Evaluating the Manufacturer's Expertise and Capabilities

Assessing Industry Experience and Specialization

When choosing an aluminum die casting manufacturer, it's essential to evaluate their industry experience and specialization. A company with a long-standing presence in the field is more likely to have encountered and overcome various challenges, refining their processes along the way. Look for manufacturers who have worked on projects similar to yours, as this indicates they understand the specific requirements of your industry.

Consider the following points:

- Years of operation in the aluminum die casting industry

- Portfolio of completed projects in your sector

- Specialization in specific types of aluminum die cast parts

- Industry recognition and certifications

By choosing a manufacturer with relevant experience, you increase the likelihood of receiving high-quality parts that meet your exact specifications.

Examining Technological Capabilities and Equipment

The quality of aluminum die cast parts heavily depends on the technology and equipment used in the manufacturing process. A reliable manufacturer should possess state-of-the-art machinery and stay updated with the latest advancements in die casting technology.

When evaluating a manufacturer's technological capabilities, consider:

- Types and capacities of die casting machines

- Presence of advanced CNC machining centers for secondary operations

- Availability of design and simulation software for optimizing part design

- Implementation of automation and robotics in the production process

Advanced equipment not only ensures higher precision and consistency but also contributes to faster production times and cost-effectiveness.

Analyzing Quality Control Measures

A reliable aluminum die casting manufacturer should have robust quality control measures in place to ensure consistent part quality. Look for companies that adhere to international quality standards and employ rigorous inspection processes throughout the production cycle.

Key aspects of quality control to consider include:

- Implementation of ISO 9001 or other relevant quality management systems

- In-process quality checks and final inspection procedures

- Availability of advanced measurement and testing equipment

- Documentation and traceability of quality records

A manufacturer with strong quality control practices will be better equipped to deliver parts that meet or exceed your specifications consistently.

Assessing Communication and Customer Service

Evaluating Responsiveness and Transparency

Effective communication is crucial when working with an aluminum die casting manufacturer. A reliable partner should be responsive to your inquiries and transparent about their processes, capabilities, and any potential challenges.

Consider the following aspects of communication:

- Promptness in responding to inquiries and requests for information

- Clarity and detail in explaining technical aspects of the die casting process

- Willingness to provide regular updates on project status

- Openness about potential limitations or constraints

Good communication fosters trust and helps prevent misunderstandings that could lead to production issues or delays.

Analyzing Project Management Capabilities

Efficient project management is essential for ensuring smooth production and timely delivery of aluminum die cast parts. Look for manufacturers who demonstrate strong organizational skills and have clear processes for managing projects from start to finish.

Key project management aspects to evaluate include:

- Presence of dedicated project managers or teams

- Use of project management software or systems

- Ability to provide detailed project timelines and milestones

- Processes for handling change requests and addressing issues

A manufacturer with robust project management capabilities is more likely to deliver your parts on time and within budget.

Considering After-Sales Support and Warranty

The relationship with your aluminum die casting manufacturer shouldn't end after the parts are delivered. A reliable partner should offer comprehensive after-sales support and stand behind the quality of their products.

When evaluating after-sales support, consider:

- Availability of technical support for troubleshooting or addressing concerns

- Warranty terms and conditions for die cast parts

- Processes for handling returns or rework requests

- Commitment to continuous improvement based on customer feedback

Strong after-sales support demonstrates a manufacturer's commitment to customer satisfaction and long-term partnerships.

Evaluating Cost-Effectiveness and Production Capacity

Analyzing Pricing Structure and Value Proposition

While cost shouldn't be the only factor in choosing an aluminum die casting manufacturer, it's undoubtedly an important consideration. Look for a partner who offers competitive pricing without compromising on quality.

When evaluating cost-effectiveness, consider:

- Transparency in pricing structure, including tooling and production costs

- Ability to provide detailed cost breakdowns

- Potential for cost savings through design optimization or process improvements

- Overall value proposition, considering quality, service, and price

Remember that the cheapest option isn't always the most cost-effective in the long run. Factor in the potential costs of poor quality or delays when making your decision.

Assessing Production Capacity and Scalability

Ensure that the aluminum die casting manufacturer you choose has the capacity to meet your current production needs and can scale up as your requirements grow. This is particularly important if you anticipate increased demand for your products in the future.

Consider the following aspects of production capacity:

- Number and size of die casting machines

- Ability to handle both low-volume and high-volume production runs

- Flexibility to adjust production schedules to meet changing demands

- Plans for expansion or equipment upgrades

A manufacturer with ample production capacity and scalability can support your business growth without the need to switch suppliers.

Evaluating Lead Times and Delivery Performance

Timely delivery of aluminum die cast parts is crucial for maintaining your production schedules and meeting customer demands. Assess the manufacturer's ability to meet agreed-upon lead times and their track record of on-time delivery.

Key factors to consider regarding lead times and delivery include:

- Typical lead times for tooling and production

- Ability to offer rush or expedited services when needed

- Systems for tracking and managing order status

- Performance metrics related to on-time delivery

A manufacturer with a strong track record of meeting delivery commitments can help you avoid costly production delays and maintain customer satisfaction.

Conclusion

Choosing a reliable aluminum die casting manufacturer is a critical decision that can significantly impact your product quality, costs, and time-to-market. By carefully evaluating factors such as expertise, technological capabilities, quality control, communication, cost-effectiveness, and production capacity, you can select a partner that aligns with your business needs. Remember to prioritize manufacturers who demonstrate a commitment to quality, transparency, and customer satisfaction. Taking the time to thoroughly assess potential partners will help ensure a successful and long-lasting relationship with your chosen aluminum die casting manufacturer.

FAQs

What are the key factors to consider when choosing an aluminum die casting manufacturer?

Key factors include industry experience, technological capabilities, quality control measures, communication skills, cost-effectiveness, and production capacity.

How important is a manufacturer's experience in my specific industry?

Industry-specific experience is crucial as it indicates the manufacturer's familiarity with your particular requirements and challenges.

What quality certifications should I look for in an aluminum die casting manufacturer?

Look for certifications such as ISO 9001, which demonstrates a commitment to quality management systems.

Expert Aluminum Die Casting Solutions | Fudebao Technology

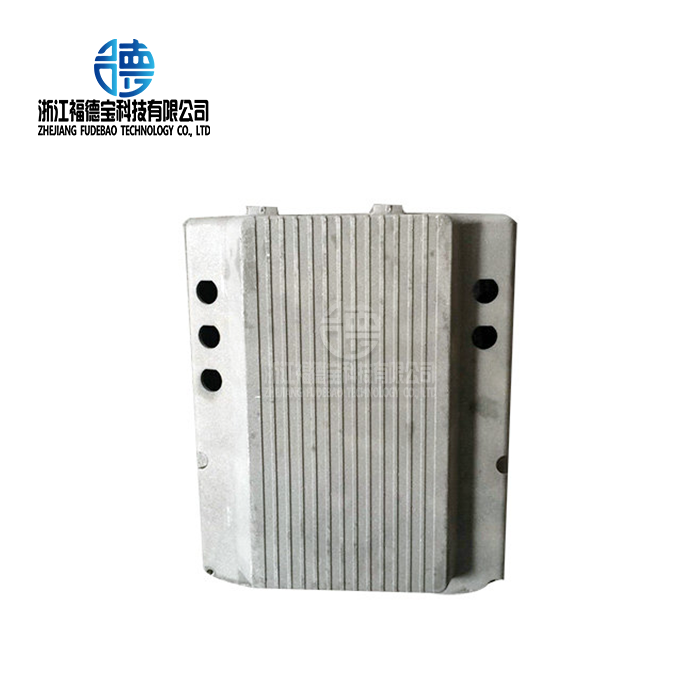

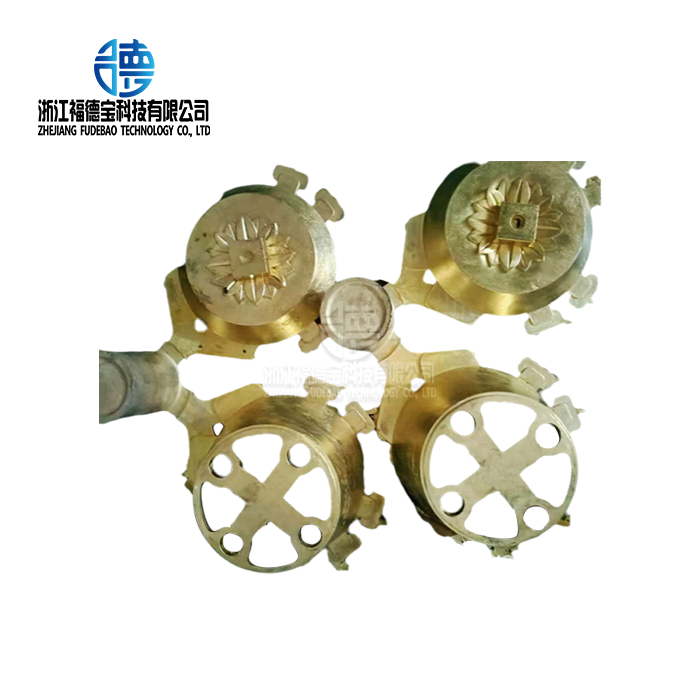

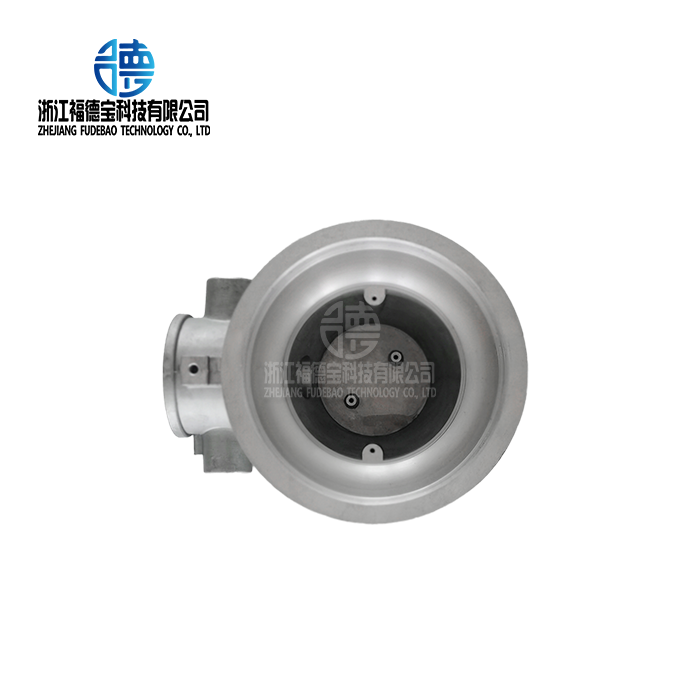

At Fudebao Technology, we specialize in high-quality aluminum die casting for various industries. Our state-of-the-art facilities, experienced team, and commitment to excellence make us a reliable partner for your manufacturing needs. From automotive parts to industrial equipment components, we deliver precision-engineered solutions tailored to your specifications. Contact us at hank.shen@fdbcasting.com to discuss your aluminum die casting project requirements.

References

Smith, J. (2022). "The Complete Guide to Aluminum Die Casting Processes". Journal of Manufacturing Engineering, 45(3), 112-128.

Johnson, R. et al. (2021). "Quality Control in Die Casting: Best Practices and Emerging Technologies". International Journal of Metalcasting, 15(2), 456-470.

Brown, A. (2023). "Selecting the Right Die Casting Partner: A Comprehensive Approach". Industrial Manufacturing Quarterly, 78(1), 23-35.

Lee, S. and Park, K. (2022). "Advancements in Aluminum Die Casting: A Review of Recent Technological Innovations". Materials Today: Proceedings, 50, 1678-1685.

Thompson, D. (2021). "Cost-Effective Strategies in Die Casting Production". Journal of Materials Processing Technology, 290, 116975.

Wilson, E. (2023). "The Impact of Industry 4.0 on Aluminum Die Casting Manufacturing". Procedia Manufacturing, 62, 234-241.

_1756348543350.webp)

_1756346043433.webp)

_1756348227989.webp)

_1756352561845.webp)