CNC machining is the most important part of modern precise manufacturing. It turns raw materials into important parts used in almost every business. This computer-controlled subtractive manufacturing method carefully takes away material from workpieces to make parts that meet the strict requirements of medical, military, automobile, and industrial uses. Because the technology can produce consistent results while keeping tight limits, it is essential for B2B buying workers looking for reliable manufacturing solutions that can be used for everything from testing to mass production.

Understanding CNC Machining and Its Role Across Industries

Computer Numerical Control (CNC) making has changed the way that businesses make accurate parts. This automatic process makes sure that the parts are always of high quality and meet the strict requirements of many industries, from car housings to aircraft structural elements.

What is CNC Machining? Definition and Basic Concepts?

Computer Numerical Control technology uses software that has already been designed to control how workplace tools and machines move. The process starts with G-code directions being turned into a computer design file, which is usually made with Computer-Aided Design software. These directions tell cutting tools exactly where to go to take material from workpieces. This makes it possible to make parts with exact measurements that can't be achieved by hand.

The main benefit is that CNC machines can make the same parts over and over again once they are set to do so. This makes them perfect for both making prototypes and large-scale production runs. This level of uniformity is very important in fields like making cars, where every part has to meet exact standards for safety and performance.

Overview of CNC Machining Processes and Materials Used

Today's precision manufacturing includes a number of different methods, each of which is best for a certain job. Milling removes material from fixed workpieces using spinning cutting tools. This is a great way to make surfaces with complex shapes and patterns. When you turn something, you turn it against cutting tools that stay in one place. This is best for making circular parts like shafts and bearings.

Another great thing about this way of making things is that it can be used with a lot of different materials. Aluminum alloys are famous in the aircraft and car industries because they are strong for their weight. Copper metals are better at conducting electricity than stainless steel, which makes them ideal for use in the energy sector. Stainless steel is resistant to rust and is used in medical and food-grade components. Advanced industrial plastics and alloys make it easier to make parts that are light and don't react with chemicals.

Key Benefits Driving CNC Adoption in Industrial Settings

Automated cutting is widely used because it has a number of strong benefits that directly solve problems in modern industry. Precision is very important. Modern tools can often get margins of less than 0.05 mm, which meets the demanding needs of fields like aircraft engineering and medical device making.

Gains in production speed for CNC machining are also very important. Once they are set up, machines run constantly with little to no control, which greatly reduces the cost of labor while raising output. This technology also gets rid of human mistake, so the standard is the same throughout the whole production run. Because the technology is so adaptable, makers can quickly switch between different part designs. This works for both custom development and mixed-production situations.

Typical Tolerances and Quality Standards in CNC Machining

Different businesses have very different quality standards for precise manufacturing, which is because each has its own working needs and safety concerns. To make sure that engine units and transmission systems work right, automotive parts usually need margins of ±0.1mm to ±0.05mm. Even stricter requirements are needed for aerospace uses, where important structure parts often need to be within ±0.025mm of the exact size.

Making medical devices requires even higher levels of accuracy. For example, some parts of implants need to be able to hold limits of as little as ±0.01mm. Because of these strict requirements, production must use high-tech checking tools and strict quality control methods. Surface finish needs are also different. For some uses, finishes need to be as smooth as mirrors, while for others, the right amount of roughness is important for lubricating or gluing.

Major CNC Machining Applications Across Key Industries

Precision production technology can be used in a lot of different industries because it is so flexible. Each industry uses its own set of skills to meet its own set of practical needs. For example, the aircraft industry needs to find ways to make their products lighter while still maintaining their sturdiness.

Automotive Industry – Precision Parts and Prototyping

Computer-controlled cutting is a big part of both making production parts and developing prototypes for the auto industry. To make sure they fit together correctly and last a long time, engine blocks, transmission housings, and chassis parts need to be precisely measured. It is perfect for making hydraulic valve bodies and fuel injection parts because it is so good at making complex internal shapes.

Rapid cutting is needed to test new ideas quickly during prototype creation in car design. Multiple design versions can be tested quickly and efficiently by engineering teams, which cuts down on development time and improves the quality of the end product. Being able to machine production-grade materials during development makes sure that test results properly show how the final part will work.

Aerospace Sector – Complex and High-Precision Components

Advanced cutting methods are needed because aerospace uses need the highest levels of accuracy and material performance. Structures, engines, and electronics housings for airplanes have to stay strong and reliable while also meeting strict weight standards. Titanium and aluminum metals that are often used in aircraft profit from the ability to precisely remove material while keeping the structure's integrity.

The need for verification in aircraft manufacturing is a great match for automatic cutting. With thorough records of tools, materials, and process factors, you can follow each part through the whole production process. This paperwork is necessary for getting certified and for ongoing quality control programs.

Medical and Healthcare – Customized Implants and Surgical Tools

Making medical devices is one of the most difficult tasks that requires fine machine technology. For orthopedic implants to fit and work right in the body, they need to be made from safe materials that are cut to exact specs. For device absorption and long-term success, it's important to be able to make surfaces with complicated curves and exact shapes.

The production of surgical instruments benefits from computerized processes like CNC machining because they ensure uniform quality and keep the sharp edges. Custom tools for specific processes can be made quickly, which helps medical methods get better and treatments are tailored to each patient. Medical uses need to be sterile, which is similar to how clean and accurate modern machining is.

Electronics and Telecommunications – High-Precision Components

Precision cutting is a good way to deal with the unique manufacturing problems that come up because the electronics industry is always getting smaller. Tight precision and great surface finishes are needed for connector housings, heat sinks, and electromagnetic protection parts. For high-performance electronics, being able to make complex cooling pathways into heat absorption parts is a must.

For signal purity and long-term dependability, telecommunications equipment depends on parts that are carefully made. Antenna parts, waveguide sections, and attachment tools must stay the same size even when the surroundings changes. Precision cutting makes sure that the dimensions stay the same, so the product works the same way in all weather and humidity conditions.

Industrial and Energy – Heavy-duty Parts and Tooling

Applications in industrial gear and the energy field need strong parts that can handle harsh working conditions. To keep damage to a minimum and performance at its peak, pump housings, compressor parts, and motor parts must fit perfectly. For making industrial tools, it's important to be able to make big, heavy parts accurately.

It is becoming more and more important for wind turbine units, solar tracking systems, and energy storage tools to have precision-machined parts. These parts have to work reliably in harsh environments and stay in the right place so that the energy gathering and exchange process works as efficiently as possible.

Choosing the Right CNC Machining Methods for Your Industry Needs

Choosing the right manufacturing methods requires giving careful thought to the needs of the part, the qualities of the material, and the amount that will be made. After learning about the pros and cons of various methods, buying workers can make smart choices that improve both performance and cost.

Types of CNC Machines and Their Specific Industrial Applications

Vertical machining machines are great for making complicated parts with many features, like frames for cars and housings for electronics. These machines make it easy to change tools and add parts, which helps keep production running smoothly. Horizontal machining centers are better at getting rid of chips and can handle bigger workpieces, so they can be used to make industrial pump housings and big aircraft parts.

Multi-axis cutting makes it possible to make very complicated shapes in just one setup, which cuts down on handling time and improves accuracy. When accurate cutting is needed on complex curvy surfaces, like on aircraft parts and medical implants, five-axis tools are a must. Swiss-type lathes are great for making small, precise parts for medical and electronics uses because they can control the dimensions of parts with large length-to-diameter ratios very well.

Material Selection: Metals, Plastics, and Composites for CNC Machining

Choosing the right material for CNC machining has a big effect on both the cutting process and the performance of the finished part. Aluminum alloys are popular for use in cars and spacecraft because they are easy to machine and have a good strength-to-weight ratio. Different types of aluminum have different qualities. For example, 6061 is a good all-around aluminum, while 7075 is stronger and better for tough jobs.

Stainless steel types are used in medical and food-grade settings where resistance to rust is important. Grade 316 is better at resisting rust in sea and chemical conditions, while 17-4 PH is stronger and better for use in aircraft. Titanium metals are very strong and biocompatible, but they are hard to make. They are used in medical implants and aircraft parts.

Precision and Tolerance Requirements Across Different Sectors

Tolerance standards help buying workers choose the right manufacturing methods and keep parts from being over-engineered. For automotive uses, practical standards make sure that the parts fit together and work right without having to meet too many strict requirements, which drives up costs. Critical wear areas might need tighter limits than features that don't do anything.

Because of safety and efficiency needs, aerospace parts often need the tightest specifications. For best performance, structural elements must keep their precise fits even when the load changes, and moving parts must be carefully controlled for clearance. Medical uses have to balance the need for precision with the need to keep costs low. They do this by putting tight limits on useful features that are very important and loosening them on areas that aren't as important.

CNC Machining vs Other Manufacturing Methods

Comparing different ways of making things helps find the most cost-effective way to do something for a certain use. Traditional casting methods are great for making a lot of complicated forms, but they might need extra work to get certain features just right. Investment casting can get very accurate measurements, but it might be too expensive for small quantities or design changes that happen often.

Additive manufacturing lets you build parts with complicated inside shapes, but it usually can't get the top finishing and exact measurements that precise cutting can. For some uses, hybrid methods that combine additive manufacturing for complicated forms with finish cutting for important surfaces could be very useful. Which one to use relies on how much is being made, how complicated the plan is, and how precise the work needs to be.

Streamlining Procurement: How to Source Reliable CNC Machining Services?

To successfully buy machining services, you need to know what the suppliers can do, how they handle quality, and how they make things. To have good relationships with suppliers, you need to be able to clearly explain what you need and set reasonable goals for both quality and service.

Assessing CNC Machining Suppliers: What to Look for

Quality badges tell you a lot about a supplier's skills and how committed they are to managing quality in a structured way. An ISO 9001 certification shows that you know basic quality management practices. Certifications specific to your industry, like AS9100 for aerospace or ISO 13485 for medical devices, show that you know more about meeting specific needs.

An evaluation of production skills for CNC machining should look at how well the equipment is being used, how sophisticated it is, and what backup plans are in place for important equipment. Suppliers who have up-to-date tools and regular repair plans show that they are dedicated to consistently meeting quality and delivery goals. Quality control tools, such as inspection gear and statistical process control systems, show that the ability to keep dimensions consistently accurate is present.

Cost Factors and Quoting Process for Custom CNC Machining

Understanding what causes costs makes it easier to negotiate purchases and improve designs. The prices of materials change a lot depending on the metal and the market factors at the time. Compared to easier designs, cutting takes a lot longer and costs a lot more when the geometry is complicated and needs multiple sets or special tools.

When you think about volume, setup costs and possible tooling inputs have a big effect on unit prices. Suppliers may give better prices for bigger orders or deals to supply for a long time. Lead times also affect prices, and because of the extra work that goes into scheduling and paying workers overtime, faster delivery usually costs more.

Working with Contract Manufacturers and Managing Bulk Orders

When working with a contract manufacturer, it's important to be clear about quality standards, delivery goals, and performance measures. Setting up quality agreements that spell out review requirements, paperwork needs, and corrective action steps helps keep everyone on the same page and ensures consistent performance.

Controlling the data process and reviewing success on a daily basis are helpful for managing large orders. Suppliers should show that they can meet measurement standards throughout production runs by showing process capability studies. Regular quality checks and tracking of performance data help keep suppliers accountable and find ways to make things better.

Rapid Prototyping and Low Volume CNC Machining – When and Why

Rapid prototyping services make it possible to test and confirm designs quickly, which shortens the time it takes to make a product. These days, machine shops can quickly make sample parts, usually just a few days after getting the design files. This speed is necessary for competitive product creation processes, where shorter times to market lead straight to more money for the business.

Low-volume production runs are a step between development and full-scale production. They let you test the market and make design changes before you spend a lot of money in full-scale production. This method lowers the risk while giving real-world performance data that helps with final design choices and improving the manufacturing process.

Company Introduction and Our CNC Machining Solutions

Zhejiang Fudebao Technology is the best at making precise parts. They specialize in casting aluminum alloys, copper alloys, and stainless steel, and they can also do advanced cutting. Through direct supply agreements with top foreign names, we serve clients around the world in the automobile, industrial equipment, tool production, and aircraft industries.

Overview of Our Capabilities and Industry Experience

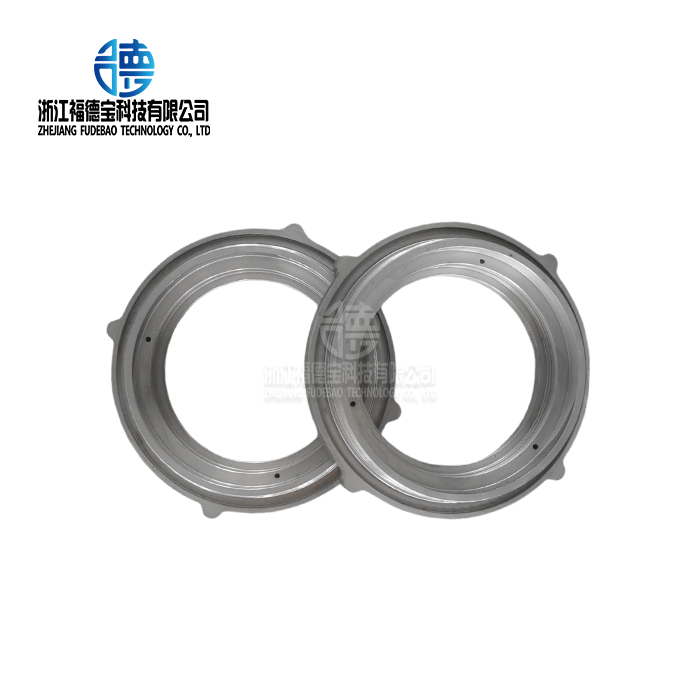

There is state-of-the-art machinery for CNC machining in our building, such as high-speed machining centers, precision CNC lathes, low-pressure casting tools, and die casting equipment. This all-in-one setup lets the whole "melting-casting-finishing-surface treatment" process happen under one roof. This makes sure that quality control and delivery efficiency are maintained from raw materials to final parts.

Precision parts for cars, housings for industrial equipment, and parts for spacecraft are all things that the company has experience with, and they have proven they can keep their measurements within ±0.05mm. Our long-term partnerships with American companies that make HAAS automation machine tools and ESS energy storage batteries show that we are dedicated to meeting the needs of challenging foreign markets with consistent quality and dependability.

Custom CNC Machining Services Tailored to Industry Needs

Our wide range of machining services meet the needs of a wide range of industries by using adaptable production methods. Our automotive clients benefit from our experience in precision finishing and aluminum die-casting, which lets us make parts that meet strict standards for size and longevity. We use our knowledge of how to machine stainless steel and quality systems that are set up to meet legal requirements to make medical equipment housings.

Our heavy-duty machining skills are used to make pump housings, compressor parts, and gearbox elements for industrial equipment. When we use our low-pressure casting methods along with finish cutting, the parts we make have great mechanical qualities and are the right size. Surface treatment options make sure that parts meet standards for both functionality and appearance in all settings.

Customer-Centric Approach: From Quote to Delivery

Our fast pricing process starts with a careful study of the design and an assessment of how well it can be manufactured. This makes sure that the best production methods are used and that delivery dates are realistic. Design advice services help make sure that parts are made as efficiently as possible while still meeting their useful needs. The advice on choosing materials takes into account both the performance needs and the chances to save money.

Production planning combines the shipping needs of the customer with effective organizing methods that keep quality standards high throughout all activities. Quality paperwork packages include full inspection records and tracking information to help customers meet quality standards and government rules. Support after delivery includes expert help and design changes to meet changing application needs.

Why Partner with Us for Your CNC Machining Projects?

When you choose Fudebao Technology, you get access to a wide range of manufacturing options backed by excellent customer service and organized quality management. Our combined method gets rid of the need for complicated planning and makes sure that quality is the same at every stage of output. Competitive price shows that processes are running smoothly and that there are good relationships for getting materials.

Technical knowledge includes material science, improving industrial processes, and quality control, which lets people work together to solve tough problems. Our dedication to constant improvement gives you access to new production technologies and best practices that are always changing. A long-term relationship method focuses on both parties' success through reliable delivery and quick customer service.

Conclusion

The use of precision production technology like CNC machining is growing in many fields because it can make reliable, high-quality parts that meet strict operating requirements. Modern manufacturing can't do without automatic machining processes because they are so flexible and reliable. They are used to make everything from precision parts for cars to structure elements for spacecraft. Procurement workers can make the best use of this technology by knowing how to meet the needs of specific applications and what suppliers can do. This improves both the performance of parts and the speed of production. Investing in good cutting services pays off in the form of lower guarantee costs, better product performance, and a stronger place in competitive markets that demand it.

FAQs

What kinds of things can CNC technology be used to cut?

Aluminum alloys, stainless steel grades, titanium, brass, copper, industrial plastics, and advanced composites are just some of the materials that can be machined today. The choice of material is based on its power, resistance to rust, electrical conductivity, and biocompatibility. Every material has its own problems when it comes to cutting, but skilled suppliers can solve these problems by using the right tools and setting the right process conditions.

How do I pick the best CNC machining company for my job?

Check out possible providers' industry qualifications, the power of their tools, their quality control systems, and their track record with similar projects. Ask for samples of parts or case studies that show they can meet your standards for size and finish. Think about how close the provider is geographically to make contact and operations easier, and make sure they can meet your number and shipping requirements.

I need special CNC made parts. How long will it take to get them?

Lead times are very different depending on how complicated the part is, how much of it is needed, and how much of the supplier's capacity is being used at the moment. It might only take a few days to finish simple test parts, but it could take several weeks to finish complex production parts. Setting reasonable goals during the quotation process will help you keep your shipping promises throughout your supply relationship.

Can CNC machining be used for both small batches and large production runs?

Yes, current cutting technology works well for both small prototypes and large production runs. For prototype development, it's helpful to be able to set up quickly and have a lot of design options. For production runs, automation and well-tuned processes save time and money. Many companies offer both, which makes it easy to move from the research phase to the production phase while keeping quality standards and style consistency.

Get Started with Precision CNC Machining Today

Working with an experienced CNC machining provider can help you turn your manufacturing needs into precisely made parts. Fudebao Technology uses cutting edge tools and years of experience in the field to make parts that are better than expected in terms of quality and dependability. From the first planning meeting to the final delivery, we take care of everything to make sure your project is a success while also making it as efficient and cost-effective as possible. Email us at hank.shen@fdbcasting.com to talk about your unique needs and find out how our precision manufacturing services can help you reach your goals for product creation and production.

References

Smith, J.M. "Advanced Manufacturing Technologies in Automotive Industry Applications." Journal of Manufacturing Science and Engineering, Vol. 142, 2023.

Thompson, R.K. "Precision Machining Standards for Aerospace Components." International Journal of Aerospace Engineering, 2024.

Davis, L.A. "Material Selection Guidelines for CNC Machining Applications." Manufacturing Technology Review, 2023.

Wilson, P.C. "Quality Control Systems in Computer Numerical Control Manufacturing." Industrial Quality Management Quarterly, Vol. 28, 2024.

Anderson, M.E. "Cost Optimization Strategies in Modern Precision Manufacturing." Supply Chain Management Review, 2023.

Brown, S.T. "Tolerance Analysis and Design for Manufacturability in CNC Machining." Precision Engineering Journal, Vol. 45, 2024.

_1756346310015.webp)

_1756348780785.webp)