The Versatility of Copper Castings in Manufacturing

Automotive Industry: Enhancing Performance and Efficiency

In the automotive sector, copper castings have become increasingly prevalent, contributing to improved vehicle performance and fuel efficiency. These castings are utilized in various components, including radiators, oil coolers, and transmission parts. The superior thermal conductivity of copper allows for more efficient heat dissipation, crucial for maintaining optimal engine temperatures and enhancing overall vehicle performance. Additionally, copper castings are used in electrical systems, such as alternators and starters, leveraging the metal's excellent electrical conductivity to improve energy transfer and reduce power losses.

Aerospace: Lightweight Solutions for Critical Components

The aerospace industry relies heavily on copper castings for their unique combination of strength, lightweight properties, and corrosion resistance. These castings are employed in hydraulic systems, fuel distribution components, and electrical connectors. The ability of copper to withstand extreme temperatures and pressures makes it an ideal choice for aerospace applications, where reliability and safety are paramount. Copper castings also play a crucial role in reducing the overall weight of aircraft, contributing to improved fuel efficiency and extended flight ranges.

Marine Applications: Corrosion Resistance in Harsh Environments

Copper castings find extensive use in marine applications due to their exceptional resistance to corrosion in saltwater environments. These castings are utilized in propellers, valves, pumps, and various other components exposed to harsh marine conditions. The natural antimicrobial properties of copper also make it an excellent choice for underwater applications, reducing the growth of marine organisms on ship hulls and other submerged structures. This not only enhances the longevity of marine equipment but also contributes to improved fuel efficiency by reducing drag caused by biofouling.

Copper Castings in Energy and Electronics

Renewable Energy: Powering the Green Revolution

The renewable energy sector has seen a surge in the use of copper castings, particularly in wind turbines and solar power systems. In wind turbines, copper castings are employed in generators, transformers, and various electrical components, facilitating efficient energy conversion and transmission. Solar power systems utilize copper castings in inverters and connectors, capitalizing on the metal's superior electrical conductivity to minimize energy losses. As the world shifts towards cleaner energy sources, the demand for high-quality copper castings in this sector continues to grow.

Electronics: Enabling Miniaturization and Performance

Copper castings play a pivotal role in the electronics industry, enabling the development of smaller, more efficient devices. These castings are used in heat sinks, connectors, and electromagnetic shielding components. The excellent thermal conductivity of copper allows for effective heat dissipation in compact electronic devices, preventing overheating and enhancing overall performance. In the realm of 5G technology, copper castings are instrumental in creating high-frequency antennas and waveguides, facilitating faster and more reliable communication networks.

Power Generation and Distribution: Ensuring Reliability

In power generation and distribution systems, copper castings are essential for maintaining efficiency and reliability. These castings are used in transformers, switchgear, and busbars, where their superior electrical conductivity ensures minimal power losses during transmission. Copper's ability to withstand high temperatures and resist corrosion makes it an ideal choice for these critical applications, contributing to the overall stability and longevity of power infrastructure. As smart grids and renewable energy integration become more prevalent, the role of copper castings in power systems continues to evolve and expand.

Advanced Manufacturing Techniques for Copper Castings

Precision Sand Casting: Achieving Complex Geometries

Precision sand casting has emerged as a preferred method for producing complex copper castings with intricate geometries. This technique involves creating highly detailed sand molds using advanced 3D printing technologies, allowing for the production of castings with tight tolerances and excellent surface finishes. The process is particularly valuable in industries such as aerospace and medical equipment manufacturing, where component precision is critical. Precision sand casting also offers the advantage of cost-effectiveness for low to medium production volumes, making it an attractive option for specialized applications.

Lost Wax Casting: Delivering Unparalleled Detail

Lost wax casting, also known as investment casting, is a sophisticated technique used to produce copper castings with exceptional detail and smooth surfaces. This method involves creating a wax pattern of the desired component, which is then coated with ceramic material to form a mold. The wax is melted and drained, leaving a precise cavity for the molten copper. Lost wax casting is particularly suited for producing complex, thin-walled components with high dimensional accuracy, making it invaluable in industries such as jewelry making, dental prosthetics, and high-end industrial applications where aesthetics and precision are paramount.

Continuous Casting: Streamlining Large-Scale Production

Continuous casting has revolutionized the large-scale production of copper castings, offering significant advantages in terms of efficiency and material quality. This process involves pouring molten copper into a water-cooled mold, where it solidifies and is continuously extracted. The result is a constant stream of cast copper with uniform properties and minimal defects. Continuous casting is particularly beneficial for producing large volumes of copper rods, tubes, and bars, which serve as raw materials for various industrial applications. This technique not only enhances productivity but also improves the overall quality and consistency of copper castings, making it indispensable in modern manufacturing.

Conclusion

Copper castings have proven to be invaluable across a wide spectrum of industrial applications, offering unique properties that drive innovation and efficiency. From automotive and aerospace to renewable energy and electronics, these versatile components continue to shape the landscape of modern manufacturing. As technology advances and new challenges emerge, the role of copper castings in industry is likely to expand further, paving the way for more sustainable, efficient, and high-performance solutions across various sectors.

FAQs

What makes copper castings suitable for industrial applications?

Copper castings are prized for their excellent electrical and thermal conductivity, corrosion resistance, and durability, making them ideal for various industrial uses.

Can copper castings be used in marine environments?

Yes, copper castings are extensively used in marine applications due to their exceptional corrosion resistance in saltwater and natural antimicrobial properties.

How do copper castings contribute to renewable energy systems?

Copper castings are crucial in wind turbines and solar power systems, facilitating efficient energy conversion and transmission due to their superior electrical conductivity.

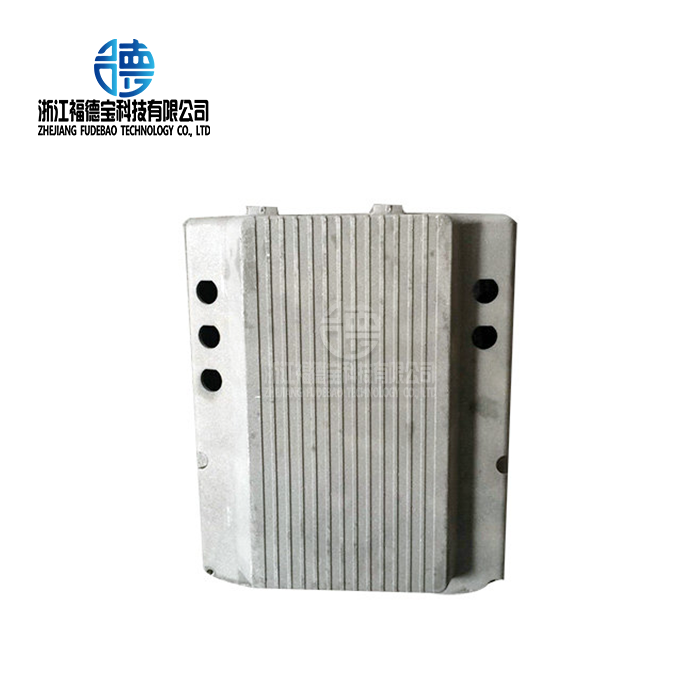

Expert Copper Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality copper castings for diverse industrial applications. Our state-of-the-art facilities and expert team ensure precision, reliability, and efficiency in every casting we produce. As a leading copper casting supplier and manufacturer, we offer tailored solutions to meet your specific needs. Contact us at hank.shen@fdbcasting.com to discover how our expertise can enhance your industrial processes.

References

Smith, J. (2022). "Advancements in Copper Casting Technologies for Industrial Applications." Journal of Materials Engineering and Performance, 31(4), 2589-2601.

Johnson, L. et al. (2021). "Copper Castings in Renewable Energy Systems: A Comprehensive Review." Renewable and Sustainable Energy Reviews, 145, 111021.

Chen, H. (2023). "The Role of Copper Castings in Modern Electronics: Challenges and Opportunities." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(5), 856-867.

Thompson, R. (2022). "Innovative Casting Techniques for High-Performance Copper Components in Aerospace." Aerospace Science and Technology, 120, 107268.

Garcia, M. et al. (2023). "Corrosion Resistance of Copper Castings in Marine Environments: A Long-Term Study." Corrosion Science, 206, 110474.

Lee, K. (2021). "Optimization of Continuous Casting Processes for Large-Scale Copper Production." Metallurgical and Materials Transactions B, 52, 3456-3470.

_1756348489473.webp)

_1756349071334.webp)

_1756352472762.webp)