Optimizing Component Geometry for Low Pressure Casting

When designing components for low pressure casting, it's crucial to consider the specific requirements and limitations of the process. Let's explore three key aspects of optimizing component geometry:

Wall Thickness Considerations

One of the primary advantages of low pressure casting is its ability to produce components with thin walls. However, maintaining consistent wall thickness is crucial for ensuring uniform solidification and preventing defects. As a general rule, aim for a minimum wall thickness of 3-4mm for aluminum alloys, and avoid abrupt changes in thickness that could lead to hot spots or shrinkage porosity.

Draft Angle Design

Proper draft angles are essential for easy removal of the cast component from the mold. For low pressure casting, a minimum draft angle of 1-2 degrees is recommended, with larger angles for deeper cavities or surfaces perpendicular to the parting line. Incorporating adequate draft angles not only facilitates easier part removal but also improves surface finish and reduces the risk of defects.

Radius and Fillet Optimization

Sharp corners and edges can lead to stress concentrations and potential defects in cast components. To mitigate these issues, incorporate generous radii and fillets into your design. For low pressure cast components, a minimum radius of 2-3mm is recommended, with larger radii for thicker sections or high-stress areas. This approach not only improves the structural integrity of the part but also enhances metal flow during the casting process.

Material Selection and Alloy Considerations

Choosing the right material and alloy is crucial for the success of low pressure cast components. Let's delve into three important aspects of material selection:

Alloy Compatibility with Low Pressure Casting

Not all alloys are suitable for low pressure casting. Aluminum alloys, such as A356 and A357, are commonly used due to their excellent fluidity and mechanical properties. When selecting an alloy, consider factors such as castability, strength-to-weight ratio, and corrosion resistance. Consult with metallurgists or material specialists to ensure the chosen alloy meets your specific requirements and is compatible with the low pressure casting process.

Thermal Properties and Solidification Behavior

Understanding the thermal properties and solidification behavior of your chosen alloy is crucial for designing efficient gating systems and optimizing the casting process. Consider factors such as the alloy's melting range, thermal conductivity, and solidification shrinkage. This knowledge will help you design appropriate feeding systems and determine optimal process parameters, such as mold temperature and filling rate.

Post-Casting Heat Treatment Options

Many low pressure cast components benefit from post-casting heat treatments to enhance their mechanical properties. When selecting an alloy, consider its response to heat treatment processes such as solution treatment, quenching, and aging. Some alloys, like A356 and A357, are particularly well-suited for heat treatment, allowing for significant improvements in strength and ductility. Factor in the potential for heat treatment when designing your component and specifying material properties.

Gating and Feeding System Design

The design of the gating and feeding system is critical for producing high-quality low pressure cast components. Let's explore three key aspects of this crucial design element:

Optimal Gate Placement and Sizing

Proper gate placement and sizing are essential for achieving uniform filling and minimizing turbulence during the casting process. In low pressure casting, gates are typically located at the bottom of the mold cavity to take advantage of the controlled, bottom-up filling. Consider using multiple gates for large or complex components to ensure even distribution of metal. Size the gates to maintain a filling velocity of 0.3-0.5 m/s, which helps prevent oxide formation and gas entrapment.

Riser Design and Placement

Risers play a crucial role in compensating for solidification shrinkage and ensuring sound castings. In low pressure casting, the controlled filling process allows for more efficient use of risers compared to gravity casting. Design risers with a modulus (volume-to-surface area ratio) 1.2 times larger than the heaviest section they feed. Place risers strategically to feed isolated thick sections and ensure directional solidification towards the riser.

Venting and Overflow Systems

Effective venting is crucial for removing trapped gases and ensuring complete mold filling. Design vents at the highest points of the mold cavity and along parting lines. For complex geometries, consider using overflow systems to capture the first metal entering the mold, which may contain oxides or impurities. Properly designed venting and overflow systems help reduce porosity and improve overall casting quality.

Conclusion

Mastering the key design rules for low pressure cast components is essential for achieving high-quality, defect-free parts with optimal mechanical properties. By focusing on optimizing component geometry, carefully selecting materials and alloys, and designing effective gating and feeding systems, manufacturers can fully leverage the advantages of low pressure casting. As with any manufacturing process, continuous improvement and collaboration between designers, engineers, and foundry experts are crucial for pushing the boundaries of what's possible with low pressure casting technology.

FAQs

What are the main advantages of low pressure casting?

Low pressure casting offers benefits such as reduced porosity, improved mechanical properties, and the ability to produce thin-walled components with complex geometries.

How does low pressure casting differ from high pressure die casting?

Low pressure casting uses lower pressures and slower filling rates, resulting in less turbulence and better control over the solidification process compared to high pressure die casting.

What materials are commonly used in low pressure casting?

Aluminum alloys, such as A356 and A357, are frequently used in low pressure casting due to their excellent fluidity and mechanical properties.

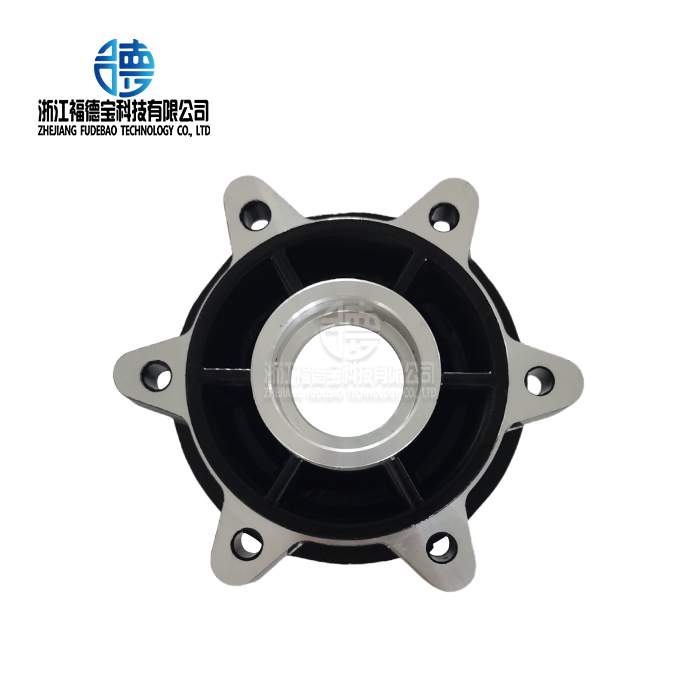

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing high-quality low pressure cast components for various industries. Our state-of-the-art facilities and experienced team ensure precision manufacturing and adherence to the key design rules discussed in this article. As a leading low pressure casting supplier and manufacturer, we offer comprehensive solutions from design optimization to final production. Contact us at hank.shen@fdbcasting.com to learn how we can support your casting needs.

References

Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

Kaufman, J. G., & Rooy, E. L. (2004). Aluminum Alloy Castings: Properties, Processes, and Applications. ASM International.

Grassi, J., Campbell, J., Hartlieb, M., & Major, F. (2009). The Ablation Casting Process. Materials Science Forum, 618-619, 591-594.

Bonollo, F., & Gramegna, N. (2015). The MUSIC guide to key-parameters in High Pressure Die Casting. Assomet Servizi SRL.

ASM International. (2008). Casting Design and Performance. ASM International.

Brown, J. R. (1999). Foseco Non-Ferrous Foundryman's Handbook. Butterworth-Heinemann.

_1756349862928.webp)

_1756350046757.webp)