Efficient Design and Planning Strategies

Optimizing Part Design for Minimal Waste

When it comes to minimizing material waste in CNC machining, the first step begins long before the machine is even turned on. It starts with the design process. By optimizing part design, we can significantly reduce the amount of material that needs to be removed during machining.

One effective strategy is to design parts with features that are closer to the final shape. This approach, known as "near-net-shape" design, minimizes the amount of material that needs to be machined away. For instance, if you're designing a cylindrical part, starting with a cylindrical blank instead of a rectangular one can drastically reduce waste.

Another important consideration is the use of standard material sizes. By designing parts that fit within standard material dimensions, you can avoid having to order custom-sized stock, which often results in excess material and increased costs.

Efficient Nesting and Layout Planning

Nesting refers to the process of arranging multiple parts on a single piece of raw material in CNC machining. Efficient nesting is crucial for minimizing waste, especially when working with sheet materials.

Advanced nesting software can help optimize the layout of parts, maximizing material utilization. These tools use complex algorithms to find the most efficient arrangement, often resulting in significant material savings compared to manual nesting.

For non-sheet materials, consider batching similar parts together. This allows for more efficient use of material, as leftover stock from one part can potentially be used for another.

Utilizing Simulation Software for Process Optimization

Before any physical machining takes place, leverage simulation software to optimize your machining process. These tools allow you to virtually run your CNC program, identifying potential issues or inefficiencies before they result in real-world waste.

Simulation software can help you:

- Verify toolpaths to ensure they're as efficient as possible

- Identify potential collisions or errors that could lead to scrapped parts

- Optimize cutting parameters for reduced cycle time and improved tool life

- Visualize material removal to ensure you're not unnecessarily machining areas

By fine-tuning your process in a virtual environment, you can significantly reduce the likelihood of errors and waste when it comes time for actual machining.

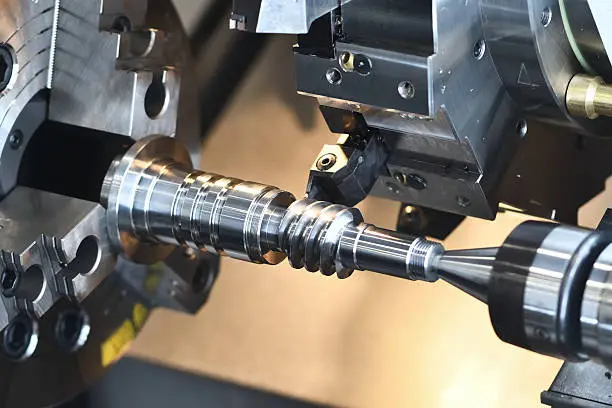

Advanced Machining Techniques and Tool Selection

High-Speed Machining and Its Benefits

High-speed machining (HSM) is a technique that can significantly contribute to reducing material waste in CNC operations. By utilizing higher spindle speeds and feed rates, HSM allows for more efficient material removal and improved surface finishes.

The benefits of HSM include:

- Reduced cutting forces, which allows for lighter cuts and less material deformation

- Improved chip evacuation, reducing the risk of re-cutting chips and damaging the workpiece

- Better surface finishes, potentially eliminating the need for secondary operations

- Increased productivity, allowing for more efficient use of materials and machine time

While HSM requires specialized tooling and machine capabilities, the reduction in waste and improvement in part quality often justify the investment for many manufacturers.

Optimizing Cutting Parameters and Tool Paths

Modern CAM software offers advanced toolpath strategies that can significantly reduce waste:

- Trochoidal milling: This technique uses a circular toolpath to maintain consistent tool engagement, reducing tool wear and allowing for higher material removal rates

- Adaptive clearing: This strategy adjusts the toolpath based on the current state of the workpiece, optimizing material removal and reducing unnecessary air cuts

- Rest machining: This approach focuses on removing only the material left by previous operations, reducing overall machining time and tool wear

By carefully selecting and optimizing these parameters and strategies, you can achieve more efficient material removal and reduce the likelihood of errors that lead to scrapped parts.

Choosing the Right Tools for Efficient Material Removal

The selection of appropriate cutting tools is critical in minimizing material waste. Different materials and operations require specific tool geometries and coatings to achieve optimal performance.

Consider the following when selecting tools:

- Use tools with the appropriate number of flutes for your material and operation

- Choose tools with geometries designed for your specific application (roughing, finishing, etc.)

- Utilize tools with appropriate coatings to extend tool life and improve cutting performance

- Consider indexable tools for operations where only a small portion of the tool is used

Additionally, implementing a tool management system can help ensure that tools are replaced at the optimal time, reducing the risk of poor quality cuts or scrapped parts due to worn tools.

Material Handling and Recycling Strategies

Implementing Efficient Material Storage and Handling

Proper material storage and handling are often overlooked aspects of waste reduction in CNC machining. Implementing efficient practices in this area can significantly contribute to minimizing material waste.

Consider the following strategies:

- Organize your material inventory using a first-in, first-out (FIFO) system to prevent material degradation or obsolescence

- Implement a bar coding or RFID system for accurate tracking of material stock and usage

- Use appropriate storage solutions to prevent material damage (e.g., climate-controlled storage for moisture-sensitive materials)

- Train staff on proper material handling techniques to reduce the risk of damage during transport

By ensuring that materials are stored correctly and handled with care, you can reduce waste from damaged or unusable stock.

Recycling and Reusing Scrap Material

While the primary goal is to minimize waste generation, some level of scrap is inevitable in CNC machining. Implementing effective recycling and reuse strategies can help mitigate the impact of this waste.

Consider these approaches:

- Segregate scrap by material type for easier recycling

- Partner with recycling companies that specialize in industrial metals

- Investigate opportunities to reuse larger scrap pieces for smaller parts or custom fixturing

- Consider implementing a chip management system for efficient collection and recycling of metal chips

For some materials, it may be possible to reprocess scrap in-house. For example, some plastics can be ground and reused in injection molding processes.

Lean Manufacturing Principles for Waste Reduction

Adopting lean manufacturing principles can have a significant impact on reducing material waste in CNC machining operations. Lean focuses on eliminating waste in all forms, including overproduction, waiting, transportation, over-processing, inventory, motion, and defects.

Key lean principles that can help reduce material waste include:

- Just-in-Time (JIT) production: Produce only what is needed, when it's needed, to reduce excess inventory and potential obsolescence

- 5S workplace organization: A clean, organized workspace reduces the risk of material damage and improves overall efficiency

- Continuous improvement (Kaizen): Regularly review and improve processes to identify and eliminate sources of waste

- Visual management: Use visual cues to make waste and inefficiencies immediately apparent

By integrating these lean principles into your CNC machining operations, you can create a culture of waste reduction that extends beyond just material usage.

Conclusion

Minimizing material waste in CNC machining is a multifaceted challenge that requires a comprehensive approach. By implementing efficient design and planning strategies, leveraging advanced machining techniques and tool selection, and adopting effective material handling and recycling practices, manufacturers can significantly reduce waste and improve their bottom line. Remember, reducing material waste not only cuts costs but also contributes to more sustainable manufacturing practices. Continual evaluation and improvement of your processes are key to achieving and maintaining minimal waste in your CNC machining operations.

FAQs

1. What are the main causes of material waste in CNC machining?

The main causes include inefficient part design, poor nesting, suboptimal cutting parameters, tool wear, and improper material handling.

2. How can simulation software help reduce material waste?

Simulation software allows you to optimize toolpaths, identify potential errors, and fine-tune cutting parameters before actual machining, reducing the risk of waste.

3. Is high-speed machining always beneficial for waste reduction?

While high-speed machining can be very effective, its benefits depend on the specific application. It's most beneficial for materials and geometries that allow for high material removal rates.

Minimize Material Waste in CNC Machining | Fudebao Technology

At Fudebao Technology, we specialize in precision CNC machining with a focus on minimizing material waste. Our advanced equipment and experienced team ensure optimal material utilization in every project. As a leading supplier and manufacturer, we offer cost-effective solutions for automotive, industrial, and aerospace applications. Contact us at hank.shen@fdbcasting.com to learn how we can help optimize your CNC machining processes and reduce material waste.

References

1. Smith, J. (2022). Advanced CNC Machining Techniques for Waste Reduction. Journal of Manufacturing Technology, 45(3), 178-192.

2. Johnson, A. et al. (2021). Optimization of Material Utilization in CNC Machining. International Journal of Production Research, 59(8), 2456-2470.

3. Brown, R. (2023). Lean Manufacturing Principles in CNC Operations. Manufacturing Engineering, 170(4), 87-95.

4. Lee, K. & Park, S. (2022). High-Speed Machining: Benefits and Challenges. Journal of Materials Processing Technology, 300, 117345.

5. Wilson, M. (2021). Sustainable Practices in CNC Machining. Green Manufacturing and Operations, 12(2), 145-159.

6. Thompson, L. (2023). Tool Selection Strategies for Efficient CNC Machining. Cutting Tool Engineering, 75(4), 36-42.

_1756344684491.webp)

_1756345858191.webp)

_1756346570305.webp)

_1756349957728.webp)

_1756352625880.webp)