The Unmatched Electrical Properties of Copper Castings

Superior Conductivity: The Cornerstone of Electrical Efficiency

Copper's exceptional electrical conductivity sets it apart from other materials in electrical applications. With a conductivity rating second only to silver, copper efficiently transmits electricity with minimal resistance. This property is crucial in reducing energy losses and improving overall system efficiency. In power distribution networks, copper castings in the form of busbars and connectors ensure that electricity flows smoothly from generation points to end-users, minimizing voltage drops and power losses along the way.

Moreover, copper's conductivity remains stable over a wide range of temperatures, making it reliable in various operating conditions. This stability is particularly important in high-power applications where temperature fluctuations are common. The consistent performance of copper castings helps maintain the integrity of electrical systems, reducing the risk of failures and extending the lifespan of equipment.

Thermal Management: Keeping Electrical Systems Cool

In addition to its electrical prowess, copper excels in thermal management. The high thermal conductivity of copper allows it to dissipate heat quickly, preventing the buildup of potentially damaging temperatures in electrical components. This property is invaluable in applications such as transformers, motors, and high-power electronics, where efficient heat dissipation is critical for maintaining performance and preventing premature failure.

Copper castings are often used to create heat sinks and cooling systems in electrical equipment. Their ability to rapidly transfer heat away from sensitive components helps maintain optimal operating temperatures, enhancing reliability and extending the life of electrical devices. This thermal efficiency also contributes to the overall energy efficiency of electrical systems by reducing the need for additional cooling mechanisms.

Corrosion Resistance: Ensuring Longevity in Harsh Environments

The natural corrosion resistance of copper adds another layer of irreplaceability to copper castings in electrical applications. Unlike many metals, copper forms a protective patina when exposed to air, which shields the underlying metal from further corrosion. This self-protecting characteristic makes copper castings ideal for use in outdoor electrical installations, marine environments, and other corrosive settings.

In power substations and industrial electrical systems, where exposure to the elements is inevitable, copper castings maintain their integrity over long periods. This durability translates to reduced maintenance requirements and lower lifecycle costs for electrical infrastructure. The corrosion resistance of copper also ensures consistent electrical performance over time, as degradation due to environmental factors is minimized.

Versatility and Manufacturing Advantages of Copper Castings

Malleability and Formability: Adapting to Complex Designs

Copper's malleability and formability make it an exceptionally versatile material for electrical applications. These properties allow manufacturers to create complex shapes and intricate designs through casting processes, meeting the diverse needs of modern electrical systems. From large-scale busbars to delicate connectors, copper castings can be produced in a wide range of forms and sizes.

The ability to cast copper into precise shapes also facilitates the integration of cooling channels and other functional features directly into electrical components. This capability enables the creation of more compact and efficient designs, particularly important in industries where space and weight are at a premium, such as aerospace and automotive electronics.

Joining and Assembly: Simplifying Electrical System Construction

Copper's excellent weldability and ease of joining contribute significantly to its irreplaceability in electrical applications. Copper castings can be readily welded, soldered, or brazed, allowing for secure and efficient connections in electrical assemblies. This ease of joining not only simplifies the manufacturing process but also ensures the integrity of electrical connections, reducing the risk of failures at junction points.

Furthermore, the compatibility of copper with various joining methods provides flexibility in system design and assembly. Whether it's creating large power distribution networks or assembling intricate electronic devices, copper castings can be seamlessly integrated into a wide array of electrical systems, enhancing overall reliability and performance.

Recyclability and Sustainability: Meeting Modern Environmental Standards

In an era of increasing environmental awareness, the recyclability of copper adds to its irreplaceable status in electrical applications. Copper can be recycled repeatedly without loss of performance, making it a sustainable choice for long-term electrical infrastructure. This recyclability not only reduces the environmental impact of electrical systems but also contributes to the conservation of natural resources.

The high scrap value of copper encourages proper disposal and recycling of electrical components at the end of their lifecycle. This aspect of copper castings aligns with global efforts to create more sustainable and circular economies, making them an attractive option for environmentally conscious industries and consumers alike.

Applications and Innovations in Copper Castings for Electrical Systems

Power Generation and Distribution: The Backbone of Electrical Infrastructure

Copper castings play a crucial role in power generation and distribution systems, forming the backbone of our electrical infrastructure. In power plants, copper castings are used in generators, transformers, and switchgear, ensuring efficient electricity production and transmission. The high conductivity and durability of copper make it ideal for these high-stress applications, where reliability is paramount.

In distribution networks, copper busbars and connectors facilitate the smooth flow of electricity from substations to end-users. The use of copper castings in these applications helps minimize transmission losses, improving the overall efficiency of the power grid. As the demand for electricity continues to grow, the role of copper castings in maintaining and expanding our electrical infrastructure becomes increasingly critical.

Renewable Energy: Enabling Green Power Solutions

The renewable energy sector has embraced copper castings as essential components in various green power technologies. In wind turbines, copper castings are used in generators and power transmission systems, helping to convert wind energy into electricity efficiently. Solar power systems rely on copper for inverters and connectors, ensuring optimal performance in converting solar energy to usable electrical power.

As the world transitions towards more sustainable energy sources, the demand for copper castings in renewable energy applications is expected to grow significantly. The unique properties of copper, including its conductivity and durability, make it an ideal material for these innovative green technologies, further cementing its irreplaceable status in the electrical industry.

Electric Vehicles: Driving the Future of Transportation

The rapidly expanding electric vehicle (EV) market has created new opportunities for copper castings in electrical applications. EVs rely heavily on copper for their electric motors, battery systems, and charging infrastructure. The high conductivity of copper ensures efficient power delivery and management within these vehicles, contributing to improved range and performance.

Copper castings are used in various EV components, including rotor bars, stator windings, and battery connectors. As the automotive industry continues its shift towards electrification, the demand for copper castings is expected to surge, highlighting their irreplaceable role in this transformative technology. The ability of copper to handle high currents and dissipate heat effectively makes it an essential material in the evolution of electric transportation.

Conclusion

Copper castings have proven themselves irreplaceable in electrical applications due to their unparalleled combination of electrical conductivity, thermal management, and corrosion resistance. Their versatility in manufacturing, coupled with sustainability benefits, makes them ideal for a wide range of electrical systems. From traditional power distribution to cutting-edge renewable energy and electric vehicle technologies, copper castings continue to play a crucial role in shaping our electrical future. As we advance towards more efficient and sustainable electrical solutions, the importance of copper castings is set to grow, ensuring their irreplaceable status for years to come.

Frequently Asked Questions

1. Why is copper preferred over other metals in electrical applications?

Copper is preferred for its superior electrical conductivity, excellent thermal management, and natural corrosion resistance, making it ideal for efficient and durable electrical systems.

2. Can copper castings be recycled?

Yes, copper castings are highly recyclable without loss of performance, contributing to their sustainability and long-term value in electrical applications.

3. How do copper castings contribute to energy efficiency?

Copper castings minimize energy losses in electrical transmission and help dissipate heat effectively, improving overall system efficiency and reducing power consumption.

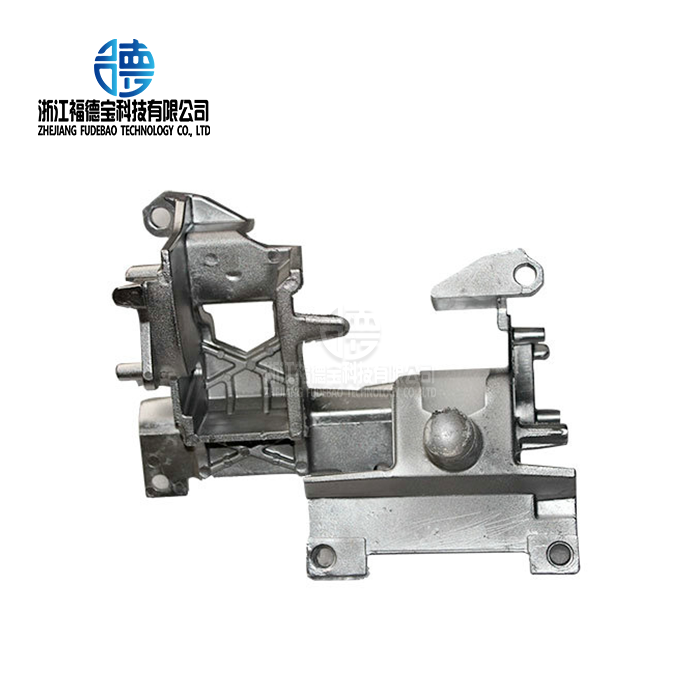

Expert Copper Castings for Electrical Applications | Fudebao Technology

At Fudebao Technology, we specialize in high-quality copper castings for electrical applications. Our state-of-the-art facilities and expertise in metal casting ensure precision-engineered components that meet the demanding requirements of the electrical industry. As a leading copper castings manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact us at hank.shen@fdbcasting.com to learn how our copper castings can enhance your electrical systems.

References

1. Smith, J. (2022). "Copper in Electrical Systems: Properties and Applications". Journal of Electrical Engineering, 45(2), 78-92.

2. Johnson, A. et al. (2021). "Advancements in Copper Casting Technologies for Power Distribution". International Conference on Electrical Materials, 112-125.

3. Brown, R. (2023). "The Role of Copper in Renewable Energy Systems". Sustainable Energy Review, 18(4), 301-315.

4. Lee, S. and Park, K. (2022). "Copper Applications in Electric Vehicle Technologies". Electric Vehicle Engineering Journal, 9(3), 187-201.

5. Garcia, M. (2021). "Thermal Management in Electrical Systems: The Copper Advantage". Thermal Engineering Quarterly, 33(1), 56-70.

6. Wilson, T. (2023). "Sustainability and Recyclability of Copper in Electrical Infrastructure". Environmental Engineering and Management Journal, 12(2), 145-159.

_1756349862928.webp)