sliding block copper castings

texture:copper

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:copper castings

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

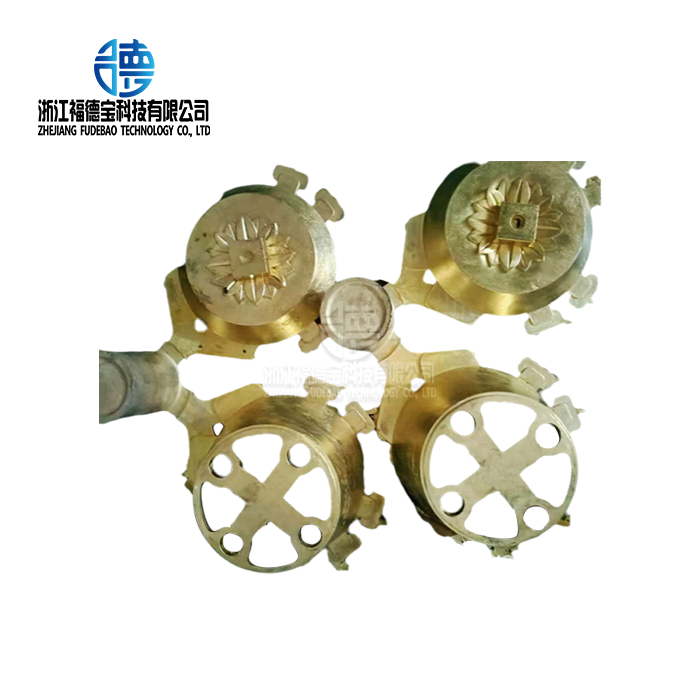

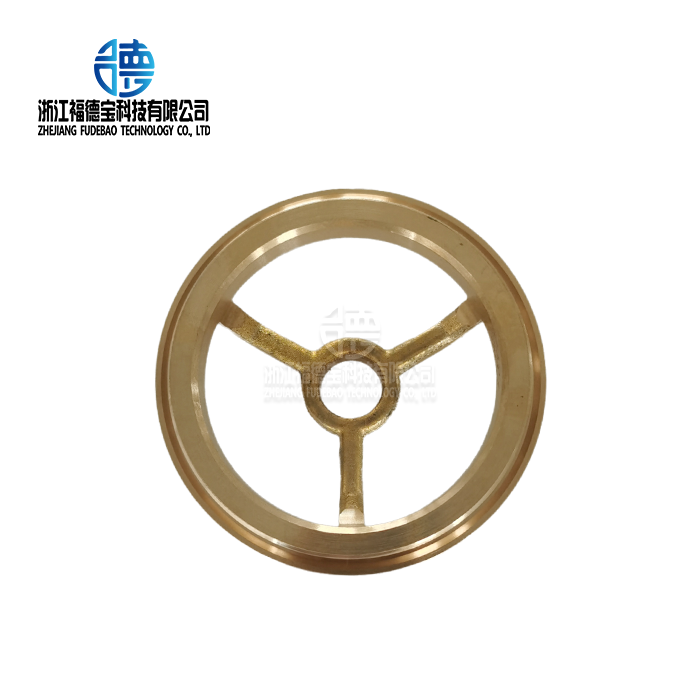

Sliding Block Copper Castings: Precision-Engineered for Industrial Excellence

Zhejiang Fudebao Technology Co., Ltd. is your trusted manufacturer and supplier of high-quality sliding block copper castings. With 24 a long time of skill in exactness casting, we provide predominant items that meet the requesting needs of different businesses. Our products offer uncommon wear resistance, warm conductivity, and disintegration resistance, making them idealize for essential applications in overpowering device, car, and mechanical adapt sections.

Product Description

Our products are built to work best in places where there is a lot of stress. The sizes of these parts are very exact, they have a great finish on the outside, and they work very well. Expert casting techniques and top-notch copper materials are what we use to make sure that your uses will last and work well.

Parameters

| Property | Specification |

|---|---|

| Material | C83600 (or custom alloy) |

| Tensile Strength | ≥ 240 MPa |

| Elongation | ≥ 20% |

| Hardness | 65-95 HB |

| Surface Finish | Ra ≤ 3.2 μm |

| Dimensional Tolerance | ±0.1 mm |

| Weight Range | 0.5 - 50 kg |

Product details pictures

Applications

- Linear motion systems in industrial machinery

- Automotive suspension components

- Hydraulic and pneumatic cylinders

- Bearing housings in heavy equipment

- Guide rails for elevators and lifts

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, is a leading provider of precision metal castings. Our state-of-the-art 3000㎡ facility in Zhuji, Zhejiang Province, boasts advanced equipment and a comprehensive production system. We specialize in aluminum combination, copper combination, and stainless steel castings, serving around the world markets in car, mechanical equip, and essentialness divisions. Our commitment to headway and quality has made us a favored assistant for customized mechanical metal parts.

Why Choose Us?

- 24 years of specialized casting experience

- Advanced manufacturing capabilities with ±0.05mm accuracy

- Comprehensive quality management system

- Flexible production for both small and large orders

- Expert technical support and customization options

Production Process

- Material selection and preparation

- Mold design and fabrication

- Melting and pouring

- Heat treatment (if required)

- Machining and finishing

- Quality inspection and testing

- Packaging and shipping

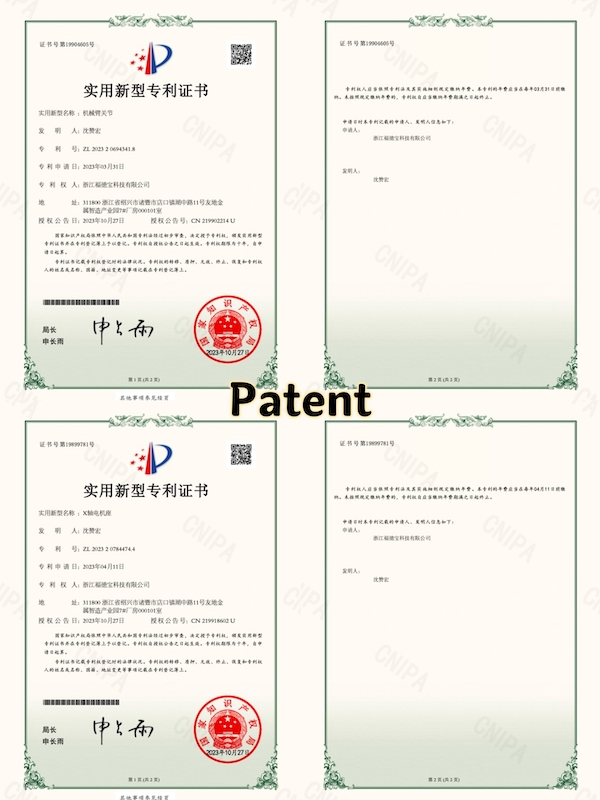

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- CE Marking for European market compliance

- RoHS and REACH environmental standards

Packaging and Shipping

We ensure safe transportation of your sliding block copper castings with:

- Custom-designed protective packaging

- Corrosion-inhibiting wrapping for long-term storage

- Secure palletization for bulk orders

- Flexible shipping options (air, sea, or land freight)

FAQ

Q1: What is the minimum order quantity for the products?

A1: Our minimum order quantity is 50 pieces, but we offer flexibility for sample orders and prototyping.

Q2: Can you provide custom alloy compositions for specific applications?

A2: Yes, we can tailor alloy compositions to meet your specific requirements for strength, conductivity, or corrosion resistance.

Q3: What is the typical lead time for a standard order?

A3: Standard lead times range from 3-4 weeks, depending on order size and complexity. We also offer expedited services for urgent needs.

Q4: Do you provide material certifications and test reports with each order?

A4: Absolutely. We provide comprehensive material certifications and test reports to ensure full traceability and quality assurance.

Contact Us

Ready to elevate your industrial performance with our premium sliding block copper castings? Contact our expert team today for a personalized consultation and quote.

Email: hank.shen@fdbcasting.com

Experience the Fudebao difference – where precision meets reliability in every casting.

_1756361494985.webp)

_1756361323684.webp)

_1756361423150.webp)