When you buy CNC machined parts from China, you can expect to find low prices, modern production tools, and a large network of suppliers. In China, CNC machining has changed a lot in the last ten years, thanks to companies spending a lot of money on new tools and quality control methods. Precision production services from Chinese suppliers are now on par with those from Western suppliers, and they often cost a lot less. When looking for precision parts for your business, knowing the market, quality standards, and selection factors will help you make smart choices.

Understanding CNC Machining and Its Advantages

Computer Numerical Control (CNC) machining is the most important part of current precise manufacturing. Machine tools are controlled by pre-programmed software in this automatic process, which makes parts that are very accurate and can be made over and over again. The technology has changed the way we make parts, especially in fields that need very precise measurements and complicated shapes.

Advanced Equipment Capabilities in Chinese Facilities

In the past few years, Chinese factories have put a lot of money into buying cutting-edge tools. Most reliable providers use 3-axis to 5-axis CNC tools that can work with a wide range of materials, such as engineering plastics, aluminum alloys, stainless steel, and brass. Tolerances of as little as ±0.01 mm can be reached by these tools, which meets the strict needs of aerospace and automotive uses. When CAD and CAM software tools work together, it's easy to go from design ideas to finished goods.

Material Versatility and Processing Excellence

Modern CNC factories in China are great at handling different kinds of materials for CNC machining to meet the needs of different industries. The great strength-to-weight ratio of aluminum metals makes them famous for use in cars and spacecraft. Copper alloys are used in the power and energy sectors, while stainless steel parts are used in the medical device and food processing businesses. Being able to work with different materials under one roof makes the buying process easier for people who want to buy more than one type of component.

Precision Manufacturing Benefits

Because CNC methods are uniform, the results are the same from one production run to the next. Computer-controlled systems are better than hand machining because they don't depend on human mistake and keep measurements accurate over long production runs. This dependability is very important in fields like making cars, where consistent parts have a direct effect on how well the assembly line works and how well the final product is made.

Key Considerations When Importing CNC Machined Parts from China

To import goods successfully, you need to carefully consider a number of factors that affect both the quality of the goods and the total cost of ownership. Knowing about these things helps buying teams make smart choices that meet their business needs and stay within their budgets.

Technical Capability Assessment

There is more to judging a supplier's professional skills than just looking at their list of tools. How complicated the parts they can make depend on how advanced their machines are, ranging from simple 3-axis mills to advanced 5-axis centers. Specialization in an industry is very important. For example, suppliers that focus on car parts know what PPAP paperwork standards are, and facilities that focus on aircraft keep their AS9100 certifications. By looking at their collection of finished projects, you can get an idea of how much experience they have with similar apps.

Capacity for production and the ability to grow are important factors for long-term relationships. Suppliers need to show that they can handle everything from making prototypes to mass production without lowering quality standards. This kind of adaptability is very important when market needs change or when product lines grow.

Cost Structure Analysis

When it comes to price, Chinese CNC machining usually beats out other options, especially for large orders. Different things affect how much things cost:

The following factors have a big effect on the total cost of the job and should be carefully thought through when choosing a supplier:

- Costs and supply of materials – The prices of raw materials change based on the state of the global market. In recent years, the prices of aluminum and steel have been especially volatile.

- Complexity and time to machine – Complex shapes that need 5-axis processing demand faster speeds than simple 3-axis processes.

- Order number and batch sizes: When you buy more, you save money because of economies of scale.

- Finishing and secondary operations: Heat treatment, surface processes, and assembly services add value but raise the overall project cost.

Because these cost factors affect each other in many complicated ways, it is important to do a full analysis in order to make accurate budget plans and compare suppliers.

Logistics and Communication Planning

Lead times usually run from one to four weeks, but they depend on how complicated the part is and how big the order is. Faster processing can be used to meet urgent requests, but there is normally an extra fee. Shipping plans and customs clearance processes need to be planned ahead of time to avoid delays that could throw off production schedules.

Structured project management methods are needed for communication to work well across time zones. Clear documentation standards, regular reports on progress, and quick responses from expert support help keep the project moving forward and deal with problems quickly.

Managing Risks and Ensuring Quality

Ensuring quality is the most important part of doing business with other countries. Setting up complete quality control systems guards against problems that might happen and increases trust in the supplier's abilities.

Quality Control Protocols

Clear recording of specifications is the first step in putting in place strong quality control measures. Lack of clarity in technical designs, material requirements, and testing criteria can cause parts that don't meet standards. Before full production starts, sample part review steps make sure that the supplier understands.

Independent checks of quality standards for CNC machining are done by third-party testing services. These checks can happen at different times, such as when the materials are first received, while they are being made, and again before they are shipped. Keeping records of inspection results makes quality records that can be tracked and helps with efforts to keep improving.

Certification and Compliance Requirements

Industry-specific certificates show that a provider is committed to meeting quality standards. ISO 9001 certification means that a basic quality management system has been put in place, while AS9100 approval covers the needs of the aerospace business. To make sure they meet quality standards for the car industry, suppliers should keep their IATF 16949 license.

When sharing private ideas, you need to be very careful about protecting intellectual property. Clear ownership documents, non-disclosure agreements, and selective information sharing all help protect important intellectual property while allowing people to work together effectively.

How to Choose the Right CNC Machining Partner in China?

To find the best CNC machining partner for your needs, you need to carefully consider a number of factors that are relevant to your business and operational goals.

Industry Experience and Specialization

Suppliers who have worked in your business before know the specific needs and problems that come up in your field. Suppliers to the automotive industry know how important it is to have accurate measurements and PPAP paperwork, and partners in the aircraft industry know how important it is to be able to track products and get certifications. With this specialized information, the job will go more smoothly and there will be fewer quality problems.

As part of a technical capability review, both the complexity of the tools and the engineering support skills should be looked at. In addition to basic production services, advanced facilities offer design optimization advice, manufacturability analysis, and cost reduction advice that are very useful.

Value-Added Services and Support

Leading providers set themselves apart in CNC machining by providing a wide range of services that go beyond simple cutting. Offering surface finishing, assembly, and custom packing makes managing the supply chain easier and the job less complicated overall. Most of the time, these bundled services are more cost-effective than managing different providers individually.

The level of after-sales help has a big effect on how well a partnership does in the long run. Quick technical help, warranty coverage, and the ability to fix problems make sure that cooperation goes smoothly over time. When suppliers put money into customer relationship management, it shows that they want to build long-term partnerships.

About Fudebao Technology

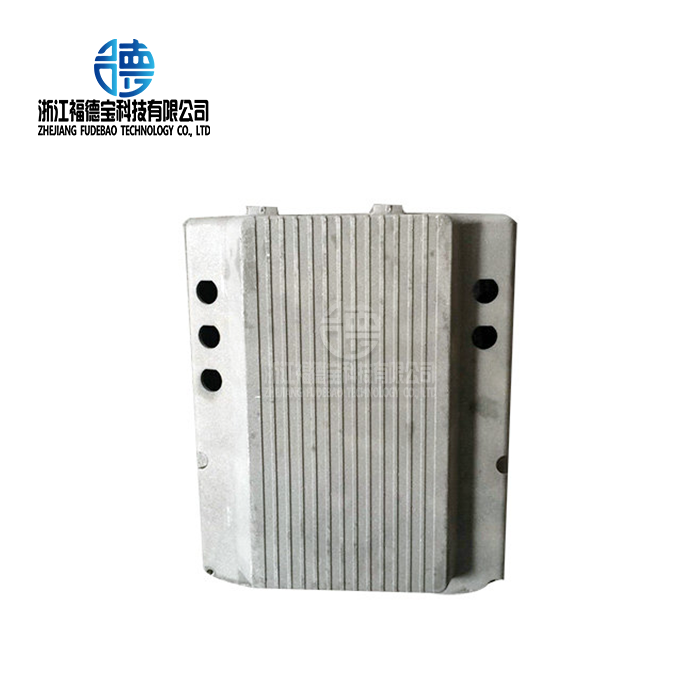

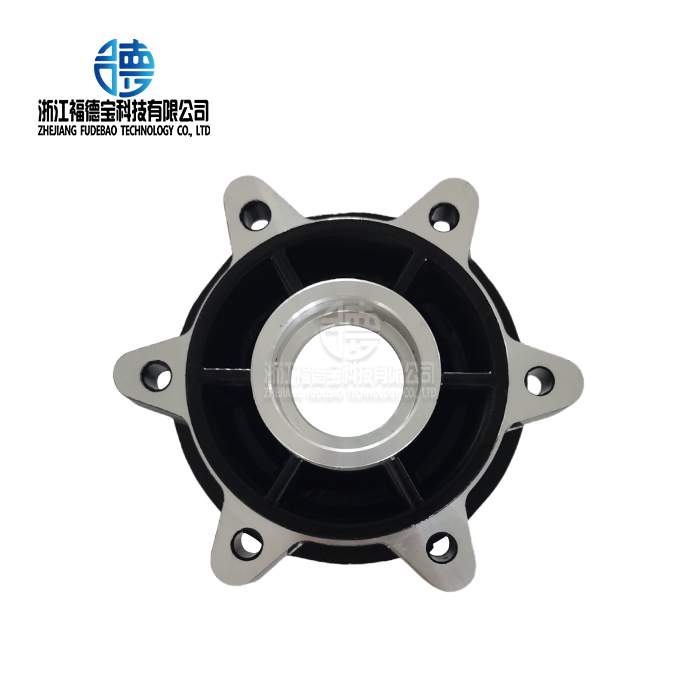

Zhejiang Fudebao Technology Co., Ltd. has become a top company for precise production, specializing in casting and milling solutions for aluminum alloys, copper alloys, and stainless steel. Our wide range of skills helps the aerospace, industrial equipment, machinery production, and car industries around the world with high quality and dependability.

Advanced Manufacturing Capabilities

The most up-to-date machines in our building are high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting equipment. With this full setup, we can handle the whole manufacturing process, from melting the metal to casting it, then precision milling it, and finally treating the surface. Our combined method makes sure that quality control is at its best at every stage of production.

We keep precise tolerances of up to ±0.05mm, which lets us meet the exact needs of aircraft uses, medical device housings, and precision car parts. Our quality control tools help with everything from making prototypes to making a lot of them.

Global Partnership Excellence

As an intermediary, we've worked with and had direct supply relationships with well-known foreign names, such as American HAAS automatic machine tools and ESS energy storage systems. That wide range of knowledge has made us a leading metal foundry company in China's industrial scene.

Our foreign clients can get everything they need from raw casting blanks to finished goods all in one place. This makes the buying process easier for them. Our dedication to quick response to customer needs and top-notch technical proficiency makes it possible for people from different time zones and cultures to work together effectively.

Conclusion

When done carefully, importing CNC-machined parts for CNC machining from China can save you a lot of money, make the quality better, and make the supply chain work better. Picking the right suppliers, managing quality well, and having clear communication rules are all important for success. China's manufacturing scene has grown up a lot, and now the biggest providers can match or beat the powers of standard alternatives. Procurement teams can build relationships that work well and bring long-term benefits by focusing on technical skills, knowledge in the field, and services that add value. Knowing the whole process, from the first review to ongoing relationship management, helps you make smart decisions and finish projects successfully.

FAQs

How long do most CNC made parts from China take to get to me?

The length of time it takes to get a part depends on how complicated it is, how many you order, and how busy production is at the moment. Most simple parts made from standard materials can be finished in one to two weeks. More complicated parts that need 5-axis machining or special materials, on the other hand, may take three to four weeks. People who need things quickly can get them processed faster, but they usually have to pay more for this service.

How can I make sure that the quality of the CNC parts I buy is always the same?

For quality to be consistent, there needs to be a lot of written information, like precise technical drawings, material specs, and inspection criteria. Before production starts, sample part review steps make sure that the supplier understands. Clear quality control procedures, third-party checks, and supplier audits help keep standards high throughout the relationship. Setting up regular ways to talk makes sure that problems are solved quickly.

What kinds of materials are popular in China for CNC machining?

Most of the time, Chinese CNC shops work with combinations of aluminum, carbon steel, brass, copper alloys, and industrial plastics like PEEK, nylon, and Delrin. Material supply varies by provider, and bigger sites tend to have a wider range of items in stock. For odd material needs, it's best to plan ahead as early as possible because some materials may have longer lead times or minimum order amounts.

Partner with Fudebao Technology for Your Precision Manufacturing Needs

Picking the right CNC machining provider can make it easier to develop new products and make more of them. Fudebao Technology mixes advanced production skills with quick customer service to give you precision parts that are made exactly the way you want them. Our extensive buildings and skilled engineering staff offer full solutions from the initial design advice to the final delivery. We know the specific needs of uses in the automobile, aerospace, industrial, and electrical fields and make sure that your parts meet the standards of those fields. Email us at hank.shen@fdbcasting.com to talk about the details of your project and get a quote from our CNC machining maker team.

References

Manufacturing Engineering Society. "Global CNC Machining Market Analysis and Industry Standards." Industrial Manufacturing Quarterly, 2023.

International Trade Commission. "Precision Manufacturing Supply Chain Study: Asia-Pacific Region." Government Publishing Office, 2023.

American Society of Mechanical Engineers. "Quality Standards for Imported Precision Components." ASME Press, 2022.

Automotive Industry Action Group. "Supplier Selection Guidelines for Global Sourcing." AIAG Publications, 2023.

National Institute of Standards and Technology. "CNC Machining Tolerance Standards and Best Practices." NIST Special Publication, 2022.

Supply Chain Management Review. "Risk Management in International Manufacturing Partnerships." Peerless Media, 2023.

_1756344684491.webp)

_1756348780785.webp)