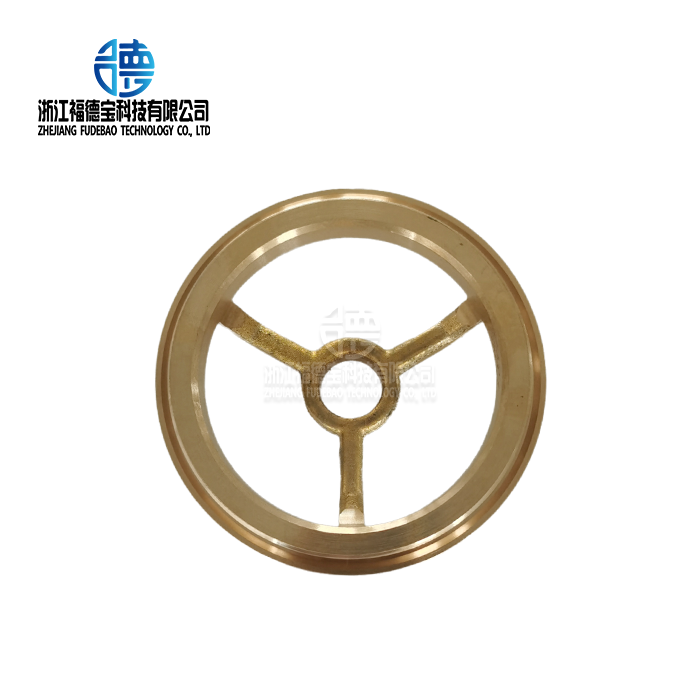

Industrial Copper Castings: From Design to Production

2026-01-27

As an advanced way to make things, industrial copper castings turn raw copper alloys into precisely engineered parts that are needed in today's businesses. These copper castings take advantage of the metal's great electrical conductivity, thermal qualities, and resistance to corrosion to work reliably in electrical systems, cars, and factories. Starting with ideas for designs and ending with finished goods requires careful planning, advanced manufacturing methods, and strict quality control measures that make sure every casting meets strict industrial standards.

Understanding Industrial Copper Castings: Properties and Types

As time has gone on, industrial copper casting has become an important method for making parts that need to be able to carry electricity and heat better. Modern copper alloy castings are very flexible and can be used for a wide range of things, from housings for electric motors to heat dissipation systems in green energy installations.

Fundamental Properties of Cast Copper Components

Copper is a great material for a wide range of industrial uses because of its natural properties. The material has an electrical conductivity value of up to 101% IACS (International Annealed Copper Standard), which is much better than aluminum or steel. This feature is very useful for companies that make electrical equipment that needs to send power efficiently all the time.

Pure copper has a thermal conductivity of 401 W/mK at room temperature, which is another important benefit. This property makes it possible to control heat well in a wide range of situations, from cooling systems for cars to industrial heat exchangers. The material is also used in specific situations where preventing contamination is important because it naturally kills microbes.

Common Copper Alloy Compositions

Different types of copper alloys are used in different industries to meet unique performance needs. These are the main types of alloys used in industrial casting:

- Phosphor Bronze Alloys (C90300–C90700): These have 10-12% tin and phosphorus added to them. They have great resistance to wear and are perfect for electrical contacts and bearings because they spring back.

- Aluminum Bronze Alloys (C95200–C95800): These alloys have 9–12% aluminum in them, which makes them stronger and more resistant to corrosion for naval and industrial pump uses.

- Silicon bronze alloys (C87300–C87800): These have 3–4% silicon in them and are very fluid when poured. They also have good mechanical qualities for use in marine and architectural hardware.

These different types of alloys help engineers choose the best material for each job by balancing things like strength, conductivity, and resistance to the environment.

Casting Methods for Copper Components

The most common way to make copper castings parts is still by sand casting, especially for bigger parts or smaller production runs. This process can handle complicated shapes and gives custom applications a lot of measurement freedom. Investment casting, on the other hand, produces better surface finishes and tighter tolerances, which makes it perfect for medical and aerospace uses that need precise parts.

When you need to make parts with better mechanical properties and less porosity, low-pressure casting methods can help. This method works especially well for car uses where choosing the right material is based on how strong it needs to be and how much it weighs.

The Copper Casting Process: From Design to Production

From rough ideas about designs to finished copper parts, the process is a planned one that combines cutting edge CAD technologies with tried-and-true manufacturing methods. This complete process makes sure that the best use of the material is made while also meeting the exact measurements and high quality surface standards needed for industrial uses.

Design Optimization for Copper Casting

Copper casting works best when the design is optimized to take into account the material's unique flow and solidification properties. Before real production starts, engineers use advanced simulation software to guess how the parts will be filled, find places where defects might happen, and make the gating systems work best.

Modern CAD systems let designers use casting-specific design rules, like using the right draft angles, fillet radii, and wall thickness changes to account for copper's tendency to shrink. These things keep common flaws like hot tears, porosity, and physical changes from happening, which could hurt the performance of the part.

Pattern Making and Mold Preparation

Pattern creation is an important step where the design purpose is turned into physical tools. Copper shrinks at a rate of about 1.5 to 2.0%, so patterns for sand casting must take that into account to make sure the finished dimensions meet the requirements. CNC machining centers are used in modern pattern shops to get the accuracy needed to keep casting quality uniform.

To prepare a mold, the right sand and binder systems must be chosen so that they can survive the high pouring temperatures of copper, which can be anywhere from 1180°C to 1250°C depending on the alloy. For precision applications, resin-bonded sands offer better accuracy in size, while green sand systems are still common because they can be recycled and are cost-effective.

Melting and Pouring Operations

To keep the metal from oxidizing and to make sure it melts properly, the atmosphere must be carefully controlled and the temperature must be carefully managed. Induction furnaces allow exact temperature control and protection from the environment, which makes it possible to maintain the quality of the melt throughout production runs.

To keep turbulence to a minimum and oxide inclusions from happening, the pouring process needs skilled management of flow rates and filling steps. To get the best casting quality, experienced foundry workers change the filling methods based on the shape of the part, the thickness of the walls, and the properties of the alloy.

Quality Control and Inspection

A lot of quality control checks make sure that every casting meets the standards before it is shipped. Ultrasonic screening and x-ray examination are examples of non-destructive testing methods that can find problems inside a part without damaging it. Using coordinate measuring tools to check the dimensions makes sure that the geometry is correct within certain limits.

Chemical research confirms the composition of the alloy, and mechanical testing confirms its strength and flexibility. These quality measures give the paperwork needed for the PPAP requirements for cars and the certification steps for aerospace.

Comparing Copper Castings with Alternative Materials

What materials are used has a big effect on how well, how much, and how complicated it is to make a component. Making wise purchasing choices that strike a balance between technical needs and financial constraints is made possible by knowing the advantages and disadvantages of copper castings and other materials.

Performance Comparison with Common Alternatives

Copper castings are better at conducting electricity than metal, steel, or plastic alternatives in situations where that is needed. Aluminum is lighter than copper, but copper is more electrically conductive (101% IACS vs. 61% IACS for aluminum). This means that copper is necessary for high-performance electrical uses.

Bronze alloys are better at resisting wear than pure copper, which means they can be used in bearing situations where steel would need extra greasing systems. Some bronze compositions are self-lubricating, which means they don't need as much maintenance and last longer in mechanical uses.

Another area where copper alloys are better than steel options is their resistance to corrosion. Copper is naturally resistant to corrosion by saltwater and many industrial chemicals, which makes it useful in marine settings and chemical processing.

Cost Considerations and Value Analysis

Copper materials are more expensive than steel or metal ones, but in some situations, the total cost of ownership is better for copper. Over the component's operational lifetime, lower maintenance needs, longer service life, and better performance characteristics can more than cover the original cost of the materials.

Material choices are also affected by how energy efficient they are. Copper is a better conductor of electricity than other metals. This means that electrical systems lose less energy, which could save a lot of money in heavy-duty uses like industrial motors and power distribution equipment.

Procurement Insights: How to Source Copper Castings?

To successfully buy copper castings, you need to know about the skills of the suppliers, their quality systems, and how the market works, which affects prices and availability. Strategic methods to sourcing can help you save money while also making sure that your supply chain works reliably.

Evaluating Supplier Capabilities

A full review of a supplier includes checking their technical skills, quality certifications, and output capacity. Suppliers should show that they know how to work with copper alloys, have the right casting tools, and have quality control systems that meet standards like ISO 9001 or TS 16949 for car use.

An evaluation of production capacity includes knowing what the equipment can do, how long the usual lead time is, and how flexible the company is to make changes to the design or the volume. Suppliers who can do both assembly and cutting can add value by reducing the amount of work that needs to be done and improving the accuracy of measurements.

Managing Lead Times and Order Quantities

Copper casting wait times depend on how complicated the part is, how many tools are needed, and how much is being made. It could take between 4 and 6 weeks for standard parts, but 12 to 16 weeks for unique designs that need new tools. Knowing these dates helps with planning production and keeping track of supplies.

Minimum order amounts are often based on how much it costs to set up and move the goods. Most of the time, suppliers prefer bigger batches so that the furnace can be used more efficiently and costs per unit are lower. However, manufacturers who are flexible can handle smaller quantities for prototypes or low-volume orders.

Fudebao Technology: Advanced Copper Casting Solutions

Zhejiang Fudebao Technology Co., Ltd. is a leader in precision metal casting. They offer full solutions that include helping with the design process from the start to providing finished parts. Our unified method combines advanced casting technologies with precise machining skills to meet the exact needs of applications in aircraft, industrial equipment, and cars.

Comprehensive Manufacturing Capabilities

Our modern factory has everything needed to make something. It has high-speed machining centers, CNC lathes, and specialized casting tools like low-pressure casting machines and die casting systems. We can keep a tight grip on quality throughout the whole production process thanks to this integrated approach. We can achieve dimensional tolerances of ±0.05mm, which is very close to what is needed for precision parts in cars and medical equipment.

Customers can easily get everything they need from raw materials to finished parts at this plant, which can melt, cast, finish, and treat the surface. Because we know a lot about copper alloy casting, we can choose the best materials and set the right processing settings for each job.

Quality Assurance and Certification

Our dedication to quality goes beyond normal manufacturing methods and includes thorough processes for testing and recording. High-tech testing tools and strict quality control procedures make sure that the quality of each component always meets international standards and customer requirements.

From making prototypes to mass production, our experienced engineering team works closely with customers to make ideas as easy to make as possible while still meeting performance standards. International brands like ESS energy storage systems and HAAS automation machine tools have praised this consultative method.

Conclusion

For modern industrial uses, industrial copper castings are advanced manufacturing process that blends metalworking knowledge with precise manufacturing methods to create parts that are needed. Copper alloys are essential for electrical equipment, automotive systems, and industrial machinery because they have special qualities like better electrical conductivity, the ability to handle heat, and resistance to corrosion. For successful procurement, you need to know about the properties of the materials, how they are made, and what the suppliers can do so you can get the best performance from your parts while keeping prices low.

FAQ

What advantages do copper castings offer over aluminum alternatives?

Copper castings provide significantly higher electrical conductivity (101% IACS versus 61% IACS for aluminum), superior thermal conductivity, and enhanced corrosion resistance. While aluminum offers weight advantages, copper's performance characteristics make it essential for high-efficiency electrical applications and demanding thermal management requirements.

How do lead times vary for custom copper casting projects?

Custom copper casting lead times typically range from 8-16 weeks depending on complexity and tooling requirements. Simple modifications to existing designs may require 6-8 weeks, while completely new components with custom tooling can extend to 12-16 weeks. Prototype quantities often receive expedited processing to support development schedules.

Can copper alloy compositions be tailored for specific applications?

Yes, copper alloy compositions can be customized to optimize properties for specific applications. Common modifications include adjusting tin content in bronze alloys for enhanced wear resistance, or incorporating aluminum for improved strength and corrosion resistance. Experienced foundries can recommend optimal alloy selections based on application requirements.

What quality certifications are important when sourcing copper castings?

Key certifications include ISO 9001 for quality management systems, TS 16949 for automotive applications, and AS9100 for aerospace components. Additional considerations include material certifications, dimensional inspection reports, and mechanical property verification documentation required for critical applications.

Partner with Fudebao Technology for Superior Copper Casting Solutions

Discover how Fudebao Technology's advanced copper casting capabilities can enhance your next project's success. Our experienced engineering team specializes in developing custom copper alloy solutions that meet demanding industrial requirements while optimizing manufacturing efficiency. Whether you need precision electrical components, thermal management systems, or specialized industrial hardware, our integrated casting and machining capabilities deliver exceptional quality with competitive lead times. Connect with our copper castings manufacturer team today at hank.shen@fdbcasting.com to discuss your specific requirements and receive detailed technical recommendations tailored to your application needs.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

American Foundry Society. "Copper Base Alloys Foundry Practice." AFS Publications, 2018.

Beeley, Peter R. "Foundry Technology." Newnes-Butterworths, 2001.

Davis, Joseph R. "Copper and Copper Alloys: ASM Specialty Handbook." ASM International, 2001.

Flemings, Merton C. "Solidification Processing in Metal Casting." McGraw-Hill, 1974.

Ravi, B. "Casting Simulation and Optimization: Benefits, Bottlenecks and Best Practices." Indian Foundry Journal, 2008.

_1756346205762.webp)

_1756352625880.webp)

_1756360265131.webp)

_1756361494985.webp)