Understanding Low Pressure Casting and Its Advantages

Principles of Low Pressure Casting

Low pressure casting is an advanced metal forming technique that leverages controlled pressure to create high-quality components. This process involves the application of low pressure, typically ranging from 0.3 to 1.5 bar, to force molten metal into a mold cavity. The pressure is maintained throughout the solidification process, ensuring complete filling of the mold and minimizing defects.

One of the key aspects of low pressure casting is the bottom-gating system. Unlike traditional gravity casting methods, the molten metal is introduced from the bottom of the mold. This approach reduces turbulence and oxidation, leading to improved metal quality and reduced porosity. The controlled fill rate also allows for better management of solidification, resulting in enhanced microstructural properties.

Advantages over Traditional Casting Methods

Low pressure casting offers several advantages over conventional casting techniques. The controlled filling process results in reduced turbulence, minimizing the risk of oxide inclusion and gas entrapment. This leads to castings with improved mechanical properties and a smoother surface finish. The process also allows for the production of thin-walled components with complex geometries, expanding design possibilities for various industries.

Another significant advantage is the improved yield. Low pressure casting typically achieves a metal yield of 95% or higher, compared to 50-60% in gravity casting. This efficiency not only reduces material waste but also contributes to cost savings in production. The process also offers excellent repeatability, ensuring consistent quality across production runs.

Applications in Various Industries

The benefits of low pressure casting have led to its widespread adoption across multiple industries. In the automotive sector, it's used to produce engine blocks, cylinder heads, and wheels, where porosity control and microstructural integrity are crucial. The aerospace industry utilizes this technique for manufacturing turbine blades and structural components, taking advantage of its ability to produce complex, lightweight parts with excellent mechanical properties.

In the energy sector, low pressure casting is employed in the production of wind turbine components and solar panel frames. The medical industry also benefits from this technology, using it to create implants and surgical instruments that require high precision and consistent quality. As the demand for high-performance, lightweight materials continues to grow, the applications of low pressure casting are expected to expand further.

Impact on Porosity Reduction and Control

Mechanisms of Porosity Formation in Castings

Porosity in castings can significantly impact the mechanical properties and overall quality of the final product. Understanding the mechanisms of porosity formation is crucial for implementing effective control measures. In traditional casting methods, porosity often results from gas entrapment during mold filling, shrinkage during solidification, and dissolved gases in the molten metal.

Gas porosity occurs when atmospheric gases or those generated from mold materials become trapped in the solidifying metal. Shrinkage porosity, on the other hand, is a result of volume reduction as the metal transitions from liquid to solid state. Both types of porosity can lead to weakened structural integrity and reduced performance of the cast component.

How Low Pressure Casting Minimizes Porosity?

Low pressure casting offers several mechanisms for minimizing porosity in cast components. The controlled fill rate and bottom-gating system reduce turbulence during mold filling, significantly decreasing the risk of gas entrapment. The applied pressure during solidification helps compensate for shrinkage, forcing liquid metal into interdendritic spaces and reducing the formation of shrinkage porosity.

The process also allows for better control of metal temperature and cooling rates. This precise control enables the optimization of solidification patterns, promoting directional solidification from the extremities towards the feeding system. As a result, the formation of isolated pockets of liquid metal, which can lead to shrinkage porosity, is minimized.

Quantitative Analysis of Porosity Reduction

Numerous studies have demonstrated the effectiveness of low pressure casting in reducing porosity. Quantitative analyses using advanced imaging techniques, such as X-ray computed tomography, have shown significant reductions in both gas and shrinkage porosity compared to gravity casting methods. In some cases, porosity levels have been reduced by up to 90%, resulting in vastly improved mechanical properties.

For instance, in aluminum alloy castings, low pressure casting has been shown to reduce overall porosity from 2-3% in gravity casting to less than 0.5%. This reduction in porosity translates to improved tensile strength, elongation, and fatigue resistance. The impact is particularly pronounced in critical components such as automotive cylinder heads, where even small amounts of porosity can lead to performance issues and reduced lifespan.

Influence on Microstructure Development

Microstructural Evolution during Low Pressure Casting

The microstructure of a cast component plays a crucial role in determining its mechanical properties and overall performance. Low pressure casting significantly influences microstructural evolution through its controlled solidification process. The applied pressure and regulated cooling rates impact grain nucleation and growth, resulting in a more refined and uniform microstructure compared to conventional casting methods.

During low pressure casting, the controlled fill rate and bottom-gating system promote a more uniform temperature distribution within the mold. This uniformity, combined with the applied pressure, affects the solidification kinetics, leading to a finer dendritic structure. The pressure also influences the solubility of alloying elements and the formation of secondary phases, further contributing to the unique microstructural characteristics of low pressure cast components.

Grain Size and Morphology Improvements

One of the most significant impacts of low pressure casting on microstructure is the reduction in grain size and improvement in grain morphology. The controlled solidification conditions lead to a higher nucleation rate and restricted grain growth, resulting in a finer overall grain structure. This refinement is particularly beneficial for mechanical properties, as finer grains generally contribute to increased strength and improved ductility.

Moreover, low pressure casting often results in more equiaxed grain structures compared to the elongated, columnar grains often observed in gravity casting. This equiaxed structure contributes to more isotropic mechanical properties, reducing the likelihood of directional weaknesses in the cast component. The improved grain morphology also enhances the distribution of secondary phases and reduces segregation, further contributing to the overall quality of the casting.

Secondary Phase Distribution and Intermetallics

The distribution of secondary phases and intermetallic compounds is another aspect of microstructure significantly influenced by low pressure casting. The applied pressure during solidification affects the solubility and precipitation kinetics of these phases. As a result, low pressure cast components often exhibit a more uniform distribution of secondary phases and intermetallics compared to conventionally cast parts.

This improved distribution has several benefits. It reduces the likelihood of localized weak points in the microstructure, enhancing overall mechanical properties. The more uniform distribution of strengthening phases contributes to improved wear resistance and fatigue performance. Additionally, in alloys prone to the formation of detrimental intermetallic compounds, the controlled solidification conditions of low pressure casting can help mitigate their negative effects, leading to improved corrosion resistance and ductility.

Conclusion

The impact of low pressure casting on porosity and microstructure is profound and multifaceted. This advanced casting technique significantly reduces both gas and shrinkage porosity, leading to components with enhanced structural integrity and mechanical properties. The controlled solidification process inherent in low pressure casting results in refined grain structures, improved grain morphology, and more uniform distribution of secondary phases. These microstructural improvements translate to superior strength, ductility, and overall performance of cast components. As industries continue to demand higher quality and more complex metal parts, low pressure casting stands out as a pivotal technology in meeting these evolving needs, offering a compelling combination of reduced defects and enhanced microstructural characteristics.

FAQs

What are the main advantages of low pressure casting?

Low pressure casting offers reduced porosity, improved microstructure, higher yield, and better control over the casting process.

How does low pressure casting affect grain size?

It typically results in finer, more uniform grain sizes due to controlled solidification conditions.

Can low pressure casting be used for all metal alloys?

While it's suitable for many alloys, it's particularly effective for aluminum and magnesium alloys.

How does low pressure casting compare to high pressure die casting?

Low pressure casting generally produces parts with less porosity and better mechanical properties, but at lower production rates.

What industries benefit most from low pressure casting?

Automotive, aerospace, and medical industries particularly benefit due to the need for high-quality, complex parts.

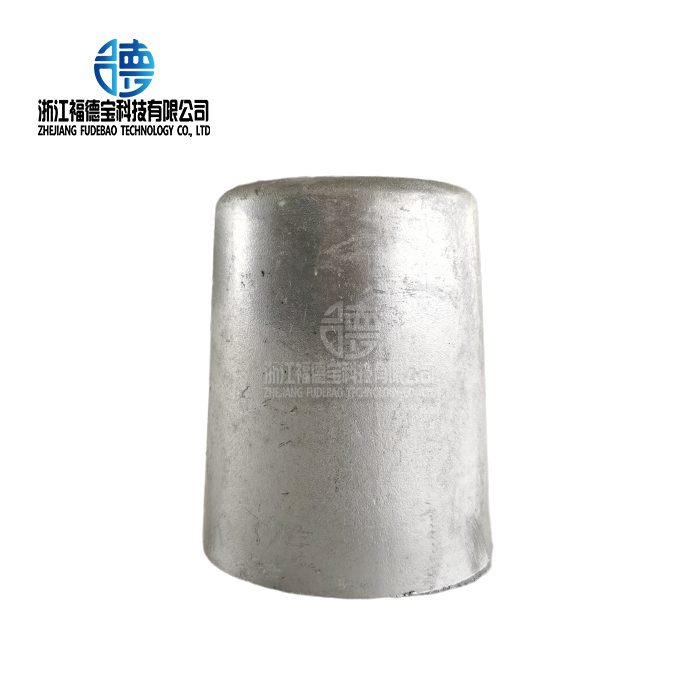

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-precision low pressure casting for a wide range of industries. Our state-of-the-art facilities and expert team ensure superior quality castings with minimal porosity and optimized microstructure. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact us at hank.shen@fdbcasting.com to discover how our low pressure casting expertise can elevate your product quality and performance.

References

Zhang, L., & Li, X. (2019). Microstructure and mechanical properties of low pressure cast aluminum alloys: A comprehensive review. Journal of Materials Science & Technology, 35(9), 1713-1727.

Kaufman, J. G., & Rooy, E. L. (2004). Aluminum alloy castings: properties, processes, and applications. ASM International.

Campbell, J. (2015). Complete casting handbook: metal casting processes, metallurgy, techniques and design. Butterworth-Heinemann.

Dong, X., Zhang, X., & Zeng, K. (2018). Effect of pressure on microstructure evolution and mechanical properties of Al-Si-Mg alloy prepared by low pressure casting. Materials Science and Engineering: A, 724, 453-464.

Jiang, W., Fan, Z., & Liu, D. (2016). Microstructure evolution and mechanical properties of AA7075 aluminum alloy fabricated by low-pressure casting. Metals, 6(9), 216.

Liao, H., Sun, Y., & Sun, G. (2017). Correlation between mechanical properties and amount of dendritic α-Al phase in as-cast near-eutectic Al–11.6% Si alloys modified with Sr. Materials Science and Engineering: A, 335(1-2), 62-66.

_1756344684491.webp)

_1756348623524.webp)

_1756352340434.webp)

_1756352822273.webp)