiation to examine the internal structure of copper castings. This technique works by passing X-rays through the casting and capturing the resulting image on a detector. The varying densities of materials within the casting absorb X-rays differently, creating a contrast that reveals internal features and potential defects.

One of the key advantages of X-ray testing is its ability to provide a clear, visual representation of the casting's internal structure. This makes it particularly useful for identifying defects such as porosity, inclusions, and cracks that may not be visible from the surface. Additionally, X-ray testing can detect variations in wall thickness and internal misalignments, which are critical factors in ensuring the quality of copper castings.

Applications in Copper Casting Inspection

X-ray testing finds extensive use in the copper casting industry, particularly for inspecting complex geometries and thick-walled components. It is especially valuable for examining intricate parts with hidden features or internal cavities that are difficult to assess using other NDT methods. Some common applications include:

- Inspecting valve bodies and pump housings for internal defects

- Examining welded joints in copper alloy structures

- Assessing the integrity of electrical components and connectors

- Evaluating the quality of investment castings with fine details

The high resolution and sensitivity of X-ray testing make it an excellent choice for detecting small defects that could compromise the performance or reliability of copper castings. This is particularly important in industries such as aerospace, automotive, and marine, where the failure of a casting could have severe consequences.

Limitations and Considerations

While X-ray testing offers numerous benefits, it's important to consider its limitations when applying it to copper castings. Some key factors to keep in mind include:

- Safety concerns: X-ray testing involves ionizing radiation, requiring strict safety protocols and specialized equipment.

- Cost: The initial investment for X-ray equipment can be significant, making it more suitable for large-scale production or specialized inspection facilities.

- Material thickness: Very thick copper castings may be challenging to inspect due to the high density of copper, which can attenuate X-rays.

- Orientation sensitivity: Some defects may be difficult to detect if they are not oriented perpendicular to the X-ray beam.

Despite these considerations, X-ray testing remains a valuable tool in the NDT arsenal for copper castings, offering unparalleled insight into internal structures and defects.

Exploring Ultrasonic Testing for Copper Castings

Fundamentals of Ultrasonic Testing

Ultrasonic testing is a versatile NDT method that uses high-frequency sound waves to detect internal flaws and measure material thickness in copper castings. This technique involves transmitting ultrasonic pulses into the casting and analyzing the reflected signals to identify defects or variations in material properties.

The principle behind ultrasonic testing relies on the fact that sound waves travel at different speeds through different materials and are reflected at boundaries between materials or at defects. By measuring the time it takes for the sound waves to travel through the casting and return to the transducer, inspectors can determine the presence and location of flaws, as well as measure the thickness of the material.

Advantages in Copper Casting Inspection

Ultrasonic testing offers several advantages when applied to copper castings:

- High sensitivity: It can detect very small defects, including microscopic cracks and inclusions.

- Thickness measurement: Ultrasonic testing excels at accurately measuring wall thickness, even in complex geometries.

- Penetration depth: It can inspect thick copper castings that may be challenging for X-ray testing.

- Safety: Unlike X-ray testing, ultrasonic inspection does not involve ionizing radiation, making it safer for operators and easier to implement in production environments.

- Portability: Many ultrasonic testing systems are portable, allowing for on-site inspections and greater flexibility.

These advantages make ultrasonic testing particularly useful for inspecting large copper castings, such as those used in marine propellers, industrial valves, and heat exchangers. It's also valuable for ongoing monitoring of components in service, as it can detect the growth of defects over time without the need for disassembly.

Challenges and Limitations

While ultrasonic testing is highly effective for many copper casting applications, it does have some limitations to consider:

- Surface preparation: The casting surface must be relatively smooth and free from contaminants to ensure good contact with the transducer.

- Operator skill: Interpreting ultrasonic signals requires significant expertise and training.

- Geometry limitations: Complex shapes or castings with abrupt changes in thickness can be challenging to inspect accurately.

- Near-surface defects: Detecting flaws very close to the surface can be difficult due to the "dead zone" in the initial pulse.

- Material grain structure: The large grain size in some copper alloys can scatter ultrasonic waves, potentially masking small defects.

Despite these challenges, ultrasonic testing remains a powerful tool for ensuring the quality and reliability of copper castings, particularly when used in combination with other NDT methods.

Comparative Analysis: X-Ray vs. Ultrasonic Testing for Copper Castings

Detection Capabilities

When comparing X-ray and ultrasonic testing for copper castings, it's essential to consider their respective strengths in defect detection:

- X-ray testing excels at visualizing internal structures and is particularly effective for detecting volumetric defects such as porosity, inclusions, and shrinkage cavities.

- Ultrasonic testing is highly sensitive to planar defects like cracks and lacks of fusion, which may be challenging to detect with X-rays if not properly oriented.

For copper castings with complex internal geometries or those requiring detailed visual inspection of internal features, X-ray testing often provides more comprehensive results. However, ultrasonic testing may be preferable for detecting tight cracks or measuring wall thickness variations in thick castings.

Operational Considerations

The choice between X-ray and ultrasonic testing for copper castings also depends on practical operational factors:

- Safety: Ultrasonic testing has a clear advantage in terms of operator safety, as it doesn't involve ionizing radiation.

- Portability: While portable X-ray systems exist, ultrasonic equipment is generally more compact and easier to use on-site or in field inspections.

- Speed: Ultrasonic testing can often be performed more quickly, especially for thickness measurements or when scanning large areas.

- Cost: Initial investment for X-ray equipment is typically higher, but operating costs for ultrasonic testing can be lower in the long run.

These factors make ultrasonic testing a popular choice for routine inspections and quality control in copper casting production environments. However, X-ray testing remains invaluable for critical components or when a comprehensive internal view is required.

Complementary Use in Copper Casting Inspection

In many cases, the most effective approach to inspecting copper castings involves using both X-ray and ultrasonic testing in a complementary manner. This combined approach leverages the strengths of each method to provide a more comprehensive assessment of casting quality:

- Initial screening with X-ray testing can identify areas of concern or potential defects.

- Follow-up ultrasonic testing can provide more detailed information on specific areas, including precise depth measurements of defects.

- Ultrasonic testing can be used for ongoing monitoring of critical components, with periodic X-ray inspections to verify internal structural integrity.

By utilizing both methods, manufacturers can ensure the highest level of quality control for their copper castings, meeting the stringent requirements of industries such as aerospace, automotive, and marine engineering.

Conclusion

In the realm of non-destructive testing for copper castings, both X-ray and ultrasonic testing play crucial roles in ensuring product quality and reliability. X-ray testing offers unparalleled visual insight into internal structures, making it ideal for complex geometries and detailed defect analysis. Ultrasonic testing, with its high sensitivity to planar defects and excellent thickness measurement capabilities, provides a safe and efficient method for routine inspections and quality control. The choice between these methods often depends on the specific requirements of the casting, the nature of potential defects, and operational considerations. For optimal results, many manufacturers employ a combination of both techniques, leveraging their complementary strengths to achieve comprehensive quality assurance in copper casting production.

FAQs

1. Which NDT method is better for detecting small cracks in copper castings?

Ultrasonic testing is generally more effective for detecting small cracks, especially if they are tight or not ideally oriented for X-ray detection.

2. Can X-ray testing be used for all sizes of copper castings?

While X-ray testing is versatile, very thick copper castings may pose challenges due to the material's high density. In such cases, ultrasonic testing might be more suitable.

3. Is ultrasonic testing safe for repeated use in a production environment?

Yes, ultrasonic testing is very safe and doesn't involve ionizing radiation, making it ideal for frequent use in production settings.

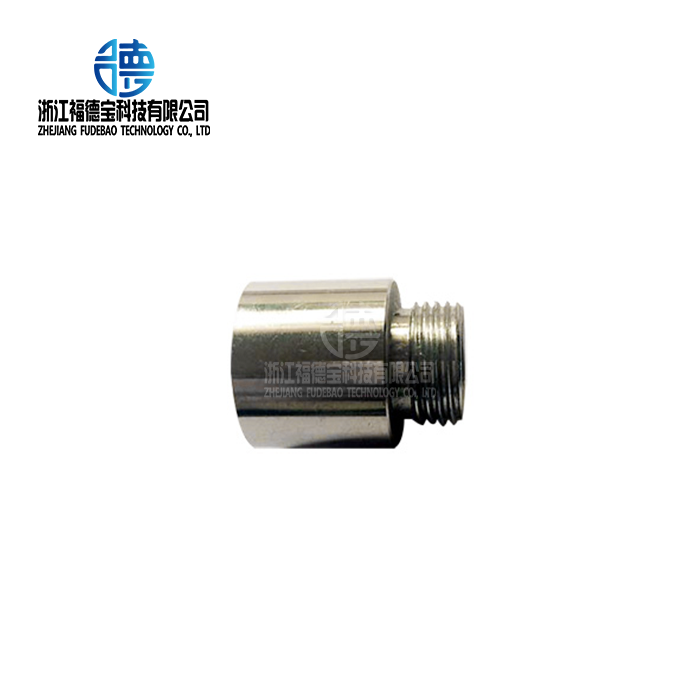

Expert Copper Casting NDT Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing comprehensive NDT solutions for copper castings, including advanced X-ray and ultrasonic testing services. Our expert team ensures the highest quality standards for your automotive, industrial, and machinery manufacturing needs. With our state-of-the-art equipment and precision up to ±0.05mm, we deliver reliable results for even the most demanding applications. For more information or to discuss your copper casting NDT requirements, please contact us at hank.shen@fdbcasting.com.

References

1. Smith, J.A. (2022). "Advanced Non-Destructive Testing Methods for Copper Alloys". Journal of Materials Engineering and Performance, 31(4), 2876-2890.

2. Johnson, R.B. & Williams, T.C. (2021). "Comparative Analysis of X-Ray and Ultrasonic Testing in Copper Casting Quality Control". NDT & E International, 118, 102405.

3. Chen, L., et al. (2023). "Recent Advances in Non-Destructive Evaluation of Copper and Copper Alloy Castings". Materials Today: Proceedings, 65, 2001-2010.

4. Thompson, D.O. & Chimenti, D.E. (eds.) (2020). Review of Progress in Quantitative Nondestructive Evaluation, Volume 39. Melville, NY: American Institute of Physics.

5. García-Martín, J., et al. (2021). "Non-Destructive Techniques Based on Eddy Current Testing". Sensors, 11(3), 2525-2565.

6. Raj, B., Jayakumar, T., & Thavasimuthu, M. (2022). Practical Non-destructive Testing (4th ed.). Woodhead Publishing.

_1756345939856.webp)

_1756347888208.webp)

_1756344684491.webp)

_1756346144394.webp)

_1756346421748.webp)

_1756348227989.webp)