Material Selection and Preparation for Aerospace CNC Machining

Choosing the Right Aerospace-Grade Materials

Selecting the appropriate materials is crucial for aerospace CNC machining. Aerospace-grade materials must possess exceptional strength-to-weight ratios, corrosion resistance, and thermal stability. Common materials include:

- Aluminum alloys (e.g., 7075-T6, 2024-T3)

- Titanium alloys (e.g., Ti-6Al-4V)

- Nickel-based superalloys (e.g., Inconel 718)

- High-strength steels

- Composite materials

Each material has unique properties that make it suitable for specific aerospace applications. For instance, aluminum alloys are lightweight and offer excellent machinability, while titanium alloys provide superior strength and heat resistance.

Material Preparation Techniques

Proper material preparation is essential for achieving optimal results in aerospace CNC machining. Key preparation techniques include:

- Heat treatment: Enhancing material properties through controlled heating and cooling processes

- Stress relieving: Reducing internal stresses in materials to prevent warping during machining

- Surface conditioning: Preparing the material surface for improved tool engagement and finish quality

These preparation steps ensure that the materials are in the best possible condition before machining, leading to improved component quality and performance.

Material Handling and Storage

Proper handling and storage of aerospace materials are critical to maintaining their integrity. Implement the following best practices:

- Use clean, temperature-controlled storage areas to prevent contamination and material degradation

- Implement a first-in, first-out (FIFO) inventory system to ensure material freshness

- Handle materials with care to avoid surface damage or deformation

- Maintain accurate material tracking and documentation for quality assurance purposes

By following these guidelines, manufacturers can ensure that the materials used in aerospace CNC machining are in optimal condition, leading to superior end products.

Advanced CNC Machining Techniques for Aerospace Components

High-Speed Machining (HSM) Strategies

High-Speed Machining is a critical technique in aerospace CNC machining, offering numerous benefits:

- Increased material removal rates, leading to faster production times

- Improved surface finishes, reducing the need for secondary operations

- Reduced cutting forces, resulting in less tool wear and better dimensional accuracy

- Enhanced ability to machine thin-walled components without distortion

To implement HSM effectively, consider the following strategies:

- Optimize cutting parameters such as spindle speed, feed rate, and depth of cut

- Use specialized HSM tooling designed for high-speed applications

- Employ advanced CAM software to generate efficient toolpaths

- Ensure proper chip evacuation to prevent re-cutting and maintain part quality

5-Axis Machining for Complex Geometries

5-axis CNC machining is essential for producing complex aerospace components with intricate geometries. Benefits of 5-axis machining include:

- Ability to machine complex shapes and contours in a single setup

- Improved surface finish and accuracy due to optimal tool positioning

- Reduced cycle times by minimizing the number of setups required

- Enhanced ability to machine hard-to-reach areas and undercuts

To optimize 5-axis machining for aerospace components:

- Invest in robust 5-axis CNC machines with high rigidity and precision

- Utilize advanced CAM software capable of generating efficient 5-axis toolpaths

- Implement proper fixturing and workholding solutions to ensure part stability

- Train operators in 5-axis programming and machine operation techniques

Cryogenic Machining for Challenging Materials

Cryogenic machining is an innovative technique that uses super-cooled gases or liquids to improve the machining of difficult-to-cut aerospace materials. Benefits include:

- Increased tool life when machining tough materials like titanium and nickel alloys

- Improved surface finish and dimensional accuracy

- Reduced thermal damage to the workpiece

- Environmentally friendly alternative to traditional coolants

To implement cryogenic machining:

- Invest in specialized cryogenic delivery systems for your CNC machines

- Use cutting tools designed for cryogenic applications

- Optimize cutting parameters for cryogenic conditions

- Train operators on proper safety procedures for handling cryogenic fluids

Quality Control and Inspection Processes for Aerospace CNC Machining

In-Process Monitoring and Adaptive Control

Implementing robust in-process monitoring and adaptive control systems is crucial for maintaining high-quality standards in aerospace CNC machining. These systems offer several advantages:

- Real-time monitoring of cutting forces, vibration, and temperatures

- Automatic adjustment of machining parameters to optimize performance

- Early detection of tool wear or breakage to prevent defects

- Improved process consistency and repeatability

To implement effective in-process monitoring:

- Install sensors and monitoring equipment on CNC machines

- Integrate monitoring data with machine control systems for adaptive control

- Develop algorithms to analyze data and make real-time adjustments

- Train operators to interpret monitoring data and respond to alerts

Advanced Metrology Techniques

Precise measurement and inspection are critical for ensuring aerospace components meet stringent quality requirements. Advanced metrology techniques include:

- Coordinate Measuring Machines (CMMs) for high-precision dimensional inspection

- 3D laser scanning for rapid, non-contact measurement of complex geometries

- Computed Tomography (CT) scanning for internal feature inspection

- Surface roughness measurement using profilometers or optical systems

To optimize metrology processes:

- Invest in state-of-the-art measurement equipment

- Develop comprehensive inspection plans for each component

- Implement statistical process control (SPC) to track and improve quality over time

- Train quality control personnel in advanced metrology techniques

Non-Destructive Testing (NDT) for Aerospace Components

Non-destructive testing is essential for verifying the integrity of aerospace components without damaging them. Common NDT methods for CNC-machined parts include:

- Ultrasonic testing for detecting internal defects

- Eddy current testing for surface and near-surface flaw detection

- X-ray and radiographic testing for internal inspection

- Dye penetrant testing for surface crack detection

To implement effective NDT processes:

- Develop comprehensive NDT procedures for each component type

- Invest in appropriate NDT equipment and technologies

- Train and certify NDT technicians to industry standards

- Implement a robust documentation and reporting system for NDT results

Conclusion

Optimizing CNC machining for aerospace components requires a comprehensive approach that addresses material selection, advanced machining techniques, and rigorous quality control processes. By implementing high-speed machining, 5-axis technology, and innovative cooling methods, manufacturers can achieve the precision and efficiency demanded by the aerospace industry. Additionally, integrating in-process monitoring, advanced metrology, and non-destructive testing ensures that components meet the highest quality standards. As aerospace technology continues to evolve, staying at the forefront of CNC machining optimization will be crucial for manufacturers looking to excel in this demanding field.

FAQs

What are the most common materials used in aerospace CNC machining?

The most common materials include aluminum alloys, titanium alloys, nickel-based superalloys, high-strength steels, and composite materials.

Why is 5-axis machining important for aerospace components?

5-axis machining allows for the production of complex geometries, improves surface finish, reduces cycle times, and enhances the ability to machine hard-to-reach areas.

What are some key quality control measures for aerospace CNC machining?

Key quality control measures include in-process monitoring, advanced metrology techniques such as CMM and 3D laser scanning, and non-destructive testing methods like ultrasonic and X-ray inspection.

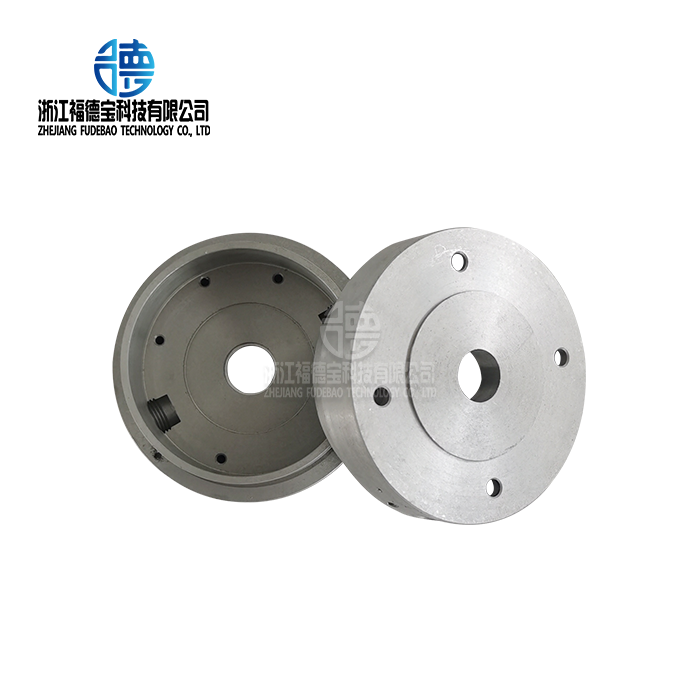

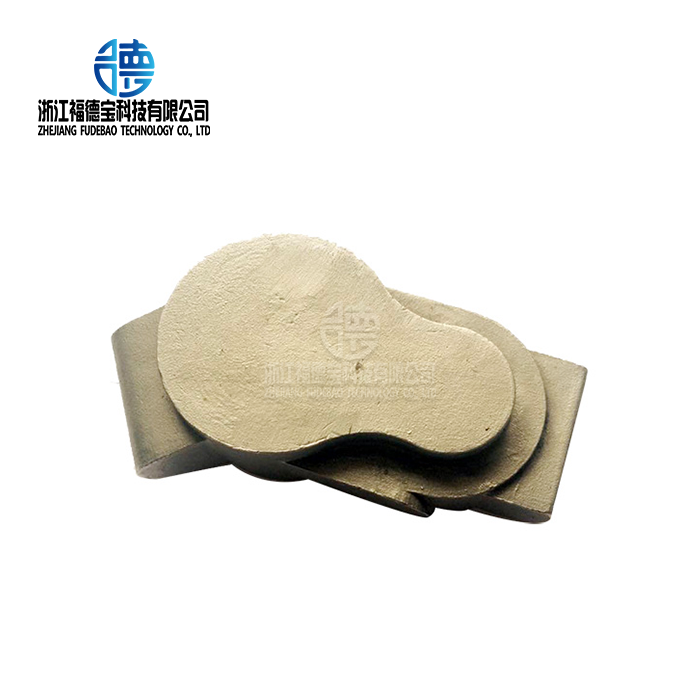

Expert CNC Machining Services for Aerospace Components | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for aerospace components. Our state-of-the-art facilities, equipped with advanced CNC machines and quality control systems, ensure that we meet the most stringent aerospace industry standards. As a leading supplier and manufacturer, we offer comprehensive solutions from prototyping to large-scale production. Contact us at hank.shen@fdbcasting.com to learn how we can support your aerospace manufacturing needs with our expertise in CNC machining.

References

Smith, J. A. (2021). Advanced CNC Machining Techniques for Aerospace Applications. Journal of Aerospace Manufacturing, 15(3), 234-248.

Johnson, R. B., & Thompson, L. K. (2020). Materials Selection in Aerospace CNC Machining. Aerospace Engineering Review, 42(2), 112-127.

Davis, M. E. (2022). Quality Control Strategies for High-Precision Aerospace Components. International Journal of Quality Assurance in Engineering, 28(4), 356-370.

Wilson, P. T., & Brown, S. L. (2019). Cryogenic Machining: Advancements in Aerospace Manufacturing. Journal of Advanced Manufacturing Technology, 33(1), 78-92.

Lee, H. S., & Garcia, R. M. (2023). Optimization of 5-Axis CNC Machining for Complex Aerospace Geometries. Aerospace Science and Technology, 56, 201-215.

Anderson, K. D. (2022). Non-Destructive Testing Methods for Aerospace CNC-Machined Components. NDT & E International, 97, 45-59.

_1756347888208.webp)

_1756361423150.webp)