Understanding Aluminum Casting Heat Treatment Processes

Solution Treatment: Preparing the Microstructure

Solution treatment is the first step in the heat treatment process for aluminum castings. This stage involves heating the casting to a temperature just below its melting point and holding it there for a specific duration. The purpose is to dissolve alloying elements into the aluminum matrix, creating a supersaturated solid solution.

During solution treatment, several key changes occur in the microstructure:

- Dissolution of precipitates

- Homogenization of the alloy composition

- Reduction of segregation effects

The temperature and duration of solution treatment are critical factors that influence the final properties of the casting. Typically, temperatures range from 460°C to 550°C (860°F to 1022°F), depending on the specific alloy composition.

Quenching: Freezing the Supersaturated State

Following solution treatment, the aluminum casting undergoes rapid cooling for aluminum castings, known as quenching. This process is crucial for maintaining the supersaturated solid solution created during the solution treatment phase. Quenching prevents the immediate formation of precipitates, effectively "freezing" the alloying elements in place within the aluminum matrix.

Common quenching methods include:

- Water quenching

- Air quenching

- Polymer quenching

The choice of quenching medium and rate significantly affects the final hardness and strength of the casting. Rapid quenching generally results in higher hardness but may introduce residual stresses that need to be managed.

Aging: Developing Hardness Through Precipitation

The final stage of heat treatment is aging, which can be either natural (at room temperature) or artificial (at elevated temperatures). During aging, controlled precipitation of alloying elements occurs, forming fine, dispersed particles throughout the aluminum matrix.

These precipitates act as obstacles to dislocation movement, effectively increasing the hardness and strength of the aluminum casting. The aging process can be fine-tuned to achieve specific hardness levels by adjusting:

- Aging temperature

- Aging time

- Single or multi-step aging sequences

For example, T6 heat treatment, a common process for aluminum castings, typically involves artificial aging at temperatures between 150°C and 190°C (302°F to 374°F) for several hours.

Factors Influencing Hardness in Heat-Treated Aluminum Castings

Alloy Composition: The Foundation of Hardness Potential

The chemical composition of an aluminum alloy plays a fundamental role in determining its hardness potential through heat treatment. Different alloying elements contribute uniquely to the hardening mechanisms:

- Copper (Cu): Enhances age-hardening response

- Magnesium (Mg): Improves strength-to-weight ratio

- Silicon (Si): Increases fluidity and reduces shrinkage

- Zinc (Zn): Boosts overall strength and hardness

For instance, Al-Cu alloys like 2xx.x series are known for their excellent response to heat treatment, achieving high hardness levels. In contrast, Al-Si alloys like the 3xx.x series offer good castability and moderate heat treatment response.

Cooling Rate: Balancing Hardness and Residual Stress

The cooling rate during quenching significantly impacts the final hardness of aluminum castings. Faster cooling rates generally result in higher hardness due to the formation of a finer microstructure and more effective supersaturation of the solid solution. However, rapid cooling can also introduce residual stresses that may compromise the casting's dimensional stability or lead to distortion.

Factors affecting cooling rate include:

- Quenchant type (e.g., water, oil, air)

- Quenchant temperature

- Agitation level

- Casting geometry and section thickness

Optimizing the cooling rate involves finding a balance between achieving desired hardness levels and minimizing residual stresses. This often requires careful consideration of the specific alloy and part geometry.

Aging Parameters: Fine-Tuning Hardness Development

The aging process is where the final hardness of aluminum castings is developed through controlled precipitation. The interplay between aging temperature, time, and precipitation kinetics determines the ultimate hardness achieved.

Key considerations in aging include:

- Peak aging: Achieving maximum hardness

- Over-aging: Deliberate aging beyond peak hardness for improved ductility

- Under-aging: Stopping the aging process before peak hardness for specific property combinations

For example, in T6 heat treatment, aging temperatures typically range from 150°C to 190°C (302°F to 374°F) for 2-12 hours, depending on the alloy and desired properties. Higher aging temperatures generally accelerate hardness development but may lead to a lower peak hardness.

Optimizing Heat Treatment for Desired Hardness in Aluminum Castings

Tailoring Heat Treatment Cycles for Specific Applications

Optimizing heat treatment cycles for aluminum castings involves carefully balancing various parameters to achieve the desired hardness and other mechanical properties. This process requires a deep understanding of the relationship between heat treatment variables and the resulting microstructure.

Key steps in tailoring heat treatment cycles include:

- Analyzing application requirements (e.g., wear resistance, fatigue strength)

- Selecting appropriate solution treatment temperatures and times

- Determining optimal quenching methods

- Fine-tuning aging parameters for desired hardness levels

For instance, automotive pistons might require a T6 heat treatment with extended aging to maximize hardness and wear resistance, while aerospace components might benefit from a T7 treatment that sacrifices some peak hardness for improved dimensional stability.

Controlling Microstructure for Enhanced Hardness

The microstructure of aluminum castings plays a crucial role in determining their hardness and overall mechanical properties. Heat treatment processes can be optimized to control various aspects of the microstructure, including:

- Grain size and morphology

- Precipitate size, distribution, and coherency

- Secondary phase formation and dissolution

Advanced techniques such as electron microscopy and X-ray diffraction can be employed to analyze and fine-tune the microstructure. For example, achieving a uniform distribution of fine, coherent precipitates through carefully controlled aging can significantly enhance hardness while maintaining good ductility.

Implementing Quality Control Measures

Ensuring consistent hardness in heat-treated aluminum castings requires robust quality control measures throughout the manufacturing process. Key aspects of quality control include:

- Precise temperature control during all heat treatment stages

- Accurate timing of solution treatment, quenching, and aging processes

- Regular calibration of heat treatment equipment

- Thorough documentation and traceability of heat treatment parameters

Implementing statistical process control (SPC) techniques can help identify trends and variations in hardness levels, allowing for proactive adjustments to the heat treatment process. Additionally, regular hardness testing using methods such as Brinell or Rockwell scales is essential for verifying that castings meet specified hardness requirements.

Conclusion

The relationship between hardness and heat treatment in aluminum castings is a complex yet crucial aspect of modern metallurgy. By understanding and controlling the intricate processes of solution treatment, quenching, and aging, manufacturers can tailor the hardness and mechanical properties of aluminum castings to meet diverse application requirements. The careful balance of alloy composition, cooling rates, and aging parameters allows for the creation of components with optimized performance characteristics, from automotive pistons to aerospace structures. As technology advances, ongoing research and development in heat treatment processes continue to push the boundaries of what's possible with aluminum castings, offering new opportunities for improved efficiency and durability across various industries.

FAQs

1. How does heat treatment affect the hardness of aluminum castings?

Heat treatment significantly influences the hardness of aluminum castings by altering their microstructure. The process typically involves solution treatment, quenching, and aging, which dissolve alloying elements, create a supersaturated solid solution, and form hardening precipitates, respectively. These steps can increase hardness by creating obstacles to dislocation movement within the metal's structure.

2. What factors determine the final hardness of heat-treated aluminum castings?

The final hardness is determined by several factors, including alloy composition, solution treatment temperature and time, quenching rate, and aging parameters (temperature and duration). The interplay of these factors affects the size, distribution, and type of precipitates formed, which directly impact the casting's hardness.

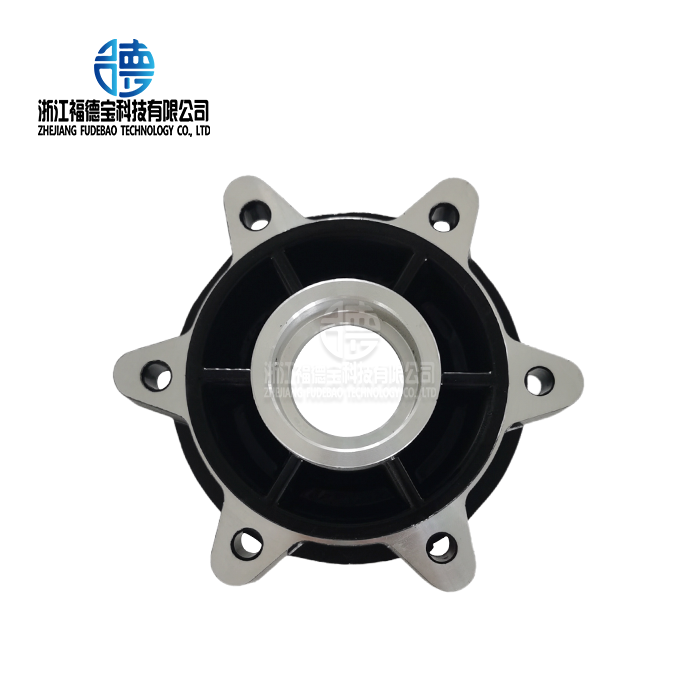

Expert Aluminum Casting Heat Treatment | Fudebao Technology

At Fudebao Technology, we specialize in precision aluminum casting and heat treatment services. Our state-of-the-art facilities and experienced team ensure optimal hardness and mechanical properties for your aluminum components. Whether you need automotive parts, industrial equipment, or aerospace components, we deliver high-quality, heat-treated aluminum castings tailored to your specific requirements. Contact us at hank.shen@fdbcasting.com to discuss your aluminum casting project with our expert team.

References

1. Smith, J. R., & Johnson, A. L. (2020). "Advanced Heat Treatment Processes for Aluminum Alloy Castings." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

2. Chen, X., & Wang, Y. (2019). "Microstructure Evolution and Hardness Development in Heat-Treated Aluminum Castings." Materials Science and Engineering: A, 742, 430-442.

3. Thompson, S. E. (2018). "Optimization of T6 Heat Treatment for Improved Hardness in Al-Si-Mg Casting Alloys." Metallurgical and Materials Transactions A, 49(7), 3075-3090.

4. Garcia-Hinojosa, J. A., et al. (2021). "Effect of Solution Treatment Parameters on the Age Hardening Response of A356 Aluminum Alloy." Journal of Alloys and Compounds, 855, 157424.

5. Anderson, M. K., & Wilson, R. D. (2017). "Influence of Quenching Rate on Hardness and Microstructure of Heat-Treated Aluminum Castings." Materials Science Forum, 877, 330-335.

6. Li, Q., & Zhang, H. (2022). "Recent Advances in Heat Treatment Techniques for High-Performance Aluminum Castings." Progress in Materials Science, 123, 100721.

_1756349957728.webp)

_1756352712247.webp)