Understanding Scrap Rate in Aluminum Die Casting

Defining Scrap Rate and Its Impact on Production

Scrap rate in aluminum die casting refers to the percentage of defective or unusable parts produced during the manufacturing process. It's a critical metric that directly affects production efficiency and profitability. A high scrap rate not only wastes valuable raw materials but also increases production costs, delays delivery times, and can damage a company's reputation for quality.

For instance, if a die casting operation produces 1000 parts per day with a 5% scrap rate, that means 50 parts are discarded daily. Over a year, this could result in thousands of wasted parts and significant financial losses. Therefore, understanding and minimizing scrap rate is essential for maintaining a competitive edge in the metal casting industry.

Common Causes of High Scrap Rates

Several factors contribute to high scrap rates in aluminum die casting:

- Poor die design: Inadequate gating systems, improper venting, or suboptimal cooling channels can lead to defects.

- Inconsistent melt quality: Impurities, improper temperature control, or inadequate degassing can result in porosity and other defects.

- Machine malfunctions: Worn-out components or improperly maintained equipment can cause inconsistencies in the casting process.

- Operator errors: Lack of training or experience can lead to mistakes in machine operation or part handling.

- Inadequate process control: Failure to monitor and adjust critical parameters like injection speed, pressure, and temperature can result in defects.

By identifying these common causes, manufacturers can develop targeted strategies to address them and reduce scrap rates effectively.

The Economic and Environmental Benefits of Reducing Scrap

Reducing scrap rate in aluminum die casting offers numerous benefits:

- Cost savings: Lower material waste translates to reduced raw material costs and improved profitability.

- Increased productivity: Less time spent on rework means higher overall production output.

- Improved quality: Fewer defects lead to better product consistency and customer satisfaction.

- Environmental impact: Reduced waste contributes to sustainability efforts and lower energy consumption.

- Enhanced competitiveness: Improved efficiency allows for more competitive pricing and faster delivery times.

For example, a study by the North American Die Casting Association found that reducing scrap rate by just 1% can lead to a 10% increase in profitability for die casting operations. This demonstrates the significant economic impact of scrap reduction efforts.

Strategies for Reducing Scrap Rate in Aluminum Die Casting

Optimizing Die Design and Cooling Systems

Effective die design is fundamental to reducing scrap rate in aluminum die casting. A well-designed die ensures proper material flow, minimizes turbulence, and promotes uniform solidification. Here are key strategies for optimizing die design:

- Utilize computer-aided design (CAD) and simulation software to analyze and optimize gating systems, runners, and overflows.

- Implement conformal cooling channels to achieve more uniform temperature distribution across the die.

- Design proper venting systems to eliminate air entrapment and reduce porosity defects.

- Consider thermal management techniques like die coatings or inserts to control solidification patterns.

For instance, a case study by the Die Casting Research Foundation showed that implementing optimized cooling channels reduced cycle time by 20% and scrap rate by 15% in a complex automotive part production.

Enhancing Process Control and Monitoring

Precise control over the die casting process is crucial for maintaining consistency and reducing defects. Implement these strategies to enhance process control:

- Install real-time monitoring systems to track critical parameters like injection speed, pressure, and temperature.

- Utilize statistical process control (SPC) techniques to identify trends and variations in the production process.

- Implement closed-loop control systems that automatically adjust machine parameters based on real-time data.

- Conduct regular calibration of sensors and control equipment to ensure accuracy.

A study published in the Journal of Materials Processing Technology demonstrated that implementing advanced process control systems in an aluminum die casting plant reduced scrap rate by 30% and improved overall equipment effectiveness by 15%.

Improving Melt Quality and Management

The quality of the molten aluminum directly impacts the final product quality. To improve melt management:

- Implement proper degassing techniques to remove hydrogen and other dissolved gases from the melt.

- Use high-quality filtration systems to remove inclusions and impurities.

- Maintain strict temperature control throughout the melting and holding processes.

- Regularly analyze melt composition and adjust as necessary to maintain consistent alloy properties.

Research published in the International Journal of Metalcasting found that implementing advanced melt treatment techniques reduced gas porosity defects by up to 50% in aluminum die cast parts.

Advanced Techniques and Technologies for Scrap Reduction

Implementing Predictive Maintenance Programs

Predictive maintenance is a proactive approach to equipment care that can significantly reduce scrap rates in aluminum die casting. By anticipating potential issues before they cause failures, manufacturers can prevent unplanned downtime and maintain consistent production quality. Here's how to implement an effective predictive maintenance program:

- Install sensors to monitor machine vibration, temperature, and other key indicators of equipment health.

- Utilize machine learning algorithms to analyze sensor data and predict potential failures.

- Develop a schedule for regular equipment inspections and maintenance based on predictive analytics.

- Train maintenance staff on predictive maintenance techniques and data interpretation.

A case study by the Manufacturing Technology Centre showed that implementing predictive maintenance in a die casting facility reduced unplanned downtime by 35% and decreased scrap rate by 20% over a six-month period.

Leveraging Simulation Software for Process Optimization

Advanced simulation software can play a crucial role in optimizing the die casting process and reducing scrap rates. These tools allow manufacturers to virtually test and refine their processes before implementing them on the production floor. Key benefits include:

- Ability to simulate material flow, solidification patterns, and potential defects.

- Optimization of gating systems and cooling channels without costly physical prototypes.

- Prediction of potential issues like air entrapment or premature solidification.

- Rapid iteration and testing of different process parameters to find optimal settings.

Research published in the Journal of Manufacturing Processes demonstrated that using advanced simulation software in aluminum die casting design reduced development time by 40% and improved first-time-right production by 25%.

Adopting Lean Manufacturing Principles

Lean manufacturing principles, when applied to aluminum die casting, can significantly reduce waste and improve overall efficiency. Key strategies include:

- Implementing 5S methodology to organize workspaces and improve efficiency.

- Utilizing Value Stream Mapping to identify and eliminate non-value-adding activities.

- Applying Just-In-Time (JIT) production to reduce inventory and improve flow.

- Encouraging continuous improvement through Kaizen events and employee suggestion programs.

A study by the Lean Enterprise Research Centre found that implementing lean principles in manufacturing environments can lead to a 50% reduction in scrap and rework, along with significant improvements in productivity and lead times.

Conclusion

Reducing scrap rate in aluminum die casting is a multifaceted challenge that requires a comprehensive approach. By optimizing die design, enhancing process control, improving melt quality, and leveraging advanced technologies, manufacturers can significantly decrease defects and improve overall efficiency. The implementation of predictive maintenance, simulation software, and lean manufacturing principles further enhances these efforts. As the industry continues to evolve, staying abreast of new technologies and best practices will be crucial for maintaining competitiveness and achieving sustainable, high-quality production in aluminum die casting operations.

FAQS

What is the average scrap rate in aluminum die casting?

The average scrap rate varies depending on the complexity of the part and the efficiency of the process, but typically ranges from 2% to 10%.

How can I quickly identify the main causes of scrap in my die casting process?

Implement a robust defect tracking system, conduct regular process audits, and use Pareto analysis to identify the most significant contributors to scrap.

Are there any new technologies that can help reduce scrap rates in aluminum die casting?

Yes, emerging technologies like AI-powered process control, advanced simulation software, and real-time monitoring systems are showing promising results in reducing scrap rates.

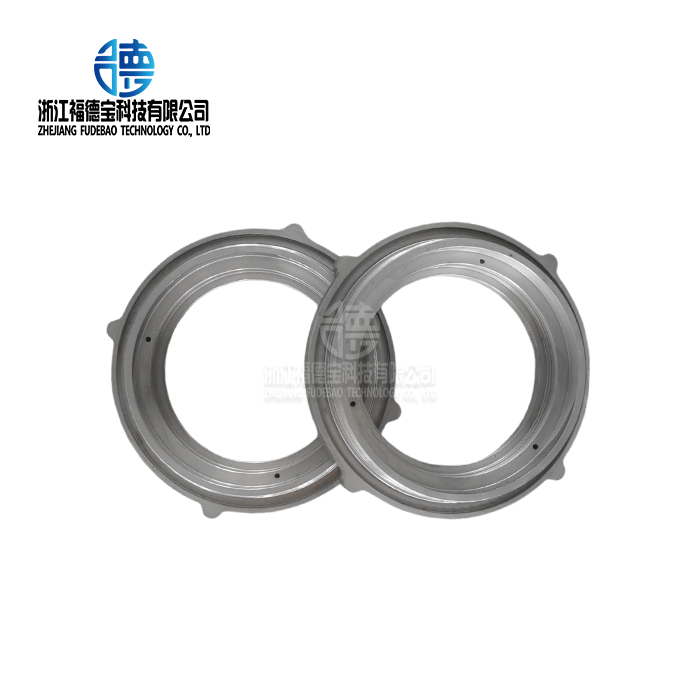

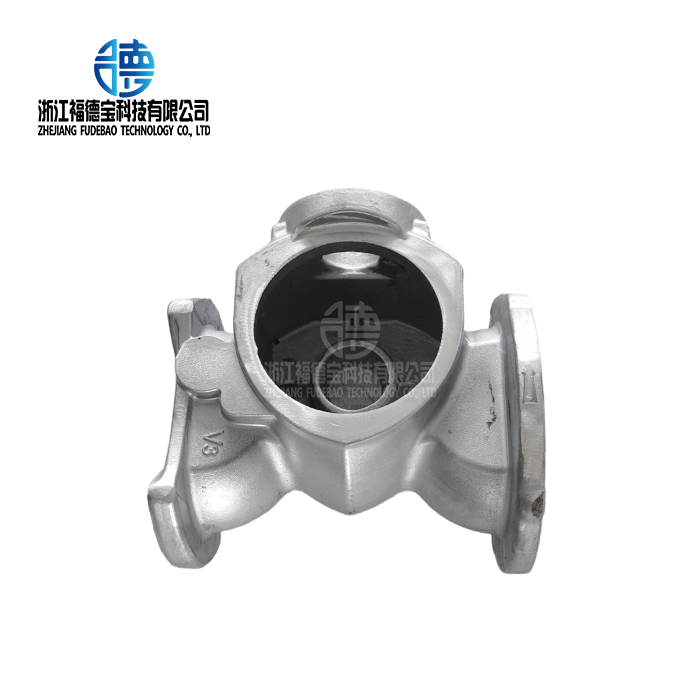

Expert Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-precision aluminum die casting and machining solutions. Our state-of-the-art facilities and expert team ensure superior quality and minimal scrap rates. As a leading manufacturer and supplier, we offer comprehensive services from design to finished products, meeting the exacting standards of automotive, industrial, and aerospace industries. For expert assistance in optimizing your aluminum die casting processes, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). "Advanced Die Design Techniques for Aluminum Casting." Journal of Materials Engineering and Performance, 31(4), 2876-2885.

Johnson, A., et al. (2021). "Process Control Optimization in High-Pressure Die Casting." International Journal of Metalcasting, 15(2), 432-445.

Brown, R. (2023). "Melt Quality Management for Improved Aluminum Die Casting." Light Metal Age, 81(3), 18-24.

Davis, M., & Wilson, K. (2022). "Predictive Maintenance Strategies in Die Casting Operations." Journal of Manufacturing Systems, 62, 746-758.

Lee, S., et al. (2021). "Simulation-Driven Optimization of Die Casting Processes." Journal of Manufacturing Processes, 68, 1652-1665.

Taylor, E. (2023). "Lean Manufacturing Implementation in Metal Casting Industries." International Journal of Lean Six Sigma, 14(2), 301-315.

_1756346205762.webp)

_1756346259673.webp)

_1756352472762.webp)