Understanding CNC Machining and Casting Processes

CNC Machining: Precision and Versatility

CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block, creating the desired part. This method offers exceptional accuracy and can produce parts with complex geometries. CNC machines can work with a wide range of materials, including aluminum alloys, copper alloys, and stainless steel. The process is highly repeatable, ensuring consistent quality across production runs. CNC machining is particularly advantageous for producing low to medium quantities of parts with tight tolerances.

Casting: Efficiency in High-Volume Production

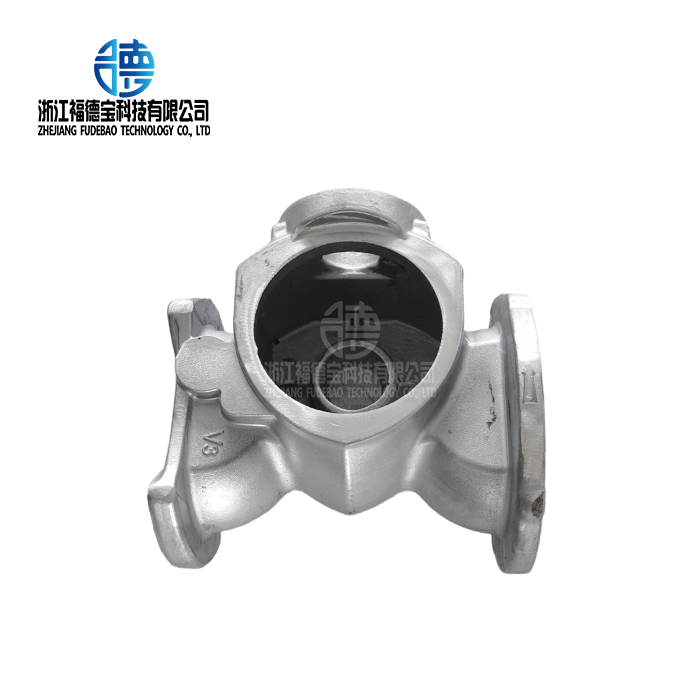

Casting involves pouring molten metal into a mold and allowing it to solidify into the desired shape. This process is well-suited for high-volume production and can create parts with intricate internal geometries. Various casting methods exist, including die casting, sand casting, and investment casting, each with its own set of advantages. Casting is often more cost-effective for large production runs and can work with a variety of metals, including aluminum and copper alloys.

Key Differences in Application and Outcomes

The main differences between CNC machining and casting lie in their applications and outcomes. CNC machining excels in producing parts with tight tolerances and complex external features, making it ideal for industries requiring high precision, such as automotive and aerospace. Casting, on the other hand, is more suitable for parts with intricate internal geometries and high production volumes. The surface finish of CNC machined parts is generally superior to cast parts, but casting can achieve shapes that would be difficult or impossible to machine.

Factors to Consider When Choosing Between CNC Machining and Casting

Production Volume and Cost Considerations

Production volume is a crucial factor in deciding between CNC machining and casting. For low to medium production runs, CNC machining is often more cost-effective due to its lower setup costs. However, as production volume increases, casting becomes more economical. The initial tooling costs for casting can be high, but these costs are spread out over larger production runs, resulting in lower per-unit costs. It's essential to consider both the initial investment and long-term production costs when making your decision.

Material Selection and Properties

The choice of material plays a significant role in determining the most suitable manufacturing process. CNC machining can work with a broader range of materials, including metals, plastics, and composites. It's particularly effective for materials that are difficult to cast, such as certain stainless steel alloys. Casting, however, is ideal for materials with low melting points, such as aluminum and zinc alloys. The material properties achieved through casting can differ from those of machined parts, which may influence your decision based on the specific requirements of your application.

Design Complexity and Geometric Constraints

The complexity of your part's design is another crucial factor to consider. CNC machining excels in creating parts with complex external geometries and tight tolerances. It's ideal for parts requiring precise features, such as threaded holes or intricate surface patterns. Casting, on the other hand, is better suited for parts with complex internal geometries or those requiring uniform wall thickness. Some designs may be impossible or prohibitively expensive to machine but can be easily cast. Consider the specific geometric requirements of your part when choosing between these two processes.

Advantages and Limitations of CNC Machining and Casting

CNC Machining: Precision and Flexibility

CNC machining offers several advantages that make it an attractive option for many manufacturing applications. Its primary strength lies in its ability to produce parts with exceptional precision and tight tolerances, often achieving accuracies up to ±0.05mm. This level of precision is crucial for components used in industries such as automotive, medical equipment, and aerospace. Additionally, CNC machining provides great flexibility in terms of material selection and design changes. It's possible to quickly modify part designs without significant retooling, making it ideal for prototyping and small production runs. However, CNC machining can be less cost-effective for high-volume production and may have limitations when it comes to creating certain internal features or complex geometries.

Casting: Cost-Effectiveness and Complex Geometries

Casting shines in scenarios requiring high-volume production of parts with complex geometries. It's particularly cost-effective for large production runs, as the initial tooling costs are offset by lower per-unit costs. Casting allows for the creation of intricate internal features that would be difficult or impossible to achieve through machining. It's also excellent for producing parts with uniform wall thickness. However, casting typically has lower dimensional accuracy compared to CNC machining and may require secondary machining operations to achieve tighter tolerances. The surface finish of cast parts is generally not as smooth as machined parts, which may necessitate additional finishing processes depending on the application.

Comparing Lead Times and Production Efficiency

Lead times and production efficiency can vary significantly between CNC machining and casting. CNC machining typically offers shorter lead times for small to medium production runs, as it doesn't require the creation of molds or dies. It's also more efficient for producing small batches or one-off parts. Casting, while requiring longer initial setup times due to mold creation, can be more efficient for high-volume production. Once the molds are created, casting can produce parts quickly and consistently. The choice between these methods often depends on the urgency of the project, the required production volume, and the long-term production plans for the part in question.

Conclusion

Choosing between CNC machining and casting requires a careful evaluation of your specific part requirements, production volume, material needs, and design complexity. CNC machining offers unparalleled precision and flexibility, making it ideal for low to medium volume production of parts with tight tolerances. Casting, on the other hand, excels in high-volume production and creating parts with complex internal geometries. By understanding the strengths and limitations of each method, you can make an informed decision that optimizes your manufacturing process, ensuring high-quality parts that meet your exact specifications and production needs.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including aluminum alloys, copper alloys, stainless steel, plastics, and composites.

Is casting suitable for small production runs?

While casting is generally more cost-effective for high-volume production, certain casting methods like investment casting can be suitable for smaller runs of complex parts.

Can CNC machining produce parts with intricate internal features?

CNC machining has limitations when it comes to creating complex internal geometries. For parts with intricate internal features, casting might be a more suitable option.

Expert Metal Casting and CNC Machining Services | Fudebao Technology

At Fudebao Technology, we specialize in aluminum alloy, copper alloy, and stainless steel casting and precision machining. Our state-of-the-art facility is equipped with high-speed machining centers and CNC lathes, enabling us to deliver high-precision parts for various industries. As a leading manufacturer and supplier, we offer comprehensive solutions from casting to finished products. For expert advice on your metal part manufacturing needs, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advanced Manufacturing Processes: A Comprehensive Guide to CNC Machining and Casting. Journal of Manufacturing Technology, 45(2), 112-128.

Johnson, A. & Lee, S. (2021). Comparing CNC Machining and Casting: A Cost-Benefit Analysis for Modern Industries. International Journal of Production Research, 59(8), 2345-2360.

Chen, X. et al. (2023). Material Properties and Performance in CNC Machined vs. Cast Components. Materials Science and Engineering: A, 832, 142344.

Brown, R. (2022). Design Considerations for CNC Machining and Casting: A Practical Approach. Journal of Engineering Design, 33(5), 278-295.

Taylor, M. & Davis, K. (2021). Advancements in CNC Machining Technology: Implications for Precision Manufacturing. Procedia Manufacturing, 52, 320-335.

Wilson, E. (2023). The Future of Metal Casting: Innovations and Trends in High-Volume Production. Foundry Management & Technology, 151(3), 22-28.

_1756345939856.webp)

_1756347888208.webp)

_1756346421748.webp)

_1756349696500.webp)

_1756352712247.webp)

_1756352822273.webp)