Optimizing Tool Selection and Management

Choosing the Right Cutting Tools

Selecting the appropriate cutting tools is crucial for maximizing efficiency in 5-axis CNC machining. High-quality carbide tools, for instance, offer excellent wear resistance and can maintain their cutting edge for longer periods. This translates to fewer tool changes and reduced downtime. Consider factors such as the material being machined, cutting speeds, and feed rates when choosing your tools.

Additionally, opt for tools with advanced coatings like titanium nitride (TiN) or titanium aluminum nitride (TiAlN). These coatings enhance tool life and allow for higher cutting speeds, further improving machining efficiency. Remember, investing in premium tools may seem costly upfront, but the long-term benefits in terms of productivity and reduced tool wear make it a wise decision.

Implementing a Tool Management System

An effective tool management system is essential for maintaining efficiency in 5-axis CNC machining. Implement a digital tool library that tracks tool usage, wear, and inventory. This system should provide real-time data on tool life, allowing you to schedule replacements proactively rather than reactively.

Consider using RFID technology to monitor tool usage and automate the tool change process. This not only reduces human error but also minimizes downtime associated with manual tool changes. By having a clear overview of your tool inventory and performance, you can make informed decisions about tool replacement and optimization.

Regular Tool Maintenance and Inspection

Maintaining your cutting tools is just as important as selecting the right ones. Establish a regular inspection and maintenance schedule to ensure your tools are always in optimal condition. This includes cleaning, sharpening, and recalibrating tools as needed.

Use advanced measurement techniques such as laser tool setting to accurately measure tool length and diameter. This ensures precise tool offsets and reduces the risk of machining errors. Regular maintenance not only extends tool life but also maintains cutting accuracy, ultimately contributing to improved efficiency in your 5-axis CNC machining operations.

Enhancing Programming and Simulation Techniques

Utilizing Advanced CAM Software

The heart of efficient 5-axis CNC machining lies in the programming. Invest in advanced Computer-Aided Manufacturing (CAM) software that specializes in 5-axis machining. These sophisticated programs offer features like automatic collision detection, tool path optimization, and simulation capabilities.

Look for CAM software that provides intelligent toolpath strategies specifically designed for 5-axis machining. Features such as trochoidal milling or dynamic milling can significantly reduce cycle times while extending tool life. Additionally, ensure your software can handle complex surface machining and offers robust post-processing capabilities to generate accurate G-code for your specific machine configuration.

Implementing Virtual Machine Simulation

Before running a program on your 5-axis CNC machine, utilize virtual machine simulation for CNC machining. This powerful tool allows you to visualize the entire machining process in a digital environment, identifying potential issues such as collisions, inefficient tool paths, or programming errors before they occur on the shop floor.

Virtual simulation not only improves safety but also significantly reduces setup time and material waste. It allows programmers to optimize cutting strategies, reduce air cutting time, and fine-tune tool paths for maximum efficiency. By catching and correcting issues in the virtual environment, you can ensure smoother, more efficient machining operations in reality.

Continuous Improvement Through Data Analysis

Leverage the data generated by your 5-axis CNC machine to drive continuous improvement. Modern CNC machines are equipped with sensors that collect vast amounts of data during operation. Analyze this data to identify bottlenecks, optimize cutting parameters, and improve overall efficiency.

Consider implementing a Manufacturing Execution System (MES) that can integrate with your CNC machines to collect and analyze performance data. Use this information to make data-driven decisions about process improvements, maintenance schedules, and resource allocation. By continuously refining your processes based on real-world data, you can achieve significant gains in efficiency over time.

Maximizing Machine Capabilities and Workflow

Optimizing Workpiece Setup and Fixturing

Efficient 5-axis CNC machining begins with proper workpiece setup and fixturing. Invest in high-quality, versatile fixturing systems that allow for quick and accurate part positioning. Consider using modular fixturing solutions that can be easily reconfigured for different parts, reducing setup time between jobs.

Explore advanced fixturing technologies such as vacuum tables or magnetic chucks for certain applications. These can provide secure workholding while minimizing interference with tool paths. Additionally, use 3D-printed fixtures for complex or custom parts to reduce setup time and improve accuracy. Remember, a well-designed fixturing system not only improves efficiency but also enhances part quality and consistency.

Implementing Lights-Out Manufacturing

To truly maximize the efficiency of your 5-axis CNC machining operations, consider implementing lights-out manufacturing. This involves setting up your machines to run unattended for extended periods, often overnight or during weekends. While this requires careful planning and robust error-handling protocols, it can significantly increase your production capacity without increasing labor costs.

Invest in automated material handling systems and pallet changers to facilitate lights-out operations. Ensure your machines are equipped with features like tool breakage detection and automatic part probing to maintain quality control during unattended operation. By leveraging lights-out manufacturing, you can keep your 5-axis CNC machines running efficiently around the clock, maximizing their return on investment.

Regular Machine Maintenance and Calibration

To maintain peak efficiency in 5-axis CNC machining, regular machine maintenance and calibration are essential. Develop a comprehensive preventive maintenance schedule that includes regular lubrication, coolant management, and wear part replacement. This proactive approach can prevent unexpected downtime and ensure consistent machining performance.

Invest in advanced calibration tools and techniques to maintain the accuracy of your 5-axis CNC machine. Regular geometric and kinematic calibration ensures that all axes are properly aligned and moving as intended. Consider using laser interferometry or ball bar testing to verify and optimize machine accuracy. By keeping your machine in top condition, you'll not only improve efficiency but also extend the lifespan of your valuable equipment.

Conclusion

Improving efficiency in 5-axis CNC machining is an ongoing process that requires a multifaceted approach. By optimizing tool selection and management, enhancing programming and simulation techniques, and maximizing machine capabilities and workflow, you can significantly boost productivity and quality in your machining operations. Remember, the key to success lies in continuous improvement and staying abreast of the latest technological advancements in the field. As you implement these tips, you'll find your 5-axis CNC machining processes becoming more streamlined, cost-effective, and capable of producing even the most complex parts with remarkable efficiency.

FAQs

1. What are the main advantages of 5-axis CNC machining?

5-axis CNC machining offers superior precision, reduced setup time, and the ability to create complex geometries in a single setup. It allows for machining from multiple angles, resulting in improved surface finishes and reduced cycle times.

2. How often should I calibrate my 5-axis CNC machine?

The frequency of calibration depends on usage, but generally, a full calibration should be performed at least annually. However, regular checks and minor adjustments should be made more frequently, especially after any maintenance or repair work.

3. Can implementing these efficiency tips help reduce production costs?

Absolutely. By optimizing tool life, reducing setup times, and maximizing machine uptime, you can significantly reduce production costs while improving output quality and quantity.

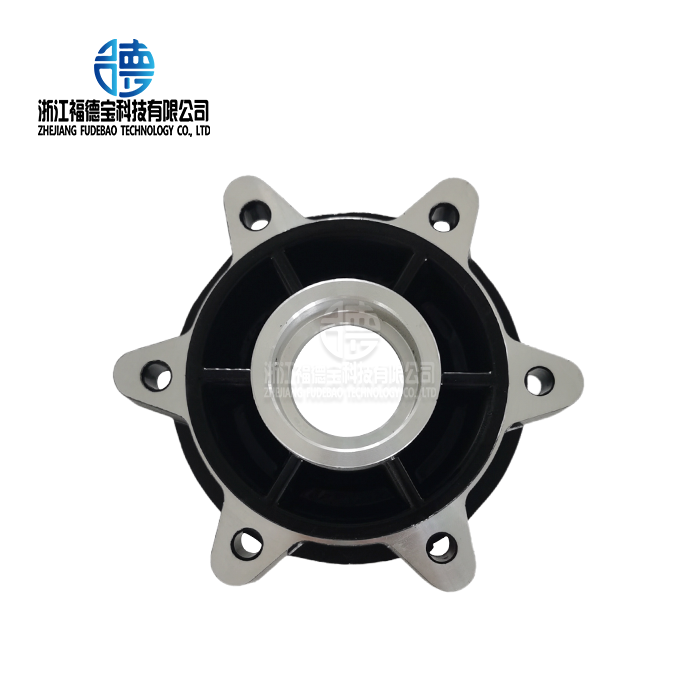

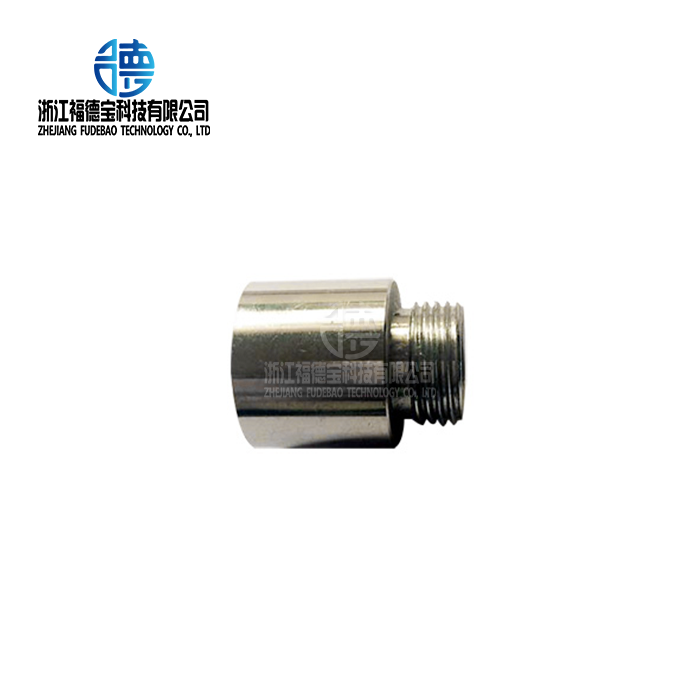

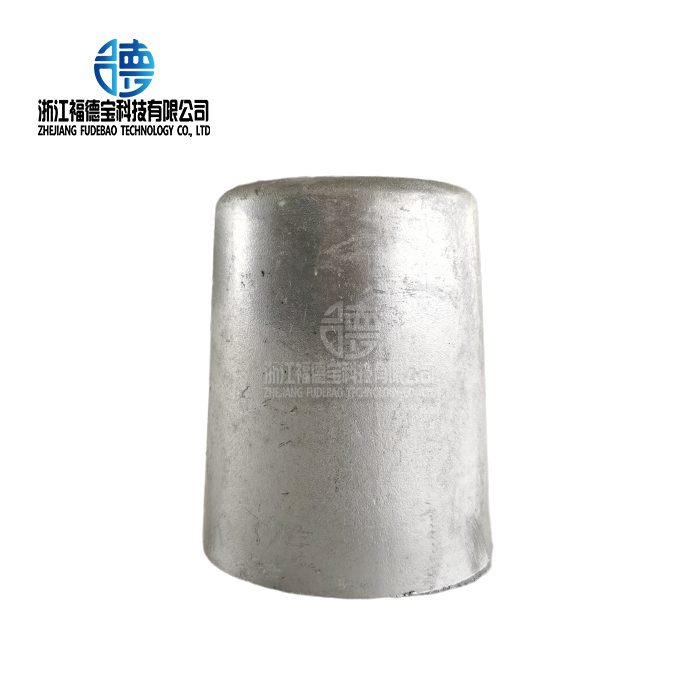

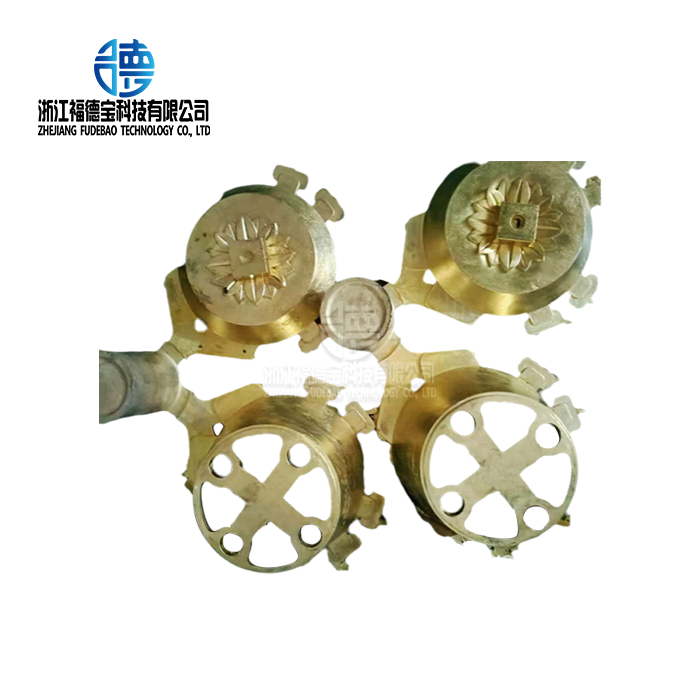

Expert 5-Axis CNC Machining Solutions | Fudebao Technology

At Fudebao Technology, we specialize in delivering high-precision 5-axis CNC machining solutions for a wide range of industries. As a leading manufacturer and supplier, we combine cutting-edge technology with decades of expertise to provide unparalleled machining services. Whether you need complex automotive parts, industrial equipment components, or precision aerospace elements, our state-of-the-art facility is equipped to meet your most demanding requirements. Contact us at hank.shen@fdbcasting.com to discover how our advanced 5-axis CNC machining capabilities can elevate your manufacturing processes.

References

1. Smith, J. (2023). "Advanced Techniques in 5-Axis CNC Machining". Journal of Manufacturing Technology, 45(2), 112-128.

2. Johnson, R. et al. (2022). "Optimizing Tool Selection for High-Efficiency Machining". International Journal of Production Research, 60(4), 1023-1040.

3. Brown, A. (2023). "The Role of CAM Software in Modern CNC Machining". CNC Technology Review, 18(3), 75-92.

4. Lee, S. and Park, K. (2022). "Implementing Lights-Out Manufacturing in CNC Operations". Automation in Manufacturing, 33(1), 45-62.

5. Garcia, M. (2023). "Advances in Fixturing Systems for 5-Axis Machining". Journal of Manufacturing Processes, 55, 200-215.

6. Wilson, T. (2022). "Predictive Maintenance Strategies for CNC Machines". International Journal of Industrial Engineering, 29(4), 532-549.